When I started doing inspections, I purchased a licence to the ISO2859-1 standard before I even received the first payment from my client. Working on the basis of irrefutable statistics appeared to be indispensable. It seems like the … [Read more...]

The advantage of a dedicated inspection room

Many Chinese factories have no dedicated area for third-party QC inspections. We often sit down in the packing department (because that's where the cartons generally are), or in a meeting room (because that's where we can get a large table … [Read more...]

How to prepare a QC inspection checklist [infographic]

I love to help importers define their product requirements in details. Engineers working on new product developments call it a "product quality manual". In the quality assurance industry, we call it a "QC inspection checklist". I have … [Read more...]

Making a hard-to-copy product in china

There is a line that I heard several times, and that makes me cringe: "well, our product is difficult to manufacture, but the good side is that it will be hard to copy". I don't give ANY value that that "good side". If the product is … [Read more...]

Preparing specifications for production in China

In 80% of cases, importers do not spend enough time preparing the specifications of the products they want to make in China. They usually work on the basis of sample, but they forget about all the "details" (the bill of materials, the … [Read more...]

How to work with Chinese suppliers

As many first-time importers notice, working with a Chinese supplier necessitates a change in habits: It is very important to define the product requirements in the smallest details, including the labeling and the packaging. Quality … [Read more...]

How does a factory audit work? [infographic]

A few months ago, we illustrated how random inspections work, and we got very positive feedback. This time we designed an infographic about the way a factory audit works in China and other low-cost Asian countries: We tried to put … [Read more...]

Production delays and quality problems often come up together

Over the past couple of months, I have noticed the same phenomenon in several situations. Let's say an importer has placed an order for 4 references to be shipped out together. The supplier announces that one of them will be ready one week … [Read more...]

Elements of a China sourcing strategy

I ran a guest post on the China Law Blog that sums up most of what I have learned about quality assurance in China so far. The article is called The Five Steps To Successfully Buying Product From China. It touches on seemingly separate … [Read more...]

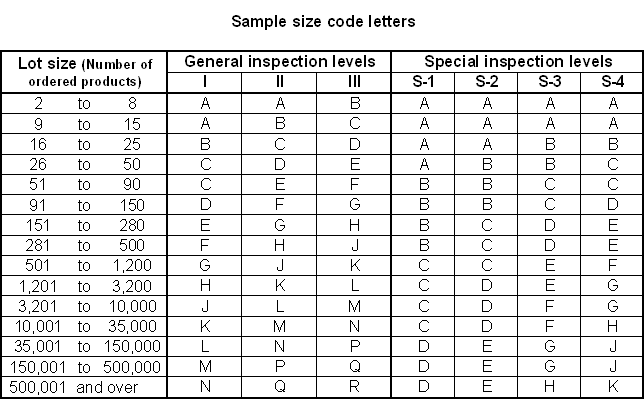

ISO 9000 factory audits for your China suppliers

Factory audits in China and other Asian countries are often (loosely) based on a checklist inspired by the ISO 9000 series. That means the main part of these audits consists in looking for holes in the factory's quality system. Why are … [Read more...]

- « Previous Page

- 1

- …

- 130

- 131

- 132

- 133

- 134

- …

- 154

- Next Page »

![How to prepare a QC inspection checklist [infographic]](https://qualityinspection.org/wp-content/uploads/2011/01/shutterstock520432087-960x627.jpg)