As I wrote in How to Check Lab Test Certificates/Reports?, I guess that 10-30% of the product certifications given by Chinese suppliers to their customers are fake. A "fake" certification is often a real certificate that was issued … [Read more...]

7 Signs of a Poorly Managed Chinese Factory

Before you can evaluate a Chinese manufacturer's quality level or engineering capabilities, one thing should jump at you: are they well managed? I made a list of 7 signs that you should observe when touring a plant. Let's start at the … [Read more...]

Setting up Injection Molding Machines in China

Many importers complain about the lack of technical expertise in Chinese factories. In most cases, there is one key engineer who "works his magic". And, when he is gone, really bad things start to come out. Setting up injection molding … [Read more...]

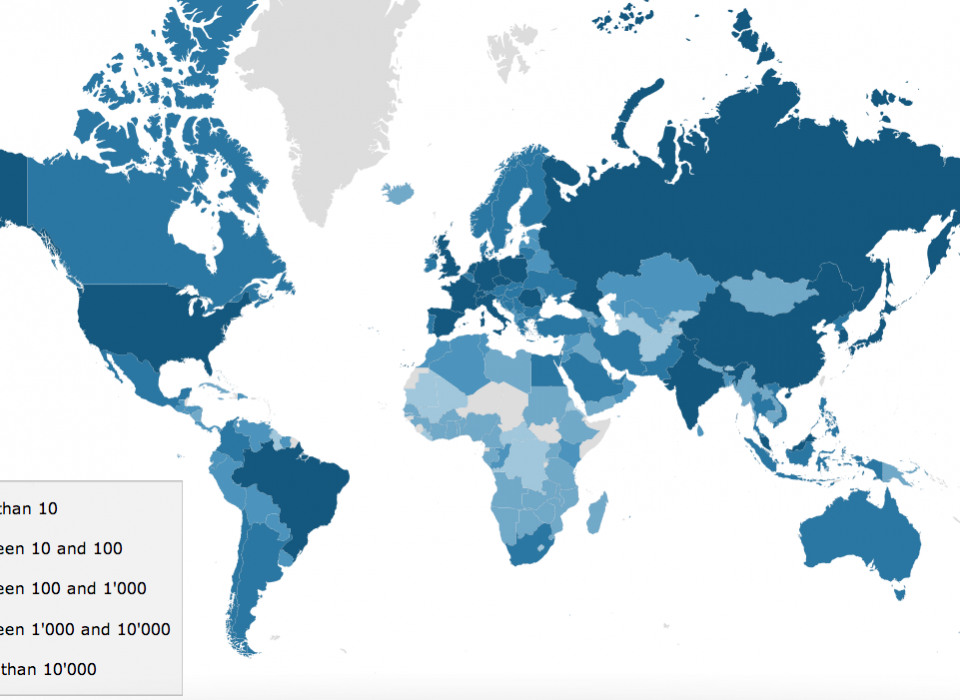

ISO 9001: More Popular in China than in the US or Japan

The International Organization for Standardization (ISO) shows how many companies are currently ISO 9001 certified in each country: And the highest number of ISO 9001-registered companies is... China. And that number is on the … [Read more...]

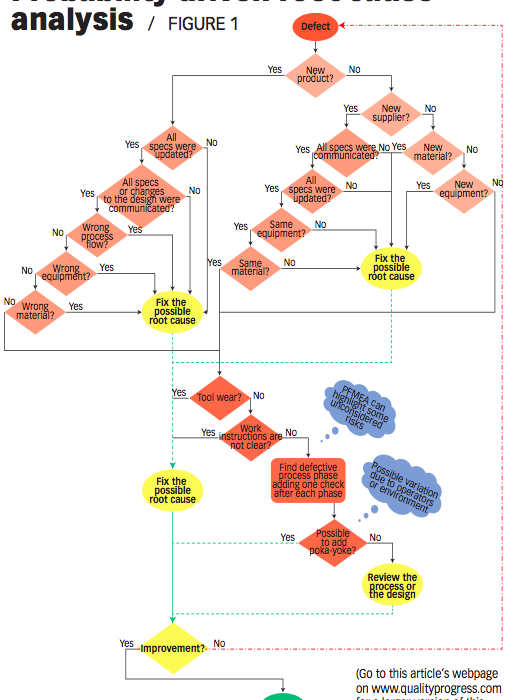

A simple method to find a production problem’s root cause(s)

The biggest frustration I have with Chinese engineers is their lack of interest in fixing the root cause of a problem. Let’s say a machine’s printing mechanism deviates to the right, and their customer’s logo is totally disfigured. If … [Read more...]

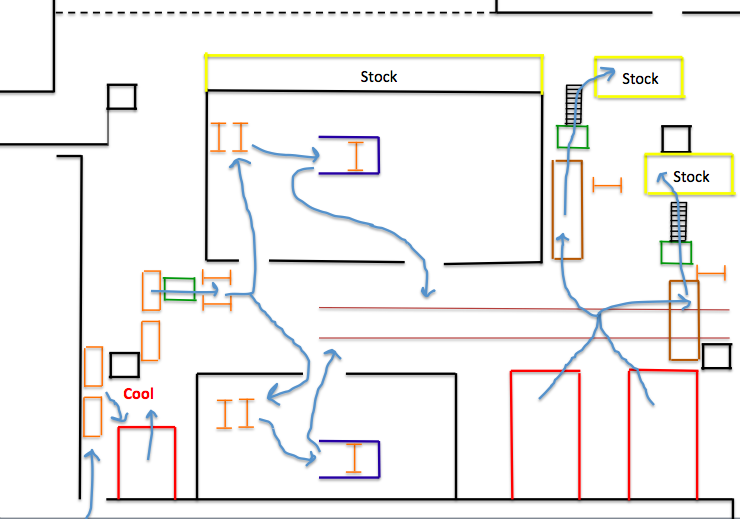

Suggestions for factory improvements in China: make it visual

Last week I spent two days in a factory, studying a process and thinking of ways to improve it without spending any big money. It made me realize something very important about communication with Chinese people. They are happy to … [Read more...]

Chinese factory TURNAROUND: is it good to hire new managers?

When a factory gets sold, the new owner generally brings a new general manager (GM) in. And what does the GM do? He evaluates the top managers and seeks to replace the under-performers. This is expected in a typical factory … [Read more...]

History of Manufacturing Practices in the US, Japan, and China

Over the past few weeks, we have been working hard on this new infographic with our favorite designer. Do you agree with that message? Help us and pass the word! (And a Chinese version can be found here). *** TRANSCRIPT A BRIEF … [Read more...]

Beware of MANAGER inflation in your China buying office

Sometimes I visit a buying office with a dozen people, and most of them have "manager" somewhere in their title. The heads of functions (purchasing, QC, accounting...) are "managers", even though their teams are quite small. Then there … [Read more...]

Push your Chinese Factories to Learn about LEAN Manufacturing!

This month, the magazine Chief Executive China did a cover story on lean manufacturing. Their editors sensed an emerging interest from local companies to lean from world-class manufacturers. The leading article of their cover story is … [Read more...]

- « Previous Page

- 1

- …

- 8

- 9

- 10

- 11

- 12

- …

- 14

- Next Page »