Whenever some product attributes can be measured, statistical tools can help understand the situation, prioritize improvement efforts, and even help those improvement efforts. For example, if you measure your product's size, thickness, or … [Read more...]

What KPIs for Your Procurement Office in China?

A few months ago I asked Alexandre Godvin a few questions about the KPIs of purchasing departments. He listed 4 common types of KPIs: Margin % Time to market, or average delay Supplier quality Social/environmental compliance If … [Read more...]

China Management Best Practice: Always Give Some Context

One thing that always amazes me is the lack of understanding of the average Chinese worker of his/her context. Let me give a few examples and it will become clear. In the West, the airline counter lady can pull a lot of information … [Read more...]

What Good Assembly Work Instructions Look Like

A few weeks ago, I wrote How To Ensure Quality In Chinese Factories By Writing Work Instructions. (By the way, we have recently published a number of resources on the CMC website. If you are interested in good factory management, you … [Read more...]

How To Know if Your China Factory Is Good?

I hear buyers talk about their "good suppliers" and their "bad suppliers", yet they are often unable to pinpoint what makes them "good" or "bad". Maybe one factory has better "systems". But few buyers actually take the time to look into … [Read more...]

KPIs and IT Tools of Purchasing Departments (Expert Q&A)

I had the opportunity to ask a few questions to Alexandre Godvin, who has a particular perspective on the KPIs and IT tools of purchasing departments. Alexandre is the founder and CEO of Winddle, a turnkey, modern, and collaborative … [Read more...]

Good Visual Management Changes How Internal Auditing Gets Done

The concept of visual management is often misunderstood, yet it is quite an important topic. I found a great post by Mark Graban entitled Moving from “Visuals” to “Visual Management” and to Broader Lean Thinking. He points out that … [Read more...]

Training your China Factory before Production Starts

Most importers take the following measures in order to ensure the factory understands what to make: Approvals of pre-production samples; Some guidelines about the product and its packing, something gathered in a technical … [Read more...]

IT Systems for Managing your China Procurement

In this article I am going to introduce a few specialized IT systems that can be quite useful for procurement/sourcing offices. But first let's mention what most organizations of a certain size are currently using. The need for an ERP An … [Read more...]

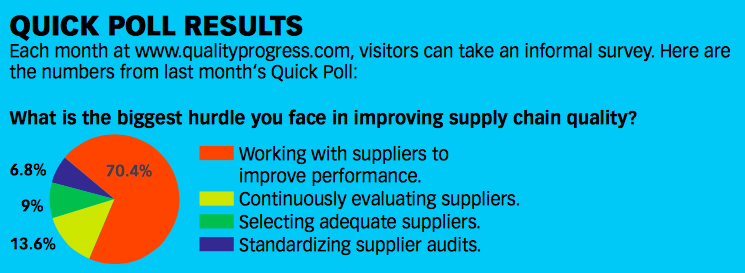

Improving Supplier Performance is Buyers’ Biggest Hurdle

I saw this poll result in a recent issue of the Quality Progress magazine (a publication by the American Society for Quality): Why is it so difficult for companies to push their suppliers to improve performance? I can think … [Read more...]

- « Previous Page

- 1

- …

- 5

- 6

- 7

- 8

- 9

- …

- 14

- Next Page »