Anybody who has imported products from China can attest that the planning process of most manufacturers is not exactly under control. The sad reality is, buyers are often happy when a shipment is “only” 10 days behind the promised date.

Anybody who has imported products from China can attest that the planning process of most manufacturers is not exactly under control. The sad reality is, buyers are often happy when a shipment is “only” 10 days behind the promised date.

But where does this lack of precision come from? Is it the result of over-enthusiastic salespeople? Not only.

In this article I listed the 7 most serious issues I have noticed in many Chinese factories.

1. Lack of stability

There are always urgencies — customers screaming louder than the others, that is. So the boss puts their orders on top of the priority list. As a result, production people are constantly told to “expedite this one”, and then “oh actually this one is even more urgent”, and so on.

Why is it a problem? Because it causes a severe loss of efficiency in production.

A stable planning, on the contrary, allows the factory to minimize the number of changeovers, to keep staff fully utilized, to minimize confusion, etc. In the end, it means lower costs.

2. No standard timing for recurring operations

How does a serious manufacturer quote a new product? By checking the cost of the bill of material, and by estimating the time one piece will spend at each process. This process can be relatively precise by tracking the time it takes to make samples and by applying a few rules of thumb.

Once a production runs regularly, it is also good to have an industrial engineer perform simple time & motion studies. The main purpose should not be to refine the amount the workers should get paid, but to allow for a finer planning process. (And it also allows the production department to calculate their efficiencies.)

But what about the vast majority of Chinese factories that don’t make the effort to forecast process times in a scientific manner? They are easily 20% off on any given operation — and sometimes more than 100% off! (Ever wondered why prices go up so often after production has started?)

3. Excessive batch sizes

Chinese factory owners are obsessed with paying the absolute lowest price they can for components, and it often pushes them to purchase large quantities at a time — sometimes we see 6 or 8 months of inventory for certain components or accessories.

Unfortunately, these larger batches often take longer to make. So a few days (or weeks) are wasted right here. And then, what happens internally after the components are in stock? The factory tries to gain production efficiency by making batches that are larger than orders on hand. Same logic.

Not only does it NOT save them money, but it means production takes even longer.

4. No understanding of the whole system

If you want to see if a production manager is smart, ask him if he has identified any bottlenecks (there is always at least one), and what actions he has taken to elevate their capacity.

Similarly, production managers typically have no understanding of the impact of WIP (Work In Process) inventory on production timing. A mathematical relationship dictates that more WIP means longer lead times.

Finally, there is sometimes no buffer. Many factories add 4 to 8 days in the planning, because they know “shit happens”, but some unsophisticated manufacturers don’t even think of this.

5. Lack of follow up

Good factories run, at the very least, a weekly review of all orders due for shipment in the coming days. The idea is to review their status and to take appropriate actions if delays are probable. But many factories have no regular meeting. That’s a mistake.

Actually, I have found that people love meetings. Unstructured meetings called ad hoc to discuss a burning issue, that is. But regular meetings to discuss the situation based on data? That’s another story. It is often necessary for the general manager to force it into his staff’s schedule.

6. Sequential preparation by different individuals/departments

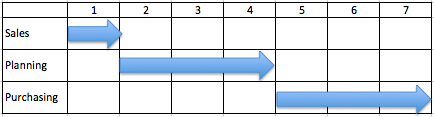

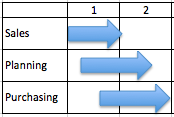

I recently reviewed the planning process of a factory that takes 7 days between receipt of a customer’s PO and confirmation of order by suppliers. The sales team needed one day to prepare the information in the right format, then the planning & purchasing teams needed several days to prepare the bill of materials, check the stock, inform suppliers, etc.

Not only do their internal processes need a solid dose of simplification and standardization, but each service waits until the previous one has completed its job. Part of the solution is concurrent processing, as illustrated below.

7. No coordination with the HR manager

If orders pick up noticeably, it is good to start hiring more production operators a few weeks before. This is common sense, but apparently common sense is missing in many organizations. The HR manager should get a summary of upcoming orders at least once a week, to adjust the headcount.

—

Maybe some readers have observed other severe issues around production planning?