I often tell importers not to focus too much on the factory-gate price when selecting a supplier. There are so many other elements to take into account!

I often tell importers not to focus too much on the factory-gate price when selecting a supplier. There are so many other elements to take into account!

Recently I had the chance to attend a presentation (in a FCCIHK seminar) that emphasized this point. The speaker was Michael Mayringer, director of global supply chain, Bombardier Recreational Products (BRP), Powertrain division.

His company’s changes in purchasing strategy nicely illustrate three levels of sophistication:

Level 1: re-active purchasing price analysis

Until about 10 years ago, BRP’s “cost reduction programs” were mainly:

- Tactical “price negotiation”

- Very much focused on labor cost

This is the way most SMEs still interact with their suppliers.

Level 2: focus on cost, not just price

In 2001, BRP decided to optimize the material cost of its products in a more structured manner. They started to focus on cost instead of price.

They introduced cost analysis methods:

- Purchasing Price Analysis

- Value Analysis & Re-design

- Cost Process validation at supplier

They worked on establishing trust & openness with their suppliers. The objective was open book cost break downs. (Note that BRP is a rather large company, and that it might be very difficult for an SME to achieve the same objective).

These activities proved to be successful for a few years, but the returns were clearly diminishing. So BRP took a more pro-active approach.

Level 3: pro-active enterprise costing

They asked themselves this question:

Can we implement a holistic business process (Enterprise Costing) capturing the entire product lifecycle and involving the whole value chain as a sustainable strategy?

They had four objectives:

- Develop better cost-calculation processes, know-how, transparency, and management.

- Heavily focus on costs during the product development phase.

- Better align their technology, manufacturing, and sourcing strategies.

- Involve supply chain partners more early and more effectively.

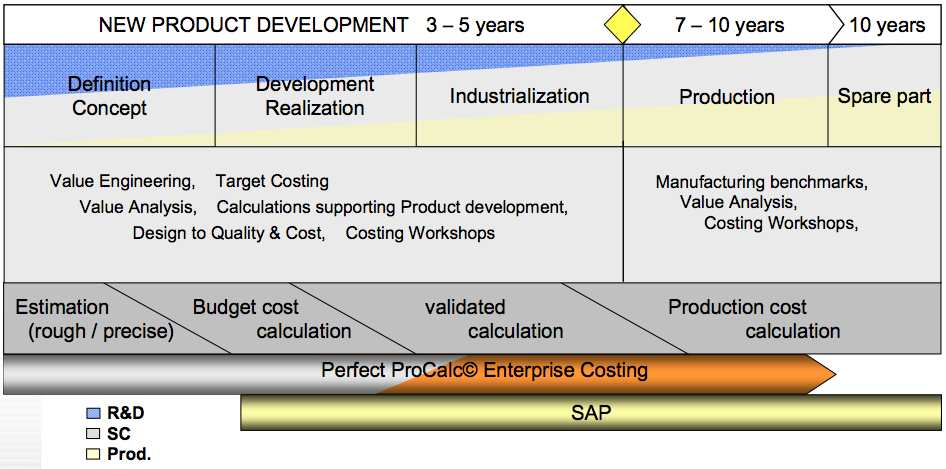

Here is how they illustrate this new approach:

This approach is based on several elements:

a. Maximum value proposition

- Intensive early supplier involvement in product development.

- Rigorous application of “design to quality & cost”

- Search for improved customer satisfaction

b. New form of organization

- Cross-functional approach (horizontal based on type of product, not vertical based on functions).

c. Integrated part of Global Sourcing Strategy and Supplier Management

- The most cooperative suppliers were moved up to the level of strategic supplier or even alliance partner.

d. Innovation

- New products and new technologies were developed.

This third level is clearly a big step toward best practices. Can’t SMEs get a lot of inspiration from this example?

Hello Renaud one more VERY valuable post! Thanks a lot!

Could you explain what is the difference between “costing workshop” and “manufacturing benchmark” in the illustration of the process? I believe here we are talking about the “sourcing” phase right? Thank you.

Thanks Alex.

From my understanding:

– Costing workshop = pre-production meetings with suppliers and designers, to find ways of reducing costs.

– Manufacturing benchmarks = once production is ongoing, certain targets (for quality, cost, delivery) are set and need to be approached/reached.