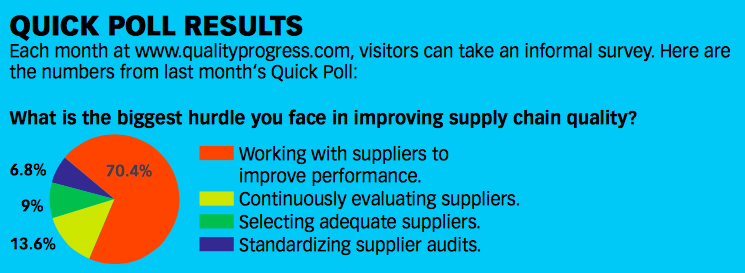

I saw this poll result in a recent issue of the Quality Progress magazine (a publication by the American Society for Quality):

Why is it so difficult for companies to push their suppliers to improve performance? I can think of four reasons.

First, the buyer didn’t make good sourcing decisions. The supplier might be too large (and the buyer might not represent a significant part of the supplier’s business), or the supplier’s boss is very short-term focused and doesn’t care about improvement.

Second, the buyer’s management systems, including the supplier evaluation system, are not effective in driving suppliers to adopt desired behaviors. For example, many large companies treat their suppliers like enemies (their purchasers typically ask for price decreases in the 2-8% range every year, disrespective of the supplier’s cost structure), and on the other hand ask for cooperation and openness for improvement initiatives. Suppliers are not dumb. If purchasers use every piece of information to request a discount, the response is to disclose as little as possible.

Third, the supplier truly wants to improve performance, but its staff is constantly busy putting out fires. This is one of the first things we address when working as consultants when fixing a factory. The three steps outlined below are necessary:

- Shift the responsibility of the day to day running of operations onto the team leaders and supervisors.

- Middle management should mostly work on proactive improvement initiatives (training programs, introduction and implementation of new management systems…)

- Set up a dedicated team that focuses purely on longer-term initiatives.

Fourth, the buyer is not helping in the right areas. They need to improve quality? Maybe their issues are due to poor maintenance. They need to cut costs? Maybe they reduce their high cost of rework and scrap, which are due to poor quality. They have late delivery problems? Maybe this situation is caused by a low attractiveness to workers, which stems from misguided HR policies.

It can be difficult for a customer to recognize where a supplier really needs help. As a general rule, you should assume Chinese factories lack the following four critical skills:

- HR management

- Equipment maintenance

- Industrial engineering

- Quality engineering

In conclusion, working with suppliers to improve their performance is a challenge, but 3 or the 4 reasons I listed above are related to the buyer’s organization. You might need to look in the mirror and change your practices first.