More and more products (both consumer goods and for industrial/commercial use) contain electronic parts – from dishwashers to remote controls and from small toys to functional MRI devices. If this is the case for some of the products you develop/buy, you need to know a few basics. This is why we prepared this series of electronics videos.

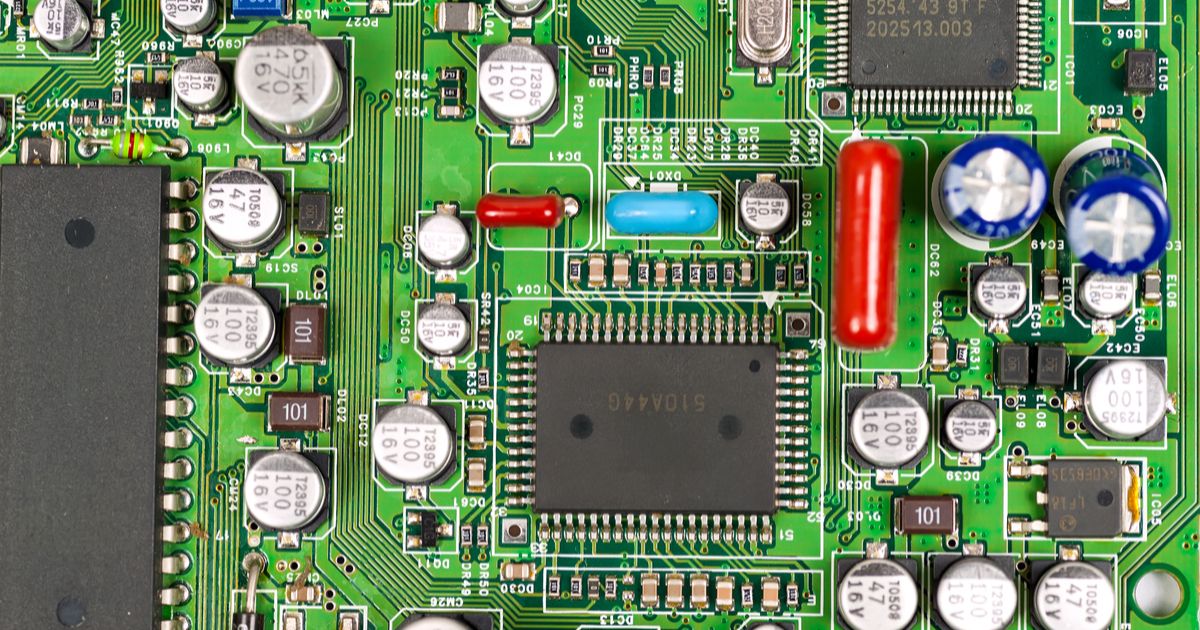

1. Printed Circuit Board Basics

Topics covered:

- Difference between a PCB and a PCBA

- PCB construction (the tracks; the layers: silkscreen, solder mask, copper, substrate)

2. The SMT process, part 1

The process of placing and soldering components on the PCB was covered in this video and the next two. In this one, we provide an overview of the Surface Mount Technology process, and we cover these SMA steps:

- Solder paste application on the PCB boards (typically in the shape of a board), and how the stencils are supposed to function (with illustration)

- Component placement based on fiducial marks – including the main types of pick & place (chip shooter, flexible placer), the most common vacuum nozzles & grips, and automated inspection methods )top vision, and AOI).

3. The SMT process, part 2

In this second video, we explain how these steps work:

- Reflow soldering (heating & cooling phases)

- Cleaning of the solder flux residue, and some examples of situations to avoid

4. The SMT process, part 3

Finally, we look at electrical testing, an essential element for confirming the PCBAs have been made properly.

The main types of in-circuit testing are:

- Flying probe

- Manufacturing defect analyzer

- Automated X-ray inspection

- First off sample inspection (with a microscope)

- Functional testing

- Burn-in testing

5. PCBA inspection methods, and common defects

The most frequent defects come from these causes:

- Solder paste issues – which can be detected by checking the solder place process for stencil alignment, checking the squeegee speed & pressure

- Pick & place issues such as loss of vacuum, short or worn nozzles, sticking nozzles, high reject rate at inspection, and ESD damages to components and/or PCB.

- Wave solder issues such as bridging, insufficient solder on topside or bottom fillet, de-wetting or non-wetting, solder voids, solder skip, icicles and flags/horns, solder on mask, etc.

We give lists of common causes for all these issues. Those are some of the points we check when we audit an EMS supplier.

6. Reliability testing for electronic products

Reliability testing, including HALT and HASS testing, is very common on electronic products. You don’t want them to stop functioning very fast after they are put to use!

We explain what reliability and durability mean, at a high level. And we cover the three most common causes of product failure:

- Temperature and humidity, with examples of environmental testing

- Vibration

- Mechanical shock

***

I hope you are now better equipped for working with PCB, PCBA, and electronic assembly manufacturers! We will probably go into more depth and extend this series of videos later. Please let us know if you have any requests for new electronics videos covering different topics by sharing your ideas as a comment below.

Lithium-Ion Battery Safety Guidelines For US Imports

Sofeast’s Lithium ion battery safety guidelines for US imports whitepaper is aimed at manufacturers who are producing goods requiring these batteries in China and Asia and seeking to ship them to the USA for sale. In it, we cover everything you need to know about shipping these batteries to the USA, including recalls, product & transport safety, compliance recommendations, and more.

Get your free copy by hitting the link or button below: