Find out where you need to be with new product designs before you approach Chinese manufacturers. We go through why immature designs are so risky and the work involved in getting designs that can be ‘industrialized,’ as well as pointing out some common red flags that will show you that your designs aren’t as ready as they should be.

Prefer listening to reading?

What do we mean by mature product designs?

Mature product designs are closer to being industrialized. New products always have some uncertainty for manufacturers because they haven’t been manufactured before, but if designs are too vague or half-baked the manufacturer won’t take you seriously because so many elements are unclear and it can’t be manufactured. They may not even want to ‘waste time’ quoting for the job because they see it as too risky or too vague. Therefore, product designs need to be quite clear on what the product looks like and how it functions and you may want to have CAD designs in hand, for example, so you have some work to do with product designers, electronic and mechanical engineers, firmware designers, etc, to get to mature designs. (01:24)

Don’t ignore important phases and milestones in the NPI process.

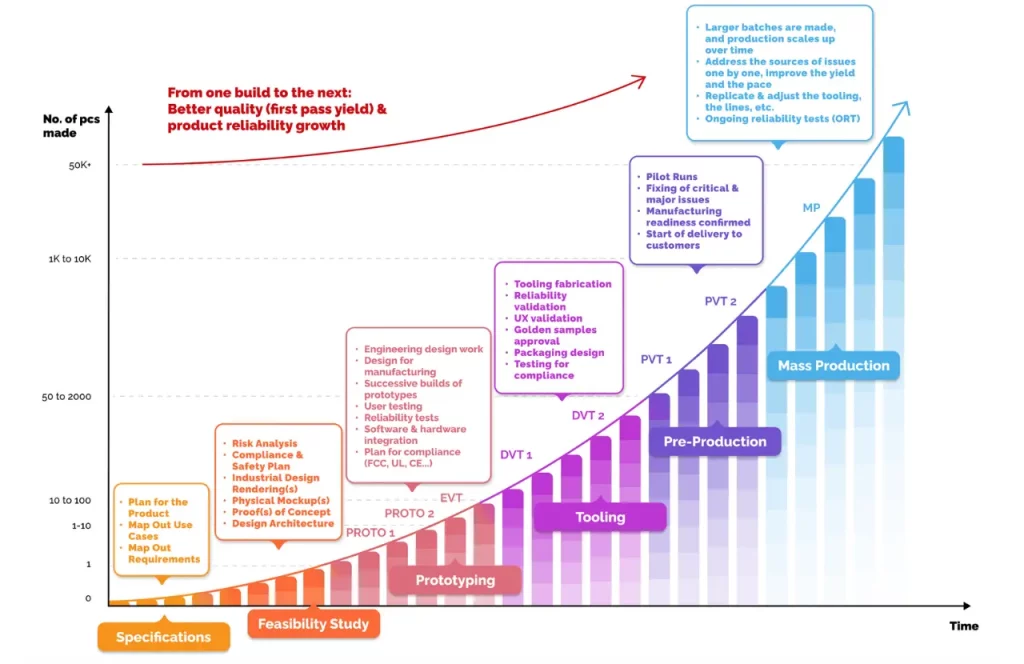

We divide the NPI process into 6 phases, and it’s important not to skip any if you’re trying to reduce risks and increase your chances of getting into production on time, on budget, and at the required level of quality and reliability.

The early phases of devising the specifications and running a feasibility study will help you create mature product designs because you will need to:

- Document the product’s requirements

- Identify key components and those which need to be custom-designed

- Start deciding on materials, surface finishing, and technologies

- Consider tolerances

- Come up with and think about how to overcome the challenges that come with the design

- Etc.

The feasibility study in particular will address most of the above and reduce risks, address challenges, and reduce the unknowns about your product. This information gets translated into your product designs and results in more mature designs. (04:54)

What the average Chinese manufacturer will need from you before they can get started.

An early CAD design without tolerances and CMF information is good for seeing aesthetics, but it’s still probably not mature enough for the average Chinese manufacturer. They will want to know:

- Tolerances

- Colors

- Finish

- Materials used

- CTQ points

Chinese manufacturers’ business model is to produce products, so they need a ready-to-go product design which has been prototyped with several iterations, has been user, performance, reliability and durability tested, and has been validated as ready to go into production. This means you need to know exactly where you are in the NPI process and you have done a lot of engineering work and product development as well as having mature designs. (07:30)

Approaching suppliers in the right way.

When we help customers with this we probably won’t accept a sketch on a napkin, but if you have done a lot of work from the first 3 NPI process phases (specifications, feasibility study, and product development work and prototyping), our next step is to get in touch with specialized component and material suppliers who will feed back on the product concept in relation to if your product seems feasible, its challenges, and if the quantities you propose to manufacture seem attractive enough.

For example, if the product needs a certain type of ceramic that can withstand a particular stress, ceramic suppliers will be contacted with some rough product details to test the water and see if this is something they feel is feasible. They also need to be told rough purchase amounts, so we will discuss your proposal for regular amounts and annual sales with you, too, and it’s important that your estimates of order quantities are large enough to attract suppliers.

When CAD drawings have been made later on we also suggest sharing them with the same suppliers who will provide further feedback on the designs and if they have the capabilities to manufacture the parts required. If so, getting them to take your order should be possible at this point. (09:45)

Is there a risk that a ‘bad’ manufacturer might take your project with immature designs anyway, leading to failure and wasted time and money?

Some Chinese manufacturers may be overly optimistic and say yes even if there are doubts. They skip feasibility and run into problems in their rush to get to production ASAP. They may keep trying to tackle the inevitable problems that will keep coming up for a while, but eventually, their patience wears thin and they drop the project as they tire of wasting their engineering, sourcing, etc, resources. The problem for you, the customer, in this situation, is that you’ve lost maybe 3-6 months and money on the project and you’re still stuck at square one. That’s a disaster. (16:20)

Common red flags demonstrating that product designs are immature.

There are some common red flags to be aware of that pinpoint that your product design might not be mature enough:

- You only have a sketch on a napkin. So you need to work with an engineer and designer to create CAD designs and firm up your idea. 99% of new product ideas aren’t likely to go anywhere, so manufacturers won’t take a sketch seriously. If a team has worked on it and made something further along in terms of information, aesthetics, understanding of risks, etc, it’s a lot more credible for a potential supplier.

- You have worked with a designer to create beautiful renderings of the product that look great, but there’s no clear path to manufacturing. For example, the resulting prototype has a 3D printed enclosure, but you haven’t considered if it’s possible to injection mold it and it turns out that it isn’t…this means the product design cannot be industrialized and is, therefore, not mature.

- You don’t know how the product works, only how you want it to look. Maybe you’ve done industrial design but skipped the features and information about the product, therefore there is no brief for the manufacturer and they don’t know what key components are or how it’s supposed to work.

- You have selected some parts, but there’s no cohesive plan about how they work together. So you need a structural or mechanical engineer to work on this and devise a way for them to work together.

- You don’t know your buyers. Have you done market research to understand who will use and buy the product? If not, how will you know it is even wanted by the market? Going into production at this point is a huge risk, even if Chinese manufacturers won’t ask you if you have validated the product and done market research.

- You don’t understand your competitive space. You have a product idea, but you haven’t researched the market to see if someone is already making it or at least something very similar. If you have competitors your product will need to be highly differentiated, otherwise, you might be set up for failure right from the start as it’s unlikely you can compete on price with the vast majority of Chinese companies. (18:53)

Summary.

You need to do work on your side – set up a team, have advisors, and get your product concept to a level of maturity before you contact suppliers. Some communities, like the Hardware Academy for electronic products, have plenty of users and experts who can provide advice and support in their forums. (25:41)