All factories are not organized the same way. I have explained this concept to tens (hundreds?) of buyers. It is absolutely fundamental if you want to understand how production works.

All factories are not organized the same way. I have explained this concept to tens (hundreds?) of buyers. It is absolutely fundamental if you want to understand how production works.

Organization in lines

In most Chinese factories that export products to other countries, several operations are performed — often final assembly and packing.

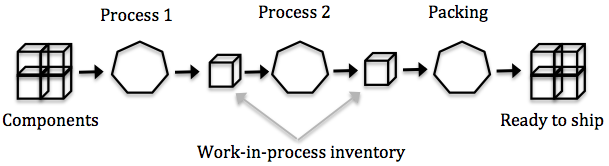

Most people imagine that production is organized this way:

If one line counts 25 workers, and there are 20 lines, there is a total of 500 workers on the production floor.

Consequence of a line organization: the first finished products appear very fast (in less than 2 hours). And corrective actions can be taken early if quality problems are noticed.

Unfortunately, it is seldom that straightforward.

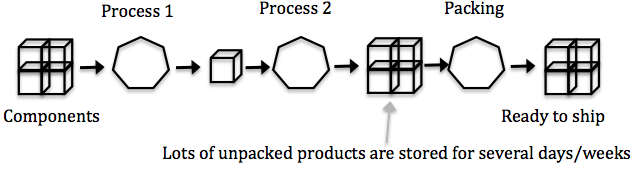

Sometimes we see this: packing is done at the last moment, when nearly all the products are finished.

But still, we can check quality early in the cycle. Not bad at all.

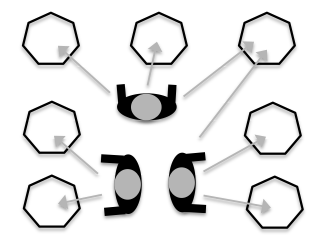

Organization in islands

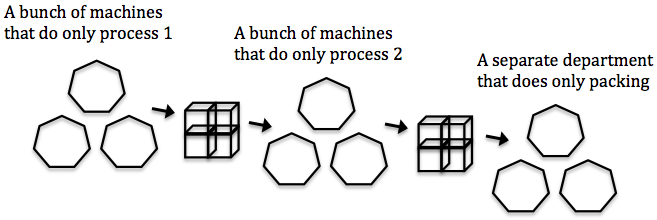

This is the most common type of production organization in China. Most manufacturers here have a batch & queue mentality: “let’s focus on processing huge batches at a time, and we’ll be more efficient”.

So they gather all the similar machines together. One can see an “island” of cutting machines, then an “island” of overlock stitching machines, and so on.

So the first island works on your order for 2 or 3 days, then a second island starts processing your order, and then the third island, etc.

Problems with this type of organization:

- The first finished products appear after 10 or 20 days. Some types of defects can only be noticed at that last stage. And repairing everything can take a long time.

- If a customer asks for production samples, it is usually impossible to send these samples in time (since there are no finished products until late in the cycle), and they end up being made on other machines… Which means they are not representative of the average quality of the order.

- Huge amount of work-in-process inventory that needs to be stored and moved around… And that might get damaged or lost.

- Small orders frequently get lost in the inventory piles.

But the best type of organization is…

Cellular manufacturing

You will probably never see cellular manufacturing in China, except if you visit very advanced factories (in the automobile sector, for example).

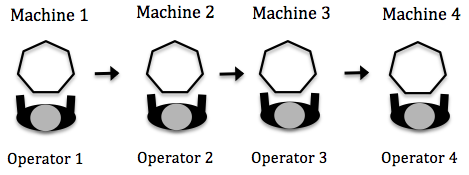

In line organizations, you will see 1 operator on 1 workstation:

In cells, the machines are often arranged in a U shape, and 1 operator can perform several functions:

Advantages:

- The job is less repetitive, and operators keep learning new things. Consequences: improved morale, lower turnover rate.

- The work-in-process products are very easy to reach by each operator. Less wasted time to carry stuff around.

- Each operator adapts the content of his work to create a balance between the needs of downstream and upstream processes (less inventory, better flow).

Challenges:

- Cross training of operators becomes necessary.

- Knowledge and authority shift inside the small team when this structure is adopted. Current leaders will resist it.

- Operators need to use their brains and change their organization often.

Is it clear? What do you think?

Thanks for your article Renaud.

One question : you are saying that “customer could ask for production sample”. Is this really possible? I doubt that the factory would stop everything after spending a lot of time preparing the line.

What do you think?

Or maybe you are talking about the “gold sample” / “pre production” sample…

“Buyers often ask for “production samples”, or “shipment samples”, to have an idea of what finished products look like. But sometimes the finished products appear very late, So what does the factory do, to send these samples in time? It often “prepares” them individually. As a result, these products are not representative of production”

I meant the first finished products, out of bulk production. As soon as these first samples come out, the factory sends them to the customer.

As you correctly point out, very often they appear very late. So the factory prepares them outside of bulk production. It is a joke.

thank you thank you thank you so much Renaud for this article!!! it was a great help!

Thanks for the nice comment!