In the previous article, we mentioned that there should be a Stage Gate Review meeting between each of the development phases. Here in part 3 of the series, we will look at the guidelines for these Stage Gate Reviews. (Don’t forget that you can see the whole series on developing a new product here).

In the previous article, we mentioned that there should be a Stage Gate Review meeting between each of the development phases. Here in part 3 of the series, we will look at the guidelines for these Stage Gate Reviews. (Don’t forget that you can see the whole series on developing a new product here).

What is a Stage Gate Review Meeting

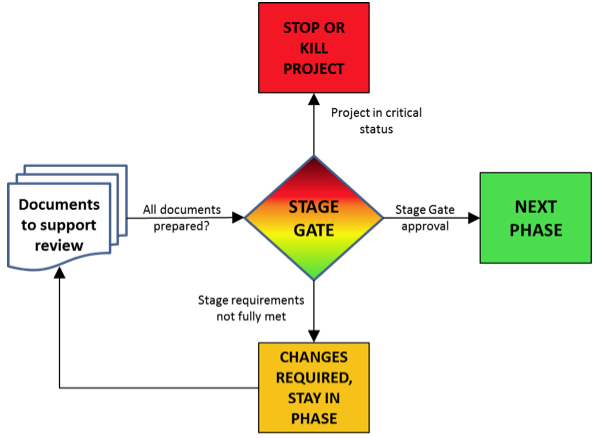

This review meeting is commonly referred to as the Gate which acts as a stop/go virtual barrier between phases. These gates serve as quality control checkpoints on all of the information and data generated throughout the preceding development phase.

There is a structure that should be followed during these gate reviews and it is important to follow a structure. Without a structure and the discipline to follow a structure, the gate part of the stage gate process becomes the weakest part of the process and inevitably poor decisions are made or projects are allowed to move onto the next phase that in truth should either be killed off or reverted back through the preceding phase for additional work.

It has been stated a number of times that this process should act as a funnel and not a tunnel and it is the gates that do the filtering and funnelling.

The Gate Structure

The structure of each of the Gates is similar throughout the whole process so we will just show a guideline to the basic structure.

Deliverables

The deliverables are a set of pre-determined criteria that need to be delivered for review during the gate review meeting; these deliverables should include documentation, data, in some cases physical samples and models. All deliverables regardless of what shape or form they are in should be relevant to the preceding phase and this is what is reviewed during the gate meetings.

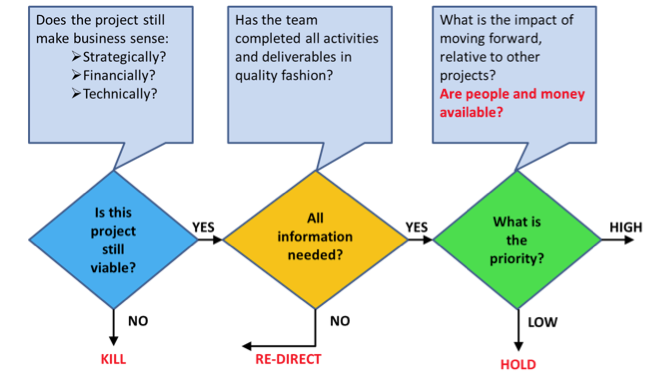

Criteria

Criteria against which the project is judged, this includes different levels from the ‘must meet’ to the ‘should meet’ down to the ‘ideal to have at this stage’. Each gate should have its own checklist and this is where the process is unique as every product will have its own unique set of features and attributes that need to be met.

Output

The output is ultimately the stop or go decision for the project. This can obviously include ‘put on hold’ and the ‘revert back the preceding phase’ which allows further work to be carried out in order for the project to be resubmitted to the review gate.

If the project gets the ‘go’ the project can then move into the next development phase and part of the output would be a plan to shows company financial support and commitment, which include resources, timescales for the next phase and the set of deliverables that must be met during the next phase and which will be used at the next gate review to judge the project against.

The Gate in Graphical Form

Gate Decision Elements

Who Should Attend the Gate Review Meeting

Gatekeepers

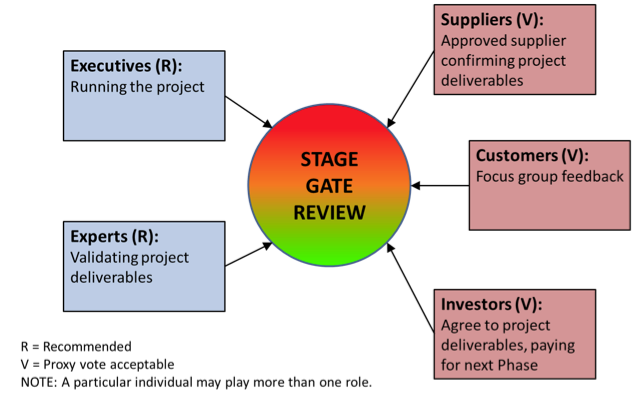

At each of the gate reviews there should be key personnel as shown above, but collectively they are known as the ‘gatekeepers’.

Gatekeeper RULES of ORDER need to be established and enforced (by review meeting chairman). These rules are shown below:

- Gatekeepers must attend in-person or virtually, or your vote defaults to “CONTINUE”. A proxy vote may be designated.

- Gatekeepers must review the team presentation before the meeting.

- Serious concerns must be communicated to teams before the meeting. No “surprise attacks” allowed.

- No “cross-examination” allowed during team presentations.

- Gatekeepers cannot require and/or base decisions on information outside of the scope of the stage being reviewed.

- Decisions must be made in accordance with the criteria for the gate, not on the gatekeeper’s opinions.

- A final vote must be unanimous. Gatekeepers must be willing to negotiate with other gatekeepers.

- You can “HOLD” a stage or entire project but you can’t “HOLD” a decision.

- “CONTINUE” decision means that money and resources are committed for the next phase.

Go to part 4: Testing the Concept

Are you designing, or developing a new product that will be manufactured in China?

Sofeast has created An Importer’s Guide to New Product Manufacturing in China for entrepreneurs, hardware startups, and SMEs which gives you advance warning about the 3 most common pitfalls that can catch you out, and the best practices that the ‘large companies’ follow that YOU can adopt for a successful project.

It includes:

- The 3 deadly mistakes that will hurt your ability to manufacture a new product in China effectively

- Assessing if you’re China-ready

- How to define an informed strategy and a realistic plan

- How to structure your supply chain on a solid foundation

- How to set the right expectations from the start

- How to get the design and engineering right

Just hit the button below to get your copy (please note, this will direct you to my company Sofeast.com):