A lot of companies that import from China have been forced to revise their approach over the last couple of years.

Many of them are currently in crisis, mainly for the reasons listed below:

Difficulties on a macro level

- Continuously rising costs. For many labor-intensive products (especially softlines), China is less competitive than other Asian countries. Many buyers anticipate further increases in the near future, and are moving a part of their production out of China.

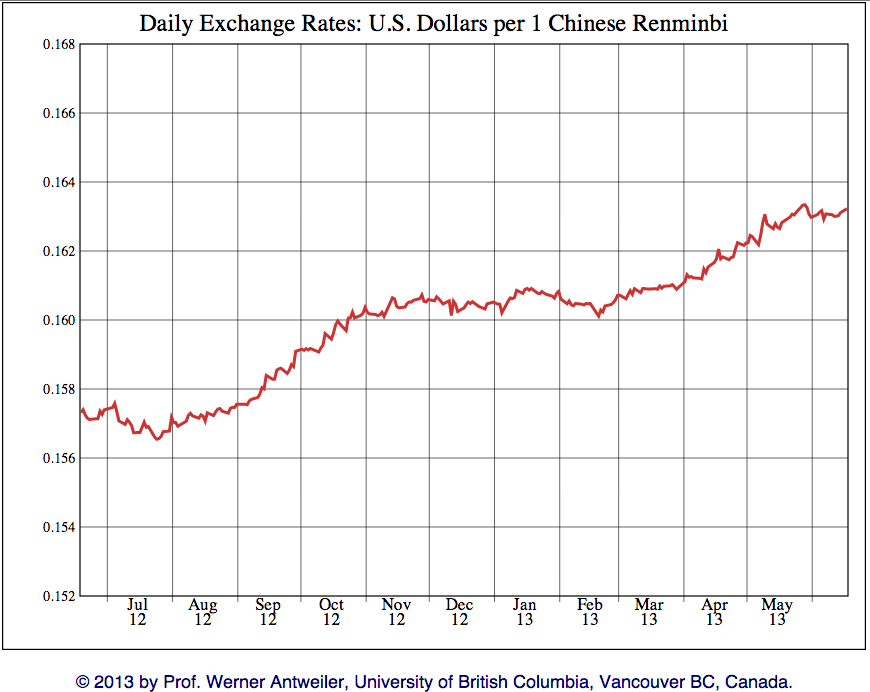

- Appreciating RMB/USD exchange rate (compounded by the fact that suppliers consistently over-evaluate the RMB rise when they price their goods).

- A tightening labor market for blue collar positions, which creates a lack of skilled technicians on the job market.

- A lack of education and training in best-in-class manufacturing practices.

Difficulties on a micro level

- Manufacturers are very slow in improving their organization, and they tend to be short-term focused. They need the constant pressure of quality control monitoring. Few of them are in sync with Beijing’s “move up the value chain” five-year plan.

- Most suppliers truly believe the law is useless, which translates into:

- High danger in sending proprietary designs to several suppliers for quotations.

- Risk that a supplier accepts to sell a customer’s design to another customer, or approaches a customer’s customer directly.

- Risk that a certificate provided by a supplier be fake.

What do you think? Anything to add to this list?

—

PS: if you liked this article, please share it by using the options below. Thanks!

Yep that’s all true. and foreign companies will have the same micro problems (or worse) in any low cost sourcing country (vietnam, pakistan, indonesia).