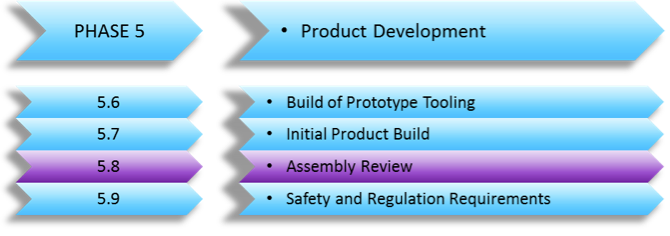

Once a first assembly job has been completed, it is time to review the results. It is not only a matter of checking quality and giving feedback to the Chinese factory as you’ll discover here in phase 5.8.

Once a first assembly job has been completed, it is time to review the results. It is not only a matter of checking quality and giving feedback to the Chinese factory as you’ll discover here in phase 5.8.

(Remember that you can see the whole series on developing a new product here.)

First, what is an assembly line?

It is a manufacturing process in which interchangeable parts are added to a product in a sequential manner to create an end product. In most cases, a manufacturing assembly line is a semi-automated system through which a product moves. At each station along the line, some part of the production process takes place. The workers and machinery used to produce the item are stationary along the line and the product moves through the cycle, from start to finish.

The assembly review is an important activity within the overall review process. Two elements should be considered:

1. Physical product assembly process and techniques from a design perspective

This review should highlight any problem areas during the assembly process so that they can be listed within some sort of register, such as a risk register/improvement plan.

The review should include monitoring areas such as how parts or sub-assemblies are presented to the operators on the assembly line, how many times the operator needs to handle the part before passing onto the next station. Is the assembly in one direction or does the operator need to turn the assembly multiple times in order to complete the tasks?

Other aspects to consider during the assembly review are workstation ergonomics and the ease with which the operators carry out the tasks required at each station, bearing in mind that some may require higher working surface levels than others.

The outcome of this review should be to identify all areas within the assembly that are problematic from a handling point of view, assembly point of view, how long it takes to assemble each particular element, etc. Once a list of all the issues has been identified, they need to be recorded in a process improvement plan. This way a resource can be assigned to generate a corrective action plan for each of the highlighted points.

2. Assembly line flow process review

This will depend on how the manufacturer is structured from a plant processing point of view. I wrote about the differences between the different levels of Chinese factories here.

The outcome of a production line review should be to identify smooth flowing areas and stations, as well as areas where there seem to be hold-ups or looks as if there could be improvements made within the process, taking into account the ease of assembly throughout the flow.

The same principle applies with any areas that were identified as potential candidates for improvement — they should be recorded in a master document.

The second assembly review can also be reviewed with respect to lean production. You can read more on this topic here.

(By the way, I wrote about a good way of managing assembly operations, in case you are still looking for the right setup.)

Go to part 14: Safety and Regulation Requirements china

Want to learn more about the new product introduction process for hardware startups?

Whether you’re some way along the process, or just starting out, Sofeast’s guide covers everything hardware startups need to know for making a new product in China and successfully bringing it to market.

Hit the button below to read the guide: