I usually can’t show photos of the work we do since we are bound to confidentiality. But I have taken a few photos outside of work that I like.

I usually can’t show photos of the work we do since we are bound to confidentiality. But I have taken a few photos outside of work that I like.

Guideline #1: Inspect Each Point Only Once

It seems crazy to us, but the plane and the airport are two links in the same supply chain. That’s what buyers do when they send their inspectors to a factory…

Guideline #2: Defects Might Be Hidden — Plan for That

I have seen several taxi drivers in China driving with their seat belt on… but not fastened!

Some players might circumvent the rules…

Guideline #3: Make the Inspection Process as Visual as Possible

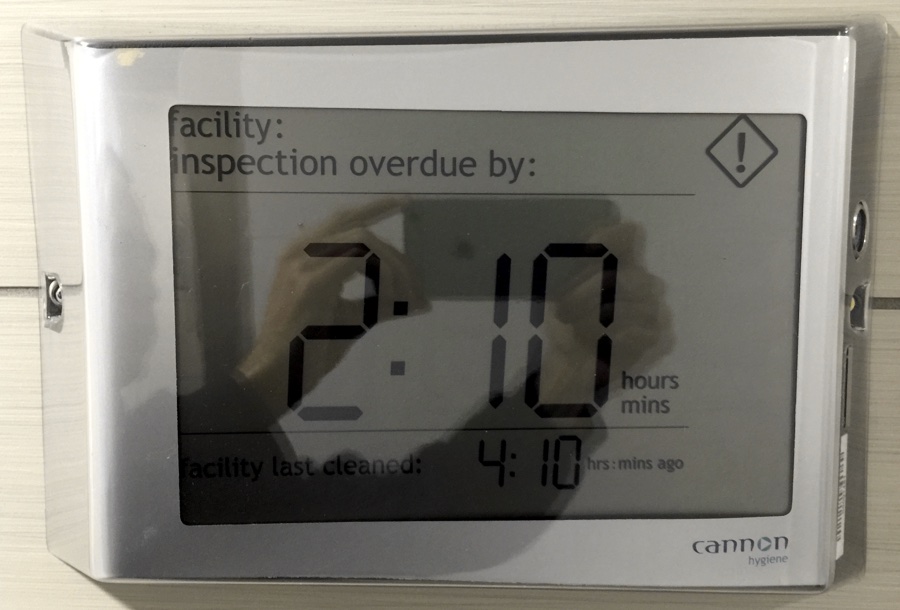

Here is how Auckland airport keeps track of cleaning frequency in washrooms.

This is another good example. Abnormal conditions are easy to detect.

Guideline #4: Work on Reducing the Need for Inspection

I wish more factories had this type of poster on their walls… And actually believed in this message!

Anything to add?