Quality Fade is an insidious practice where the supplier reduces your product quality over time almost imperceptibly in order to cut costs and make more profit. We can all agree that being supplied with products that don't reach our quality … [Read more...]

Improving Product Quality, Reliability, and Compliance with a QA Program

What would a QA program that you put in place to improve the quality, reliability, and compliance of new electro-mechanical products ideally include? Find out here! Prefer listening to reading? Listen to the audio … [Read more...]

Product Quality Strategies: 13 You Need To Use

We've outlined 13 product quality strategies you need to use to achieve consistent product quality, divided into pre and post-production categories, and provide a brief introduction to each here. Prefer listening to … [Read more...]

Evaluating And Validating A Supplier’s Quality The Right Way

Let's look at how a supplier's quality can be evaluated and validated so you know that they will supply you with parts and products that meet your expectations. … [Read more...]

Why the AQL Inspection System Is Still So Widespread

In the 1930s, some smart statisticians at Bell Labs worked on an amazing amount of manual calculations to suggest sampling plans for product quality inspections. Over time, it became the topic of MIL STD standards and one of those plans … [Read more...]

6 Tips To Combat Common Recurring Quality Issues From Your Supplier

What happens if your supplier keeps manufacturing products with various defects, even though you have a quality standard that outlines your expectations? This tends to happen for the same reasons, so here are 6 tips to help you avoid … [Read more...]

What Drives Product Inspection Costs?

It's important to inspect product quality, but if the inspections you get done aren't optimized you could end up spending too much on high product inspection costs which is a problem when that money could be used for other activities. … [Read more...]

The Concept of Quality: Little q VS Big Q.

Take a deep dive into the concept of quality. A lot of importers focus narrowly on if the products they're getting from their manufacturers/suppliers are within tolerance (little q). But without a wider view that looks at the entire … [Read more...]

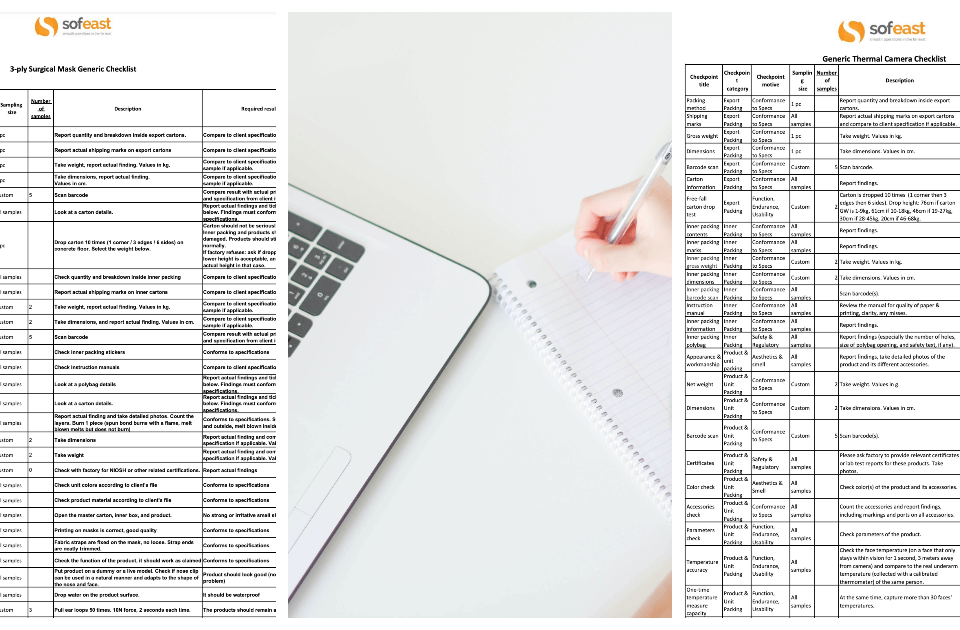

Quality Checklists: 3 Examples for Inspections

Over the years, we have provided feedback to many clients on their product specification sheets and their quality checklists for inspections. Rather than a step-by-step guideline, the most useful is usually to provide them … [Read more...]

Using the Limiting Quality Level (ISO 2859-2:2020) Instead of AQL

A reader asked me how he should do an inspection of a lot produced in isolation. In theory, he should work with the Limiting Quality Level (LQ), not the AQL, which is designed for inspections of a continuous stream of production. I shot … [Read more...]

- 1

- 2

- 3

- …

- 33

- Next Page »