Over the years, we have provided feedback to many clients on their product specification sheets and their quality checklists for inspections.

Rather than a step-by-step guideline, the most useful is usually to provide them with a few real examples for different types of products.

3 examples of quality inspection checklists

In 2020, when personal protective equipment was severely lacking in many countries, we released some of our templates on our commercial website.

I believe they are good starting points to understand what typically goes into one of these documents, how they are structured, and what level of detail is necessary.

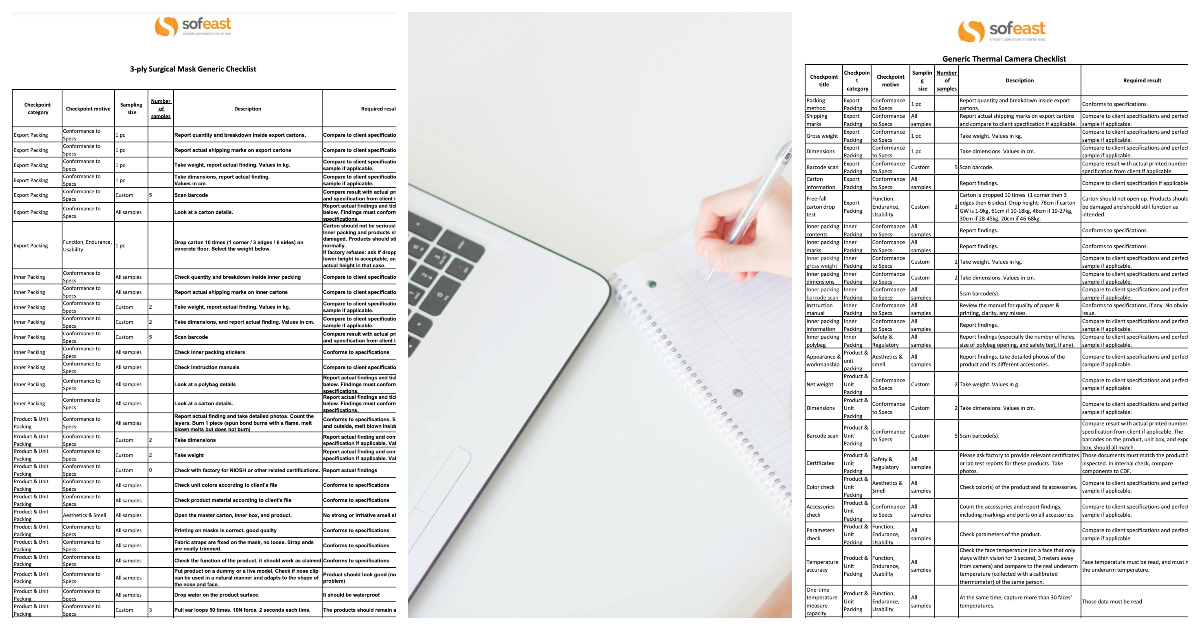

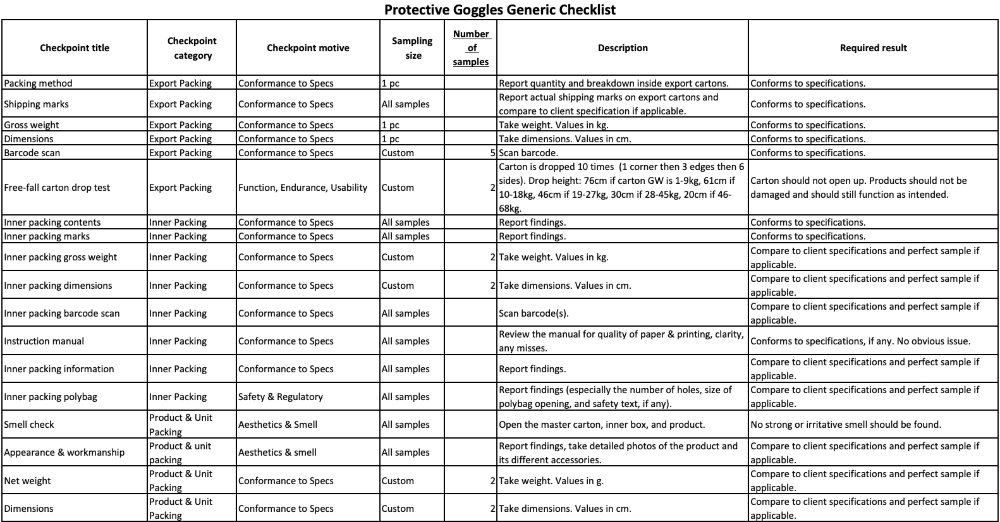

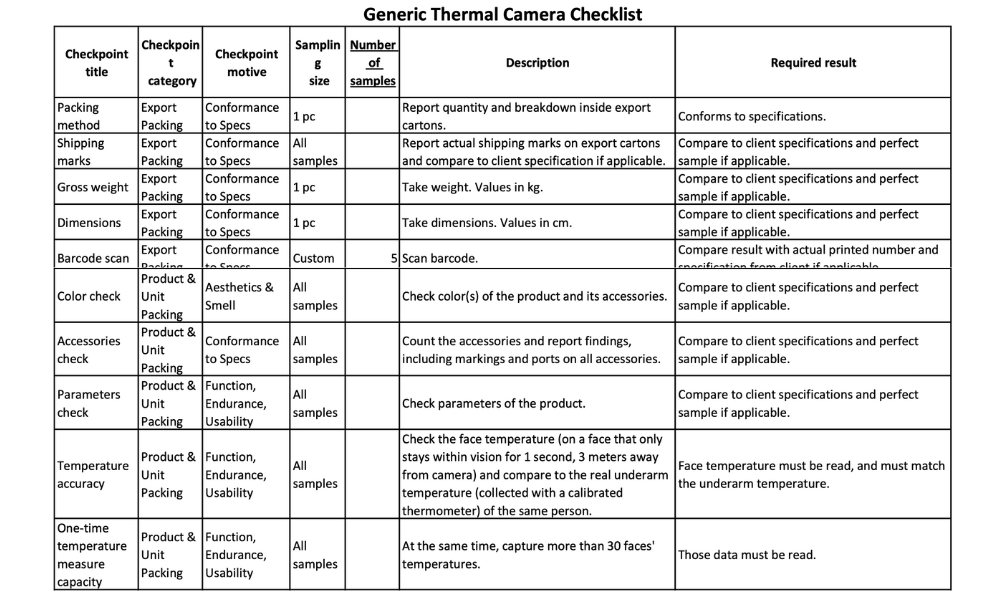

Take a look at the three example quality checklists below (click to expand the image), and please note that there are checkpoints for both the packaging and the product.

- Example for soft goods (3-ply face masks)

- Example for hard goods (protective goggles)

- Example for electronic products (thermal camera)

How to organize a QC inspection checklist

First, you have to think of the best way to guide an inspector through the job. For consumer goods, it generally involves:

- Picking cartons and checking those export boxes (as well as pallets etc.)

- Checking inner packing (be it carton boxes, polybags…), if any

- Checking the products and their unit packing

Then, at each stage, you need to think, about what to check.

- Were specific requirements given to the supplier? Go through those requirements that are really important.

- Any safety or regulatory considerations? Definitely cover them.

- Are aesthetics important? Define what to look at and what common issues are to be counted as defects.

- Any function test, endurance tests, or any similar?

Once you know what needs to be checked, the most important questions are:

- How to check this criterion, and what will consider a pass or a fail?

- How many samples should I check for this point? (Some checkpoints take a long time and/or destroy samples, so smaller sampling sizes may make sense.)

- What measuring/testing equipment will be necessary? Will the inspector bring it, or will the factory have to provide it?

A good checklist is central to managing quality

Managing your suppliers’ quality is a bit like coaching a professional sports team. A big part of the job is about repeating the same thing over and over, to get the basics right.

If you buy a product from a factory located thousands of miles away and rooted in a different culture, you really need to focus on the basics:

- Document your requirements

- Make your requirements s specific and testable, so that they are ready to be used as an inspection checklist

- Ensure your supplier, and especially the people who really count (their purchaser, their manufacturing staff, their quality staff), is aware of your requirements and commits to hitting them

- Inspect products based on your checklist, and request rework/reproduction if needed

Is having a well-documented quality checklist sufficient?

Not always. It depends on your needs.

If you buy some cheap giveaway products, a golden sample and a simple checklist will be great.

If you buy a medical device or automotive accessory, you will need much more.

In The 5 Levels of Quality Standards: From Worst to Best Practices I listed 5 ways to document your standard:

- A golden sample

- A product specification sheet (which is, ideally, in the form of a checklist) + a list of common defects (more on this below) + the bill of materials

- A defect board at the factory, with real physical defective products

- Boundary samples, to show the limit between “acceptable” and “not acceptable”

- To go further, confirming the inspection system and ensuring the ways to measure quality are aligned between the customer and the supplier

What does a list of common defects look like?

When it comes to dimensions, you can set tolerances.

When it comes to function, you can define what is expected – for example, “press the on button and the white LED will turn on”. It is either OK or NOT OK.

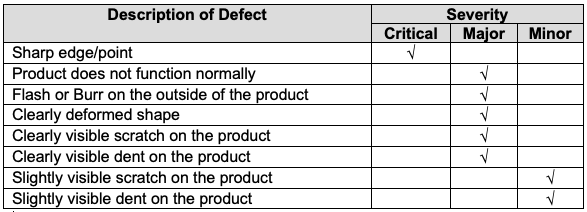

Unfortunately, many other issues may appear in a production batch, and your checklist may not offer a clear way to classify them as defects. For example, a scratch may be slightly visible, or clearly visible. It may be located in a very visible area of the product, or it may be in a place users won’t look at.

Many companies keep a simpler defect list that might look like this:

But, over time, you will probably need to add more and more details, to remove subjectivity from the inspector’s decision. Photos, as you can see below, can often help a lot.

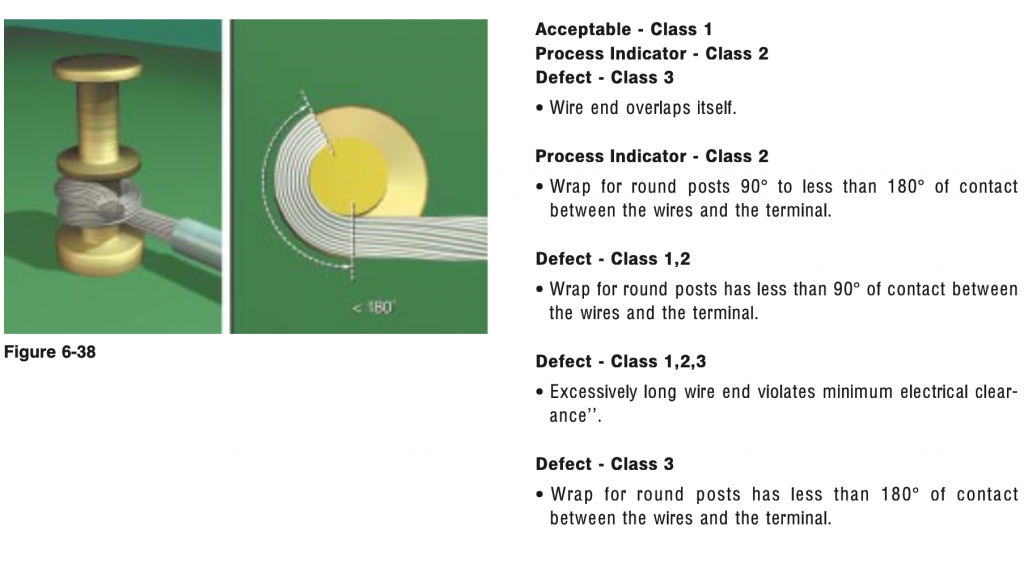

In some cases, the description of the defects needs to be done in excruciating detail. For example, look at the IPC-A-610G standard (about electronic assemblies).

Here is an example (from an earlier post I wrote) of just one type of defect that can be found on a PCBA:

As you can see, this is documented in quite some detail and this makes it easy for all involved to understand what type of defect they may have encountered and see what the issue might look like and where it is in the image provided.

Who usually prepares quality checklists, and at what stage?

To simplify, there are two cases.

- a) You work with a good manufacturer that has a mature quality system

A good manufacturer will NEVER go into mass production without an approved quality checklist. They will NOT accept a high level of ambiguity that may allow a customer to be unreasonable and reject a production batch.

Those manufacturers will create a checklist (or will adjust an existing one that was used before on similar products) and will require the customer to sign off on it.

- b) You work with an immature manufacturer, and you cannot count on them

In that case, you are on your own… You need to do it yourself or hire a quality assurance agency (like ours, among others) to create it for you.

Again, as noted earlier, it is not always a must. If you are happy with a golden sample and a few simple instructions, and you place small orders of a simple product, that might be all you need.

More reading & listening on the topic of quality checklists and standards

- More advice on setting up a good checklist

- How to prepare a QC inspection checklist [infographic]

- What Are Quality Standards? [Podcast]

Editor’s note: This post was originally published in April 2021, and has been updated with new content in October 2022.

Quality Assurance Policy For Importers In China [Webinar]

What is the 80/20 rule when it comes to QC in China? The answer is building a strong quality assurance policy of your own.

In this webinar, we’re going to explore key challenges facing importers from China, and the elements that compose a really solid, effective quality assurance policy.

Improving your quality assurance will help avoid poor quality products from hurting your business. Hit the button below to register to watch the webinar!