We have worked with many companies that buy products from China & Vietnam, and their most common shortcoming is probably the lack of a clear quality standard. They don’t document what they are willing to accept.

They start working with a new manufacturer and both parties often get confused about what is acceptable.

Now, people often ask us what a quality standard that goes into the details looks like. We can’t share any examples from our clients, for confidentiality reasons. Fortunately, there are plenty of publicly available examples.

Let’s look at the IPC-A-610G standard (a great guide for inspectors who check finished PCBAs).

1. Distinguishing several categories/classes of products

The buying organization is encouraged to classify its products into 3 classes:

CLASS 1 – General Electronic Products

Includes products suitable for applications where the major requirement is function of the completed assembly. Least expensive manufacturing cost. (Toys.)

CLASS 2 – Dedicated Service Electronic Products

Includes products where continued performance and extended life is required, and for which uninterrupted service is desired but not critical. Typically, the end-use environment would not cause failures. Nominal expensive manufacturing cost. (Computers & Phones.)

CLASS 3 – High Performance Electronic Products

Includes products where continued high performance or performance-on-demand is critical, equipment downtime cannot be tolerated, end-use environment may be uncommonly harsh, and the equipment must function when required, such as life support or other critical systems. Most expensive manufacturing cost. (Military & Medical.)

(Note: in many quality standards, the emphasis for aesthetic effect is on the surfaces of the product: surface A is most visible, surface B is not very visible, surface C is usually not visible.)

2. Defining several levels of acceptance

They define 4 levels of acceptance in this standard.

Target Condition A condition that is close to perfect/preferred, however, it is a desirable condition and not always achievable and may not be necessary to ensure reliability of the assembly in its service environment.

Acceptable Condition This characteristic indicates a condition that, while not necessarily perfect, will maintain the integrity and reliability of the assembly in its service environment.

Defect Condition A defect is a condition that may be insufficient to ensure the form, fit or function of the assembly in its end use environment. Defect conditions need to be dispositioned by the manufacturer based on design, service, and customer requirements. Disposition may be to rework, repair, scrap, or use as is. Repair or ‘‘use as is’’ may require customer concurrence.

Process Indicator Condition A process indicator is a condition (not a defect) which identifies a characteristic that does not affect the form, fit or function of a product.

(Note: for many consumer goods, it is typically “no defect”, “minor defect”, “major defect”, and “critical defect”.)

3. Providing a list of common defects

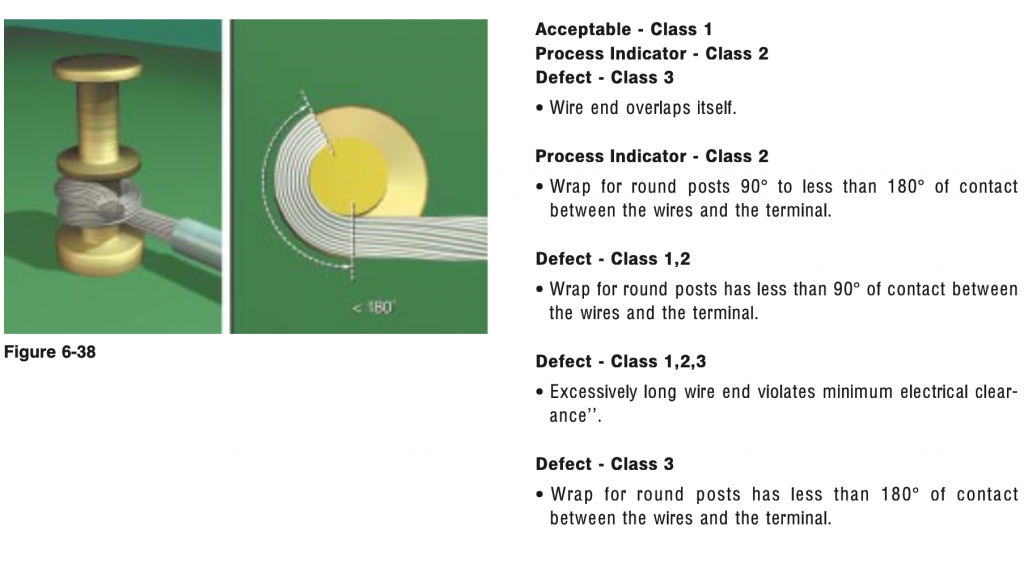

The standard goes on for more than 400 pages with all the most common defect types that can be found on PCBAs. Here is one example.

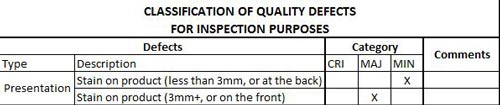

(This is very nice documentation. At a more simple level, most of our clients work on a simple list as below, and over time they add entries as well as representative photos.)

With a bit of research, drawing an initial list of potential issues is often easy. For example, we provided some examples before (common defects from processes such as plastic injection molding, welding, die casting, and common mechanical defects in general).

After a year of continuous logging of the issues you detect, you should have a pretty nice list of candidates!

Further reading about the quality standard topic:

Sofeast: Quality Assurance In China Or Vietnam For Beginners [eBook]

This free eBook shows importers who are new to outsourcing production to China or Vietnam the five key foundations of a proven Quality Assurance strategy, and also shows you some common traps that importers fall into and how to avoid or overcome them in order to get the best possible production results.

Ready to get your copy? Hit the button below:

Helpfully is a great cost effective resource that can assist businesses looking to raise finance as a start up