China used to be well-known for mainly cheap, low-quality products, but those days are largely behind us. Any number of cutting-edge and high-quality products are made in China now, think Apple and Tesla products, world-class white goods, … [Read more...]

What are Boeing’s Bad Manufacturing Habits Leading to Quality and Reliability Risks?

Boeing has not been far from controversy in recent years, with highly publicised 737 Max air crashes about 5 years ago and, more recently, a near-disaster on a brand new Alaska Airlines Max which suffered a mid-air door plug blowout putting … [Read more...]

Product Quality Strategies: 13 You Need To Use

We've outlined 13 product quality strategies you need to use to achieve consistent product quality, divided into pre and post-production categories, and provide a brief introduction to each here. Prefer listening to … [Read more...]

6 Tips To Combat Common Recurring Quality Issues From Your Supplier

What happens if your supplier keeps manufacturing products with various defects, even though you have a quality standard that outlines your expectations? This tends to happen for the same reasons, so here are 6 tips to help you avoid … [Read more...]

Pay me now, or pay me later: Your choice when it comes to product quality and reliability.

What is the real cost of poor product quality and reliability and what can be done to lower your risks and costs? You'll learn why the phrase “Pay Me Now, or Pay Me Later" is particularly relevant because the costs of good quality and … [Read more...]

The Concept of Quality: Little q VS Big Q.

Take a deep dive into the concept of quality. A lot of importers focus narrowly on if the products they're getting from their manufacturers/suppliers are within tolerance (little q). But without a wider view that looks at the entire … [Read more...]

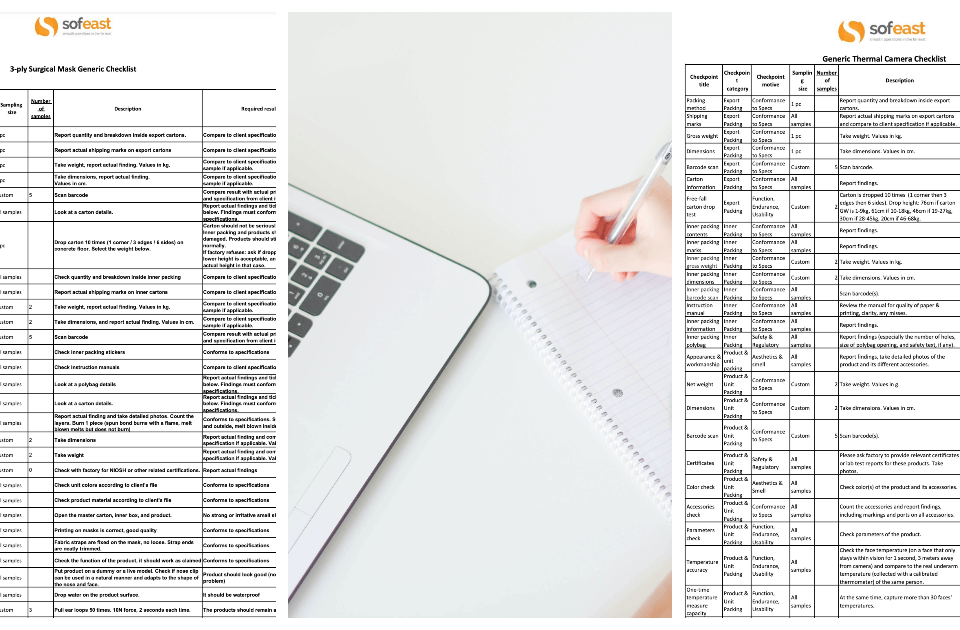

Quality Checklists: 3 Examples for Inspections

Over the years, we have provided feedback to many clients on their product specification sheets and their quality checklists for inspections. Rather than a step-by-step guideline, the most useful is usually to provide them … [Read more...]

Fixing Product Quality Issues: MFG vs. Product Design Causes

About two or three times a month, a client tells us about serious issues they have experienced with a certain product, and they ask if we can help fix those product quality issues. In some cases, it is relatively quick and easy. In others, … [Read more...]

Planning for Quality & Compliance at the Product Design Stage: 3 Topics You MUST Focus On

A reader asked what he should pay attention to when he starts to work on a new product in order to avoid a very large “dumb tax” in the future. This is a good question, as there are many activities to undertake that will help your … [Read more...]

Basics of Supplier Quality Management: A Good Training & Book

From time to time, I skim through a book or training that covers a topic to see if there is a new angle that we might benefit from. This time, I picked the training entitled Seven Essentials in Supplier Quality Management by Evelyn Tan, … [Read more...]

- 1

- 2

- 3

- 4

- Next Page »