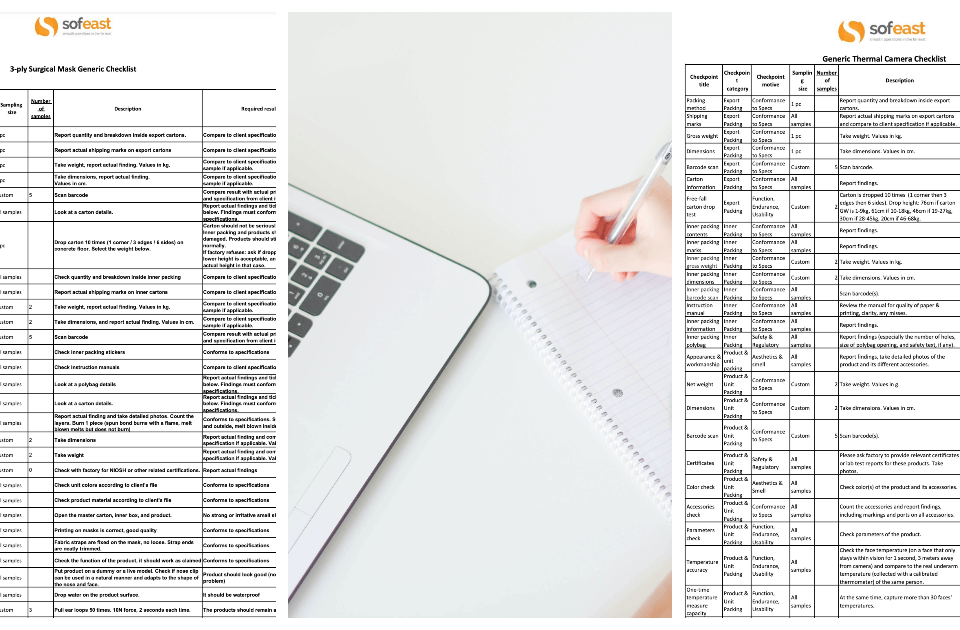

Over the years, we have provided feedback to many clients on their product specification sheets and their quality checklists for inspections. Rather than a step-by-step guideline, the most useful is usually to provide them … [Read more...]

What To Do If Your Products Fail An Inspection? [Step-By-Step Process]

Sofeast's CEO Renaud Anjoran and Adrian from the team are back and talking about something else you don't want to experience but may if you're unfortunate. A failed product inspection! Renaud will explain to you why the type of … [Read more...]

What is a Receiving Quality Inspection, and How to Set Yours Up? [Podcast]

In this episode… How do you assure that the parts and materials (inputs) your manufacturer receives from their sub-suppliers are good quality and won't lead to defective finished products? You perform a receiving quality inspection on … [Read more...]

Sourcing from China (Part 3): Project management & checking quality early in production. [Podcast]

In this episode… We continue to explore what importers who're new to outsourcing manufacturing to suppliers in China need to be able to handle themselves when sourcing, developing products, and manufacturing there. In part 2 of the … [Read more...]

Harsh Realities of Managing a Quality Control Team in China

A few years ago, I suggested 6 tips to avoid bribery in a QC team. And two of them are particularly important when managing a quality control team in China: Rotate inspectors among factories, as professional relationships very quickly … [Read more...]

Tips For Buyers On A Budget Who Want To Start Manufacturing In China [Podcast]

In this episode... You'll love this episode as it contains loads of helpful tips for buyers from China who're operating on a smaller budget from Sofeast's CEO Renaud and this week's guest, sourcing expert, Rico Ngoma from Source Find … [Read more...]

Inspecting Product Quality: What Are Your Options?

If you purchase products from an overseas supplier that you don't know well, and you can't be there, you might want to contact an inspection agency to handle inspecting product quality on your behalf. But you need to give them direction … [Read more...]

Understanding Product QC Inspections: What Is In A Man-Day?

A conversation earlier today made me realize that some buyers who haven’t spent much time in Chinese factories have some common misconceptions, including inaccuracies about a QC inspector's man-day, or stories like: “Chinese production … [Read more...]

From Data Science To Machine Learning in Manufacturing, for Smarter Quality Control

I have long been put off by all the hype around artificial intelligence (AI). AI has become the modern 'magic wand': nobody knows how it works, but the results are assuredly amazing. AI has limitations for manufacturers, but both data … [Read more...]

Traceability in Manufacturing: Do your Chinese Suppliers Do it Right?

I see buyers who spend a lot of time pushing their suppliers to do QC inspections on incoming components, to keep the production area clean, to give clear instructions to operators, and other basics. But I seldom hear them push for … [Read more...]

![What To Do If Your Products Fail An Inspection? [Step-By-Step Process]](https://qualityinspection.org/wp-content/uploads/2022/09/WhatToDoIfYourProductsFailAnInspectionStep-By-StepProcess-960x630.jpeg)

![What is a Receiving Quality Inspection, and How to Set Yours Up? [Podcast]](https://qualityinspection.org/wp-content/uploads/2022/04/WhatisaReceivingQualityInspectionandHowtoSetYoursUpPodcast-960x627.jpeg)

![Sourcing from China (Part 3): Project management & checking quality early in production. [Podcast]](https://qualityinspection.org/wp-content/uploads/2021/12/SourcingfromChinaPart3Projectmanagementcheckingqualityearlyinproduction.Podcast-960x627.jpg)

![Tips For Buyers On A Budget Who Want To Start Manufacturing In China [Podcast]](https://qualityinspection.org/wp-content/uploads/2021/07/TipsForBuyersOnABudgetWhoWantToStartManufacturingInChinaPodcast-960x627.jpeg)