Angel Ho, CEO of Hongda Business Services in Shenzhen, gives us a view from on the ground in China today about what the business environment for foreigners seeking to do business there is really like right now. She also explains the process … [Read more...]

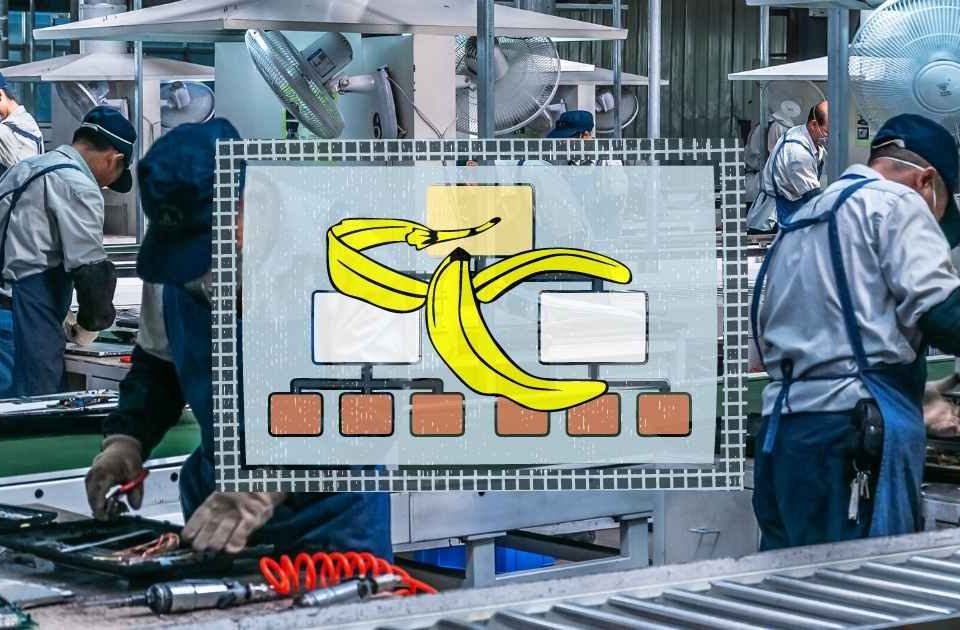

Manufacturing Organizational Chart: Top 7 Common Mistakes To Avoid

One of the first things we look at, during factory audits, is the supplier’s manufacturing organizational chart. And it often points to serious operational dysfunctions. Here are the top 7 common mistakes that you don’t want to see your … [Read more...]

Want To Prevent Assembly Problems? Use This Checklist.

Pilots follow a checklist before they fly. Same thing for doctors & nurses. But, for some reason, I see very few Chinese factories follow a checklist that can help them avoid assembly problems before they make a new product (for the … [Read more...]

Is Investing In Process Automation In The Factory Worth It? + Implementation Best Practices [Podcast]

Automation is a major focus of the Chinese government and many manufacturers here, but can it really reduce costs..? Renaud will answer the questions: "Is Investing In Process Automation In The Factory Worth It?" and "What are the best … [Read more...]

How We Set Up A New Factory In China From Idea To Operation [Podcast]

Planning on opening a factory in China in 2021? To get some insight into just what it takes to set up a new factory in China let's explore how WE came to open our own factory, Agilian Technology, there in 2018! Renaud will explain the … [Read more...]

Factory Management: the 4 Main Roles in the Quality Department

China, as a whole, has 35+ years of experience manufacturing products for export customers. They have accumulated a lot of experience. However, foreign buyers are rather consistently shocked at the level of mismanagement that plagues … [Read more...]

Traceability in Manufacturing: Do your Chinese Suppliers Do it Right?

I see buyers who spend a lot of time pushing their suppliers to do QC inspections on incoming components, to keep the production area clean, to give clear instructions to operators, and other basics. But I seldom hear them push for … [Read more...]

Chinese- vs. Japanese-Owned Factories in the US: Main Differences

A journalist contacted me and inquired about the differences between Chinese-owned factories (a new phenomenon) and Japanese-owned factories in the context of new plants set up in the US. Interesting topic. Not unsurprisingly, Chinese … [Read more...]

![Is Investing In Process Automation In The Factory Worth It? + Implementation Best Practices [Podcast]](https://qualityinspection.org/wp-content/uploads/2021/03/IsInvestingInProcessAutomationInTheFactoryWorthItImplementationBestPracticesPodcast-960x630.jpeg)

![How We Set Up A New Factory In China From Idea To Operation [Podcast]](https://qualityinspection.org/wp-content/uploads/2021/02/HowWeSetUpANewFactoryInChinaFromIdeaToOperationPodcast.jpg)