This is the fifth in the series of articles helping you through the New Product Development process.

This is the fifth in the series of articles helping you through the New Product Development process.

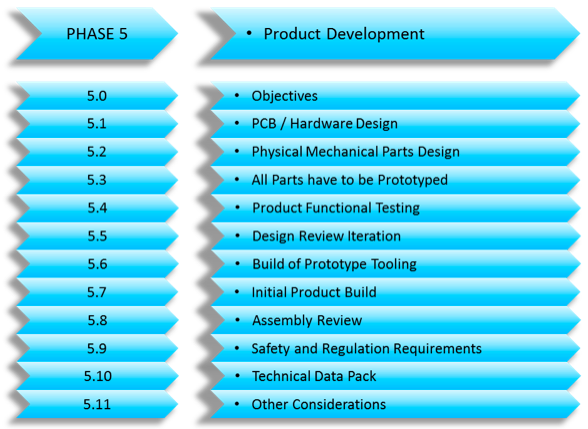

Now we’re moving on to phase 5:

In this post, we’ll briefly go over the objectives of this phase.

During the product development phase, the product is designed, built, tested and finalized ready for mass production. The main tasks in order to achieve this are listed below (obviously this is an example that needs to be adapted to your product):

- PCB / hardware design

- Physical-mechanical parts design

- All parts to have a prototype built

- Product functional testing

- Design review iterations

- Build of pre-production tooling

- Initial product build

- Assembly review

- All safety and regulation requirements testing and approval

- Technical data pack including all engineering drawings and specifications.

- Also included in this phase are the design for the product packaging, user instructions, marketing materials and any other item requiring design input.

Many good articles are coming up soon…

Go to part 6: Developing the PCB for a Product Made in China

Want to learn more about the new product introduction process for hardware startups?

In this guide, we explore everything that inventors, SMEs, and hardware startups need to know about making a new product in China and bringing it to market.

We include:

- Why preparation between product design and launch is necessary

- Exploring the NPI process, from product idea to production

- Finding the right manufacturing partner

- Design reviews & adjustments: DFM, DTC, DFQ

- Optimizations for improving cost and quality

- Small production runs before mass production

- Your role in the NPI process