Last week I pointed out the limits of QC inspections based on random sampling. My conclusion was:

Last week I pointed out the limits of QC inspections based on random sampling. My conclusion was:

If having 3% of defects in a batch can incur very high costs (likely to wipe your margin out and cause a loss in customer confidence), random inspections are NOT appropriate.

So, what is the alternative? Checking 100% of the pieces, one by one?

That’s one solution. But it is can be quite expensive. Let’s say there are 15,000 pieces and an inspector can only check 600 pieces in 1 man-day. That’s 25 man-days of work, or at least 7,000 USD just for quality control!

A quality control plan that optimizes the tradeoff between inspection costs and risks exists. I know of two such solutions.

1. A dynamic inspection plan

This is a good plan if you check products that were made in a large batch.

Here is an example. (Note that I purposefully don’t use statistics for certain parts of this exercise. Feel free to adjust the numbers in a way that makes you comfortable.)

1.1 Inspectors start with a random sample in normal severity, level III. That’s 500 samples.

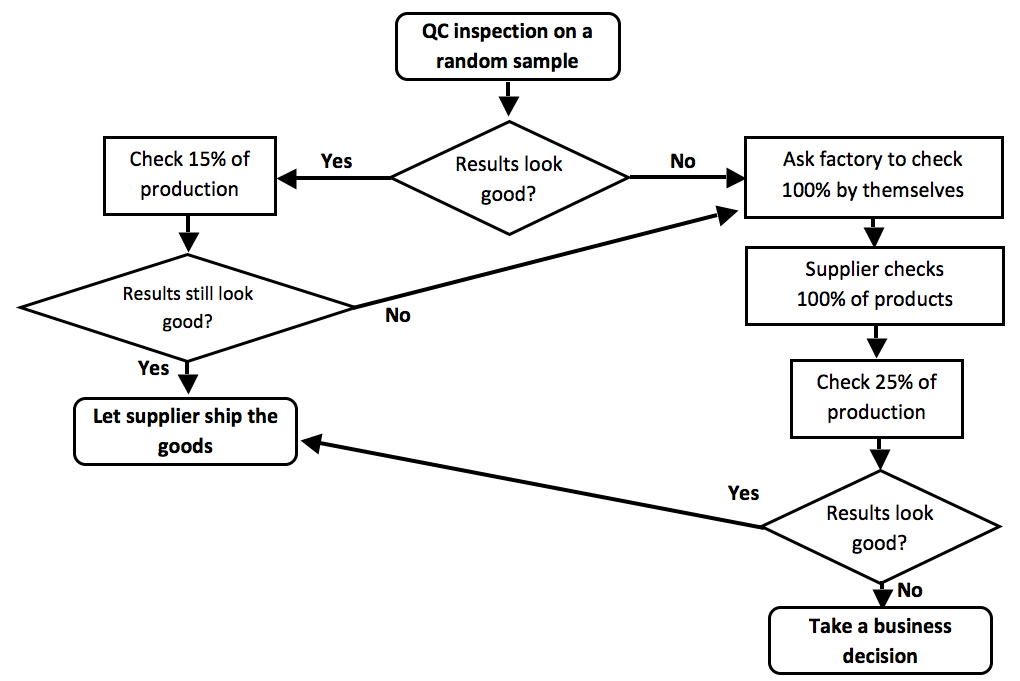

1.2 Based on the findings, there are two options.

1.2.1 If results look good: go for a more in-depth inspection (but not on 100% of the pieces) before taking any decision.

Check 15% of the remaining 14,500 products, but only for the types of defects the client thinks are really dangerous (in a commercial or a safety sense). This way, you may spend only 3 man-days (vs. 25 man-days according to our previous calculation).

If these dangerous defects are below a certain limit (you should set this limit in advance), let the supplier ship out. If not, go for 1.2.2.

1.2.2 If results look bad: ask the manufacturer to check all the remaining goods (except what was already checked) and present the batch again later. Ask them for exact numbers of “good”, “bad but could be reworked”, and “bad but could not be reworked” pieces. It will give you an idea of the seriousness of their self-inspection.

Then, when the batch is presented again, check 25% of the products for the types of defects the client thinks are really dangerous. If these dangerous defects are below a certain limit, let the supplier ship out. If not, go for 1.2.3.

1.2.3 If results look bad after the factory has sorted all the remaining goods, you basically have 3 options:

- If you are not in a hurry, and if the factory seems cooperative: ask them to sort the whole batch again. Put pressure on them, to have a higher proportion of “bad” pieces in their findings than the previous time.

- If you are in a hurry and the factory is not cooperative: pay for a 100% check. If possible, force the supplier to pay for at least part of it.

- If you are in a hurry, if the factory is not cooperative, and if you can’t afford to pay for a 100% check: take a business decision (let the products ship, or cancel the order).

2. Continuous sampling

This is a good plan if you check products that were made one by one, continuously.

“Continuous sampling” is the best plan when products are made individually in a continuous flow.

It consists of several phases:

- At the beginning, each piece is checked (that’s the “screening”).

- After a certain number of pieces were found satisfactory, only certain pieces are checked randomly (that’s the “sampling”).

- If a piece is defective: back to screening.

SQC Online allows us to use a free calculator to get the settings appropriate for such a plan.