A few months ago, I drew a flow chart for buyers to follow when a problem is detected during an in-process inspection.

A few months ago, I drew a flow chart for buyers to follow when a problem is detected during an in-process inspection.

But the very best would be for factory operators themselves to notice defects and to solve the problem immediately, right?

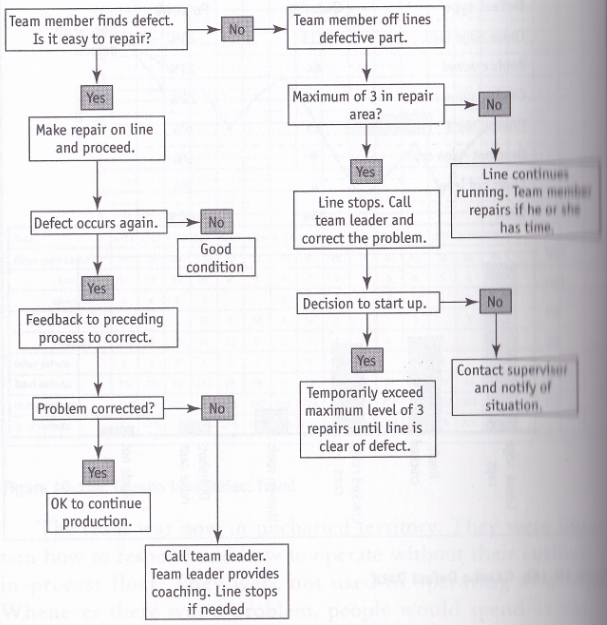

I just found an excellent flow chart that addresses this purpose:

Source: “Cedar Works” case study, Becoming Lean: Inside Stories of U.S. Manufacturers, edited by Jeffrey Liker.

Unfortunately, it only works if line workers are allowed to stop the line when defects are noticed. In the world of exporting manufacturers in China, nobody can even imagine that happening. The priority is to “push production out the door”.

And there is a dedicated final QC section, just before the packing stage. Why would line workers, who are generally paid by the piece, bother with defects coming from an upstream process?