As more and more companies buy products in China and then sell them on Amazon, many of them are finding it hard to control quality.

The problem is, there is a big disconnect.

A relatively low proportion of defective pieces (say 3%), is to be expected for consumer goods made in China. If you get about 3% of “bad” products on every one of your shipments, you are not doing bad.

Most buyers of consumer goods set an AQL at 2.5% for major defects and 4.0% for minor defects. In practice, the tolerance band is actually higher because the underlying standard limits the producer’s risk more than the consumer’s risk.

However, on Amazon, it can be a disaster. It can result in a 20% of “one star” ratings. And disappointed customers are much more likely to complain… which might prevent further sales (the limit is 1% before getting kicked out).

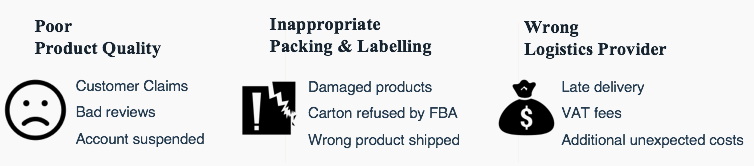

We wrote before about the common problems of Amazon sellers:

How to avoid these issues?

Can you choose a supplier based on a sample, a price, and their marketing budget & skills? And then run standard QC inspections? And have the supplier ship directly to Amazon’s fulfillment centers?

Sometimes it works. But it is quite risky.

Yes you can send an inspector before shipment. But what if he finds serious issues? Do you have time to qualify a new supplier, get production going, and so on? Most buyers in this situation try to do damage control:

- Ask the supplier to sort and rework

- Ask the inspector to come again

- Decide whether to go into another re-work & re-inspect cycle (will the supplier actually do it?) or to let the supplier ship.

The level of danger varies with the product category and with the positioning (are you selling a premium product, or competing on price?), to be sure.

- If you sell packs of cheap accessories that end up being given away, a few defective pieces inside each pack probably won’t result in many complaints.

- If you sell any sort of expensive item and 3% don’t actually work, you can be sure Amazon will notice a lot of returns.

Which means… buyers should take the right steps to ensure product quality more upstream in their purchasing & development process.

—–

This is what I will discuss on April 17 in Hong Kong. Global Sources invited me to speak at this conference:

Global Sources Summit

3-day conference for online & Amazon sellers

April 17-19, 2017

AsiaWorld-Expo, Hong Kong

- Cover China importing & online/Amazon selling-related topics

- Plenty of built-in networking opportunities

- Co-located with trade shows so attendees can put their learning into practice immediately

- 3,000+ booths of gifts, home products & mobile electronics

You can benefit from Super Early Bird Prices if you register now on www.globalsources.com/summit.

Hope to see you there!

—–

Update: here is a nice post from Jacob Yount on the topic of quality inspection for FBA sellers.