Many importers have learned the value of a good supplier pool the hard way.

Many importers have learned the value of a good supplier pool the hard way.

For example, Carrefour Global Sourcing “killed its supplier base” (in the words of their managing director) because they pursued low prices with a reverse auction mechanism. They recently decided to stop it.

As a consequence, they spend millions of dollars in QC inspections that wouldn’t be needed had they kept their supplier pool intact.

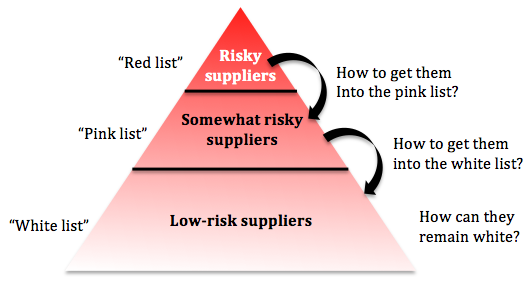

Importers should do the exact opposite. They should distinguish 3 categories of suppliers. Like a portfolio of assets that can be improved:

The question is, how to get more and more suppliers in the white list? This is the key to reducing your QC budget AND your quality problems at the same time.

Here is what I propose.

At the beginning, only the very best suppliers are white. This status is earned by the others, little by little, based on their results. If they fail inspections too often, they never get to be white-listed.

Getting a supplier from red to pink

- Train the factory technicians;

- Help them improve production processes and the quality system (only if they are interested);

- Charge the re-inspections (triggered by the refusal of an inspection) back to them;

- Have a dialogue with the management team and write customized recommendations (including, but not limited to, a corrective action plan).

Getting a supplier from pink to white

- Keep helping them improve the quality system (only if they are interested);

- Train “certified factory-stationed inspectors” and check whether they catch & report quality issues (only if the factory management welcomes this idea);

- Charge the re-inspections (triggered by the refusal of an inspection) back to them;

- Have a dialogue with the management team and write customized recommendations.

Getting a supplier to remain white:

- Spot checks with an element of surprise, to keep a certain level of pressure;

- Audit their quality system at least once a year;

- Ask for more transparency (no undisclosed subcontracting, identification of managers primarily responsible for your orders…).

One last word. Be clear about this process with your suppliers. It will show them that their interest lies in improving their reliability.

What do you think?

———-

Follow-up article: How to develop Chinese suppliers

Related reading: QC inspections are only a part of your quality assurance strategy

I wanted to thank you for this great read!! I definitely enjoying every little bit of it I have you bookmarked to check out new stuff you post

Thanks Anthony! You can subscribe to new update, too (see at the top left of this page).