Let’s say you are an importer, looking for a provider of QC inspection services in China. You will evaluate candidates on how serious they look, on their size, and maybe on their knowledge of your product line, right?

Let’s say you are an importer, looking for a provider of QC inspection services in China. You will evaluate candidates on how serious they look, on their size, and maybe on their knowledge of your product line, right?

Well, you’ll be missing one important question: are they focused on flexibility or on reliability? Inspection firms be both very flexible and very reliable.

I distinguish two types of companies in the industry.

Note: I excluded the largest companies from this analysis, because they are more focused on serving big retailers, and they make most of their money from laboratory tests.

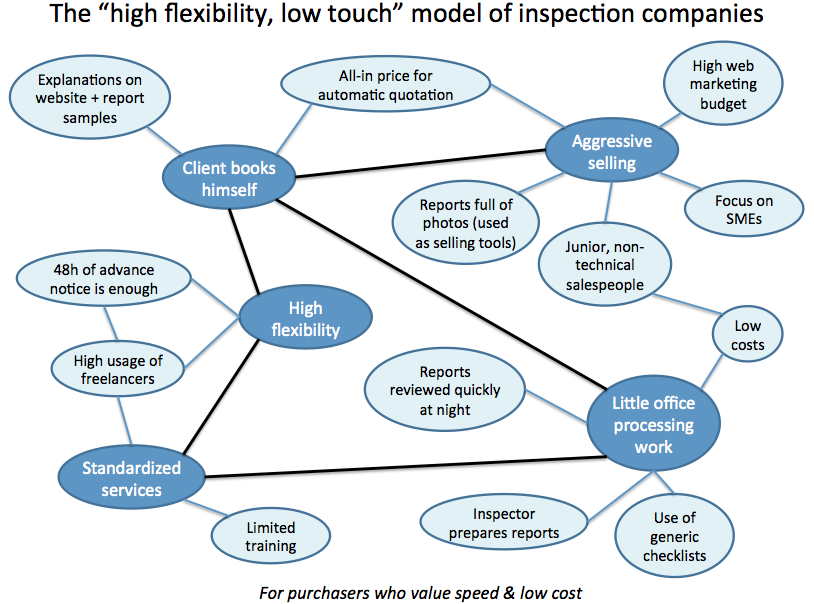

Type A: the “high flexibility, low touch” agency

This model appeared less than ten years ago, but its pioneer has grown extremely fast and has inspired a series of copycats. They are very present on the internet, so you will find them easily via a Google search.

This is a suitable offer for purchasers who:

- Need to be able to book an inspection for the day after tomorrow (and who can’t tolerate a response such as “sorry, all our inspectors are already assigned to jobs, can we do this in 3 days?).

- Work on simple consumer goods, and are happy to get reports with many photos and little text.

- Want to know the inspection cost in advance, in a predictable way.

- Don’t mind booking the inspections by themselves, every time.

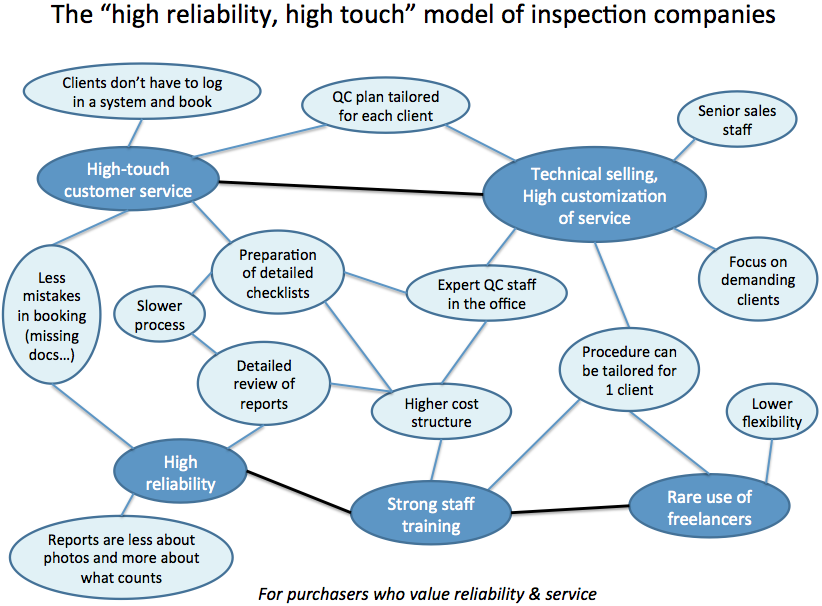

Type B: the “high reliability, high touch” agency

In contrast, some QC agencies follow a very different model.

This is a very good offer for purchasers who:

- Value quality over speed, and who are willing to pay, or to wait, a little more just to be sure that they will receive exactly what they have ordered.

- Work on complex products, or have special requests. They want to work hand in hand with a technician who will come up with a suitable solution.

- Want to work with a partner company (who takes over certain activities in their organization) over the long term. This is not a one-shot deal.

This is what I call hands-on buyers: they tend to work with fewer manufacturers, they often deal with one product category only, and they sell in a channel that won’t accept quality problems.

How to spot whether an inspection firm is type A or type B?

Nobody admits to favor flexibility at the expense of reliability, of course. Everyone claims to employ the most qualified inspectors. It is amazing how a sleek website and a confident sales force can distort a potential client’s perception.

However, since type-A and type-B companies target different importers, their sales pitches focus on different arguments:

- Type A (high flexibility, low touch) firms boast an online booking system, how fast they are, and an all-inclusive price.

- Type B (high reliability, high touch) firms mention their outstanding service and offer a wide range of solutions. They don’t show a price on their website.

All right, now you are warned… You wouldn’t use a Ferrari to go off-road, or a Land Rover for extended highway travel. Don’t make these mistakes when you pick a QC firm.

———————-

Note: these mappings are inspired by the illustrations of the “What Is Strategy?” article, by Michael Porter.

an excellent analysis of the typee of QC firms in operations and practice. Every business firm takes shape as shaped by the market forces. In a market economy where the price decides the demands rate the flexible firms makes the best of business. After all inspection as a function and profession is unique and same in principle either it is for the castings of an engine or the turbine or the gnerator so far it is the castings. the inspectors job is to study and understand the requirments as spelt out by the client and confirm that the inspected product the casting meets the specified needs in terms of stabiility of measured characteritics through the systems of specified tests and measurments methods. So knowledge of casting and measurments is critical but not necessarily the domain knowledge which is taken care of by the designer of the product.So the inspector generates a report with the observed measured readings with respect to the specified values and makes an analysis of extent of deviations from the meaured values ansd give a verdict to the extent the quality is mainatained, gives the decision accpept if well with in spcs and reject if goes out side the limits of tolerances. It is quality control.

Now we can as well have QA where in the inspection engineers involve themselves in the design and manufaturing processes with a clear vision of preventing all the possible modes of failures and arresting them throiugh a system of incorporation of design features or changes. this calls for perfection in the application and domain knowledge.These types of enginerers are seldom sought after for reasons of costs unless it is a premium industry as they are to be involved right from the designs at the table.

the article is illustrative with provisons for both the types of inspectors.or combination of both