It is quite easy to misuse the ISO 2859-1 standard (or its American equivalent, the ANSI/ASQC Z1.4 standard). A common mistake is probably to base the calculation on the number of sets, rather than the number of pieces.

It is quite easy to misuse the ISO 2859-1 standard (or its American equivalent, the ANSI/ASQC Z1.4 standard). A common mistake is probably to base the calculation on the number of sets, rather than the number of pieces.

Why should it be based on the number of pieces? Because that’s the spirit of the statistical rules… Remember, they were developed for the US Army, which was receiving the goods in bulk.

And why do some importers insist on checking production quality based on the number of sets? Because, for them, 1 set = 1 retailing unit. There is usually only 1 barcode for 1 set. There is a logic behind it.

It makes sense for shoes — 1 unit is 1 pair of shoes. But it gets insane when there are too many pieces inside 1 set.

Here is an example to illustrate my point:

- A buyer orders 700 dinner sets.

- Each set contains 94 pcs: 12 plates, 12 saucers, 12 egg holders, 5 bowls, etc.

- He insists to spend only 1 man-day of work, for the QC inspection.

# If we calculate based on the number of pieces:

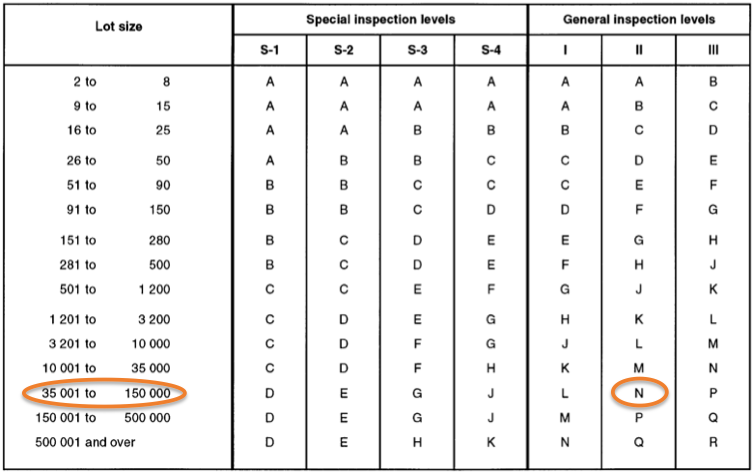

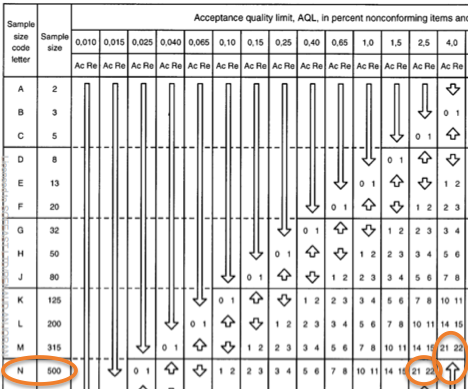

The order quantity is 65,800 pcs. One inspector can check 500 pcs, and that corresponds to level II.

Under this level, 21 major defects and 21 minor defects are tolerated. If the inspector finds 3 major defects in the same set (but on different pieces), he counts 3 major defects. If he finds 3 major defects in the same piece, he counts 1 major defect.

It seems to make sense, doesn’t it?

# If we calculate based on the number of sets:

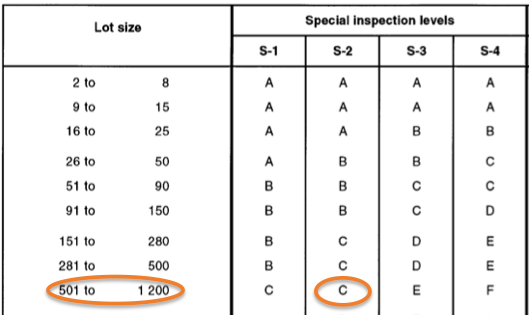

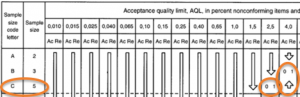

The maximum that can be checked by 1 inspector in 1 day is 5 sets, and that corresponds to special level S-2.

Under this level, no defect is tolerated.

This second example reveals two absurdities:

- The inspector checks 470 pieces (5 sets of 94 pcs), and not a single defect is allowed!

- Inside each set, the inspector can only count 1 defective unit. For example, if he finds 10 major defects and 20 minor defects inside 1 set, he can only count 1 major defect for that set.

Remember, a QC inspection is useful for checking the quality of production… And, in production, 1 piece is 1 piece!

——————

For further reading: Quality Control Basic Concepts

The intention should be to inspect each individual production process i.e. dinner plates probably don’t come off the same line as tea egg holders. Even if they did, it would be a significant change in set up and therefore warrant an individual assessment as to the quality.

So you’d like to do one sampling plan separately for each product? It makes sense, but in this case it is not doable in 1 man-day.

I’m also having trouble understanding the rationale in basing the inspection quantity on a time allocation basis rather than on the tables – how do you justify an S2 level without a satisfactory history ? This doesn’t appear to be any better than randomly selecting a number.

I totally agree with you!

I totally dont understand your way of picking a sample – are you sure about the samplesize ?

Yes. How would you do??

Hello Renaud,

We use just one AQL Level:2,5. We do not add to our table minor defects(AQL:4).

Is it common? Because there are so many parts to measure. And inspector/technician can not know which defects are major or minor. Engineer can know who is expert on product. See our plan at below. AQL 1,5 and control level S-3

It is fine to do your way. Products are either defective or not defective. It works.

Separating defects in several categories and assigning an AQL limit to each category is not THE standard way of doing this. It is just the most common way of doing random QC on consumer goods.