I love to help importers define their product requirements in details. Engineers working on new product developments call it a “product quality manual”. In the quality assurance industry, we call it a “QC inspection checklist”.

I have guided a few importers down this path, and I have identified a clear method to prepare such a document:

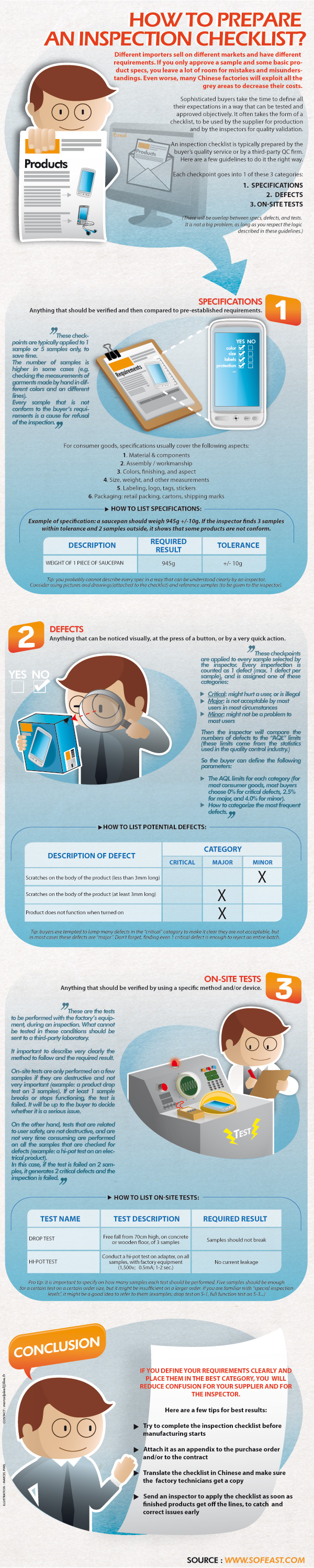

We also prepared it in pdf format: How_to_prepare_an_inspection_checklist.

And you can see this other illustration showing examples of inspection checkpoints.

![How to prepare a QC inspection checklist [infographic]](https://qualityinspection.org/wp-content/uploads/2011/01/shutterstock520432087-1024x535.jpg)

0 Responses

I want to have more of these articles . they are interesting informative and foremost the presentation is interesting.

regards

Anoop Pachauri

Hi Anoop, we’ll work on other similar illustrations, little by little. It takes time to conceive them, and it takes money to have them designed. But they are worth it, I think. Thanks for the nice feedback.

Hi, thanks for the information, I been reading a lot in this site, I am a just gratuated Electronic engineer in Colombia, and many of your recomendations apply to my country.

I am in my first job, and I´m the quality chief on a luminare industry, and I´m plannig to reduce inspection and to start doing checklists, I´ll continue reading any information that will help me to achieve this

Thank You

Juan Jose Correa

Hi Juan,

Thanks for the comment… If you want to reduce inspection, you have to focus on process improvement. And also address the human element (how workers think of their job).

A very interesting and useful artical. Thanks very munch.

Thanks Nancy!

Hello Renaud,

Very useful information!

Please help me with these questions. Let us assume that I have a measure in the specifications point of a product. This size is not a critical measure on the product.

If I have 3 pieces of 5 with a measure out of the tolerance, should I reject the product?

This size is very probably to be erroneous because it’s made by hand and difficult to control. 5 samples are enough to approve or reject the sample?

Should I use AQL for the specifications as well as for the defects ?

Thanks in advance for your reply.

Martin.

Martin,

In that case, you might want to request the inspector to check 5 pcs first. If at least 1 is outside tolerance, he checks 5 more for the measurement point that was out of tolerance. If he finds another one out of tolerance, it is failed.

(Just an example — adapt it to your situation).

I don’t advise to use the AQL for the specifications check.

Hello Renaud,

Thanks for your explanation and advices.

Martin.

Very useful

keep the good work up

really like your article, you reveal the basic principle of inspection, beyonds these rules, I believe a professional and sophisticated inspector have more to do: like reliability testing, safety part, and the consistence. key component, etc

Kiko

Sure, it can get more complex in certain product categories. As you write, these are the basics.

Looking for raw Veneer, that just came off the tree, that is 1/8″ Thick…. comes in sheets ~ wanting it to be cut into smaller pieces.

Thanks

WJaysTEO@Yahoo.com

nice design and awesome explanation..

Thanks!

Hello,

I have tried to download the PDF format but the link is broken.

Could you please send it to me by email.

Sorry about the broken link. Now it is repaired: https://www.qualityinspection.org/wp-content/uploads/2011/01/How_to_prepare_an_inspection_checklist.pdf