This is the third part of the presentation I gave a group of Chinese suppliers, in a Global Sources forum. Links to the previous parts are here: the initial sourcing phase, 6 ways suppliers can cheat buyers.

This is the third part of the presentation I gave a group of Chinese suppliers, in a Global Sources forum. Links to the previous parts are here: the initial sourcing phase, 6 ways suppliers can cheat buyers.

I emphasized the need for suppliers to take quality control more seriously by being more transparent and by thinking long term.

The danger of a short-term perspective

Many factories ship bad quality even when they know it is bad.

Or they play a game, which unfolds as follows. They know a shipment is urgent, but there is a quality problem. They don’t fix the problem, since they know the client will authorize shipment anyway.

This is not a long-term strategy!

Some customers have a very high “lifetime value”. Do not under-estimate it. Losing them means losing a LOT of future profit.

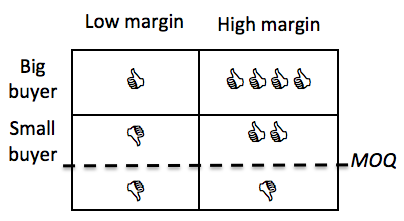

You should probably segment your customers this way, to see which customers you cannot afford to lose.

Extra reading >> If you’d like to learn even more about QC, read our detailed Quality Control basic concepts post here.

Calculation of the value of a good customer

A customer is good if LTV (lifetime value) > CA (cost of acquisition) + CK (cost of keeping the customer).

Calculation of the LTV (lifetime value)

Let’s assume:

- 1 good customer places orders for 3 years;

- Order value is 500,000 USD per year;

- Profit is 25,000 USD per year.

LTV = 75,000 USD per year (average).

Calculation of the CA (cost of acquisition)

Let’s assume:

- You pay 50,000 USD/year in marketing;

- You get 10 good customers a year.

CA = 5,000 USD per good customer (on average).

Calculation of the CK (cost of keeping a customer)

Let’s assume:

- Extra efforts in production (to avoid/fix problems) cost you 5,000 USD per year;

- Little discounts (to compensate for mistakes) cost you 5,000 USD per year.

CK = 10,000 USD per good customer per year (average) = 30,000 USD over 3 years.

Let’s put it together

LTV (75K) – CA (5K) – CK (30K) = 40K in profit over the lifetime of this customer’s relationship!

Let’s change the assumptions a little

If you keep the same customer for 6 years instead of 3 years:

LTV (150K) – CA (5K) – CK (60K) = 90K.

Conclusion

You make a lot more profit per customer if you keep them longer!

Four solutions to keep good customers for longer

1. Have a more professional QC service

It should be independent from the production department. When quality is bad, the QC staff stops the products!

It should produce real inspection reports. A form in Chinese and in English would be best, so that you can share it with your good customers every week.

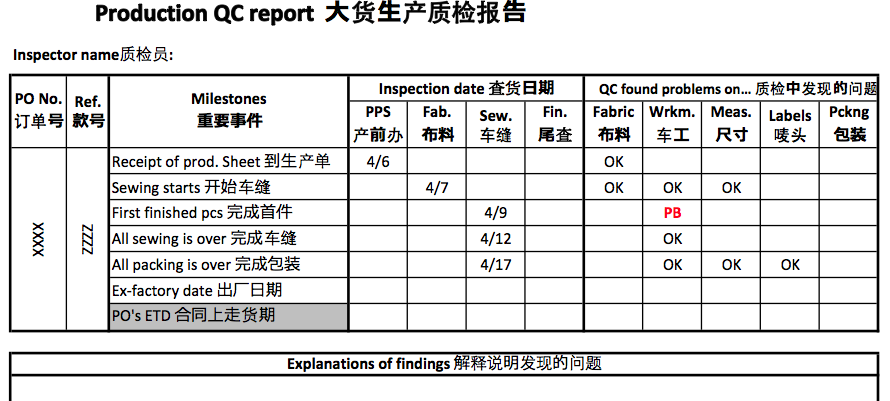

Here are a couple of examples that I shared before in an article about factory inspector training). One can easily see the inspection date, what was checked, and whether there was a problem.

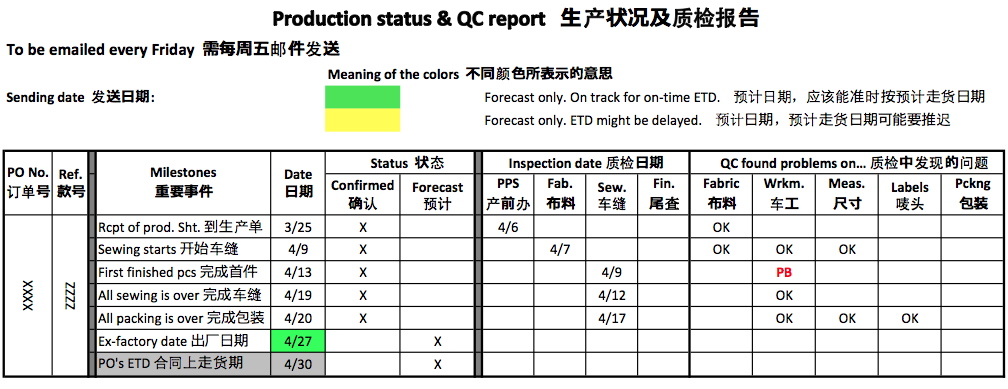

Once a week, copy and paste these data into a more comprehensive form, and emails it to the client:

2. You need to manage orders actively, not “hope for the best”

Just by showing that you manage the order and communicate at regular intervals, you will project a better image than 95% of your competition! I wrote about this before.

For example: send a status update, with revised ETD forecast, every Monday.

Many of you probably work in sales. Try to spend a little time on the factory floor, and understand what is going on. Take the customer’s perspective!

3. Managers need to walk on the shop floor every day, even if it is only for 5 minutes

Observe what happens. Find problems, or ideas for improvement.

If possible, update some simple statistics and show them on a wall: QC pass rate, on-time shipments… This way, you can see the problems immediately and implement corrective actions.

4. Train the workers, if possible on several operations

- Write standard work instructions for each operation;

- Fix the process when mistakes are made. Do not ask who is responsible;

- Make the work itself less repetitive/boring, to reduce staff turnover.

—

What do you think? Any other tips?

Good point, Renaud. I noticed too often that Chinese suppliers’ thinking tend to be nearsighted and bottom line focused. Customer relationship, reputation, and brand equity are lower priorities on their list, and they are giving up the benefit of developing connection and trust with customers and forfeiting the opportunity to command a premium price in the future.

All of the advice you give is right on point, and I would like to add that in order for quality control to be affordable for Chinese manufactures, the control should start happening at the source and manufacturing process instead of after production.

I was talking to the owner of a Chinese furniture manufacturer in Shandong the other day, and they are proud to be manufacturing for brands such as Pottery Barn and Muji. However, the owner is stubbornly performing 100% inspection for the finished products instead of doing a through inspection at the source and identify weakness in the production process any time a defect was sampled in the finished products.

Their control can surely guarantee quality in the short run, however I can sense from the owner’s tone that it is also hurting his bottom line and ability to scale.

Thanks Wayne!

To give you my opinion about 100% final inspection: the very best would be to train each worker to self-check his work (source inspection + containment of errors). But that’s not something a Chinese factory can put together, or even accept, easily.