If you work with Chinese suppliers, you have certainly received a number of messages of this type:

Dear [buyer name]

The price of [main raw material in their product] has increased a lot recently, so we have to increase the price of your product to X.XX USD per piece. We are sorry for the inconvenience caused.

Best regards,

[Supplier name]

How did you react? Did you see it as a lame excuse from the manufacturer, trying to justify an increase of their margin? Sometimes it is true, but not always.

What to do?

First, collect some data. For example, on Steelhome.cn, you can see the prices of copper, aluminum, or nickel:

Second, is it fair to increase the price as suggested by the supplier? If the material price goes up by 20%, should the total product price also go up by 20%?

It depends on the percentage of that material in the final cost in your product.

For a forged metal part, metal consumption is the highest cost contributor, therefore a proportional increase makes sense.

However, I have seen situations where the metal only contributes about 50% of the final product cost, but the supplier requested a proportional increase. That makes no sense.

To deal with such situations, you need to know the raw material contribution on the final cost, from the start. If you don’t have this information, I would suggest to run a quick request for quotation (RFQ) with other suppliers to ensure your supplier is still competitive.

Third, should your product cost always increase?

Chinese suppliers are only requesting a change in price when the raw material price goes up. When the price is decreasing, they forget to mention it.. and, if you request a decrease in cost, you will probably be given excuses — typically, they have old inventory, the price is unchanged, and “honestly, we are are still losing money”.

This is the same as my second point. Get some visibility. Run a quick RFQ and check if your supplier is gouging you.

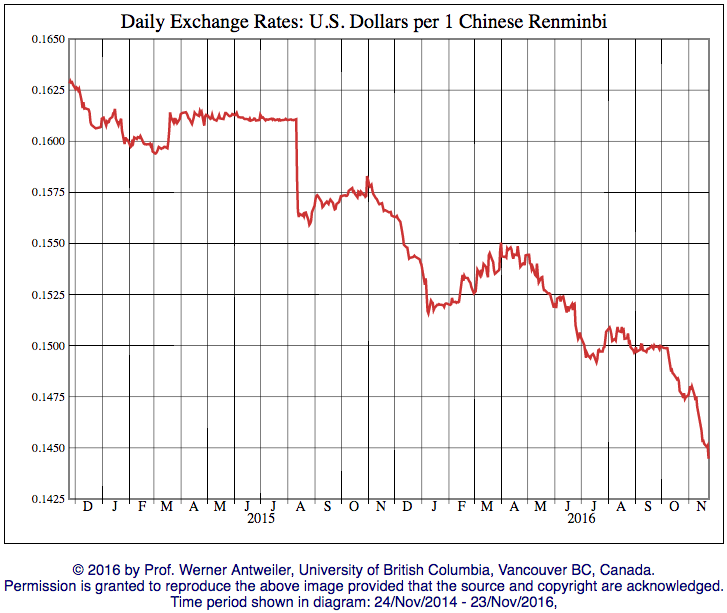

Fourth, what about the RMB (Chinese Yuan) exchange rate with USD?

The same mechanisms are at play here. You will virtually always benefit from indexing your prices on the RMB instead of the USD. RMB payments are more profitable in the long term (especially considering that that China’s currency has been depreciating continuously over the past few years).

As a summary, buying from China necessitates an understanding of the various factors that impact your supply chain. Raw material prices are critical and can have a significant impact on your operational margin. In addition to controlling your suppliers, you can take other measures such as pre-ordering raw materials to anticipate on an increase.

—

Related articles:

Good tips for staying ahead of materials prices to ensure your getting the best price from suppliers in China. In addition to the advice above, I’d add that importers can sometimes review a detailed bill of materials to learn the rough make up of their product. Besides sending an RFQ to other suppliers, this helps some importers determine how material cost increases/decreases should affect the cost of manufacturing.

Yes definitely, that’s what many savvy buyers do, especially when they are specialized in 1 product category.

Good tips considering the current panic over the rising raw material prices over the past few weeks. Are there any suggested web sites to keep an eye on to track the coming increases?

It depends on the type of raw material. You might want to search for “[material name] price” in Google as a starting point.

Here are a few examples of websites where you can get the spot price:

http://www.custeel.com/en/price.jsp

http://newsen.steelhome.cn/

http://copper.ccmn.cn/

Renaud,

Any sources on plastic resin prices and Tin? This would be helpful in educating our customers

when we inevitably have to have the price increase conversation.

Thanks,

Marty Getz

Let them check on alibaba.com!