As part of their quality control plan, importers should decide when final random inspections should take place.

As part of their quality control plan, importers should decide when final random inspections should take place.

As I wrote a while back (see here), each option has drawbacks. An earlier inspection is easier on the factory, and it allows for a faster shipment. BUT the inspector’s conclusions are less reliable and less comprehensive.

My friends at the Quality Wars blog published an article (Performing Final Inspection at less than 100% Packed) that sums up this tradeoff nicely:

The most common time to inspect the goods is when they are 100% completed and packed. This is the safest choice; right for a buyer who has serious concerns about the quality of the goods. Since the goods are 100% packed prior to inspection, the inspection sample will be drawn from the entire lot of goods that is shipping. Therefore, the likely hood that any issues in the shipment, including those related to the packaging, will be identified in the inspection, is very high.

Another common standard, especially for retailers, is that inspections can take place any time after the goods are 80% completed and packed. With this standard the buyer offers a little bit more flexibility to the factory, since production timelines are usually very tight. However, these is always some risk that if the goods are inspected when only 80% is complete, the other 20% that is not complete when the inspection is performed, will contain unidentified quality issues.

The most flexible option would be to allow inspection to take place anytime after 50% of the goods are complete, and not considering how many are packaged. Although this option is extremely flexible, and good for those that are on extremely tight timelines, it opens up a range of issues. The reason for this is if there are quality issues with the packaging or in the part of the shipment that was not included in the inspection, it will not be identified prior to shipment.

I very much agree. An importer of time-sensitive promotional items will often be very flexible, whereas other buyers will require 100% packed — and might ask for inspection abortion when this is not the case.

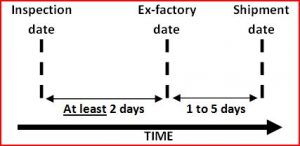

Whatever the acceptable proportion is, there is one thing importers should not negotiate: the time between the inspection date and the ex-factory date. I used to send the below illustration to my clients, to make sure they impose it to their suppliers. I hate working in a rush!