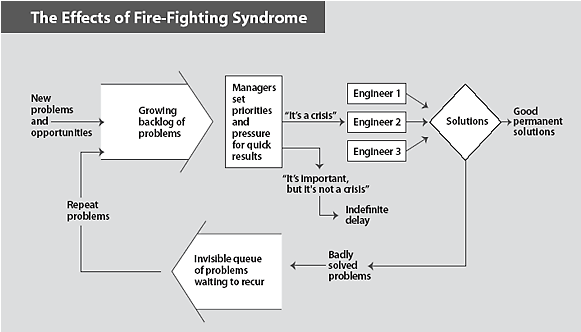

I came up on a really insightful article entitled Stop Fighting Fires. It was published in the Harvard Business Review in 2000 and is still very relevant.

The authors identified the following 6 symptoms that are common to all organizations where fire-fighting takes precedence over continual improvement.

1. There isn’t enough time to solve all the problems. There are more problems than the problem solvers—engineers, managers, or other knowledge workers—can deal with properly.

Here is an example. ‘Two machines are down and hurt production numbers, and customers are screaming for shipment by this weekend. No time to investigate where the big quality issue came from — let’s just put 10 operators on sorting & rework. Oh and let’s try to ship the other quality issues, since those customers don’t inspect quality. And let’s not forget, we need to hire replacements for the 2 technicians who just left.’

That’s what managers think of every day. They react to problems. No need to take initiatives, just see where fires break out and run to the scene.

2. Solutions are incomplete. Many problems are patched, not solved. That is, the superficial effects are dealt with, but the underlying causes are not fixed.

and

3. Problems recur and cascade. Incomplete solutions cause old problems to reemerge or actually create new problems, sometimes elsewhere in the organization.

‘It’s the fifth time the tool breaks on this machine and we are not sure why. Anyway, let’s just order a new tool and pay for express delivery. Let’s hope the new tool is stronger. We are really not lucky — every time it creates hundreds of bad pieces before it fully breaks and the machine stops.’

When will they do a proper root cause analysis and fix the problem permanently? Very seldom.

4. Urgency supersedes importance. Ongoing problem-solving efforts and long-range activities, such as developing new processes, are repeatedly interrupted or deferred because fires must be extinguished.

In the above example, it might be important to take the following steps:

- Hire an engineer or a consulting firm for setting up a preventive maintenance plan

- At the same time, ask the machine manufacturer for their advice

- Training the maintenance technicians to carry it out

- Blocking some time for the maintenance work

- Auditing whether it is done as per expectations

But does it get done? Again, very seldom. It takes time and energy! There are always urgent tasks to take care of first.

5. Many problems become crises. Problems smolder until they flare up, often just before a deadline. Then they require heroic efforts to solve.

‘Oh the sales person collected some information and says we are late on 5 POs. The customer says we have to ship 50% of the quantity by air if we are more than 10 days late, and it seems we’ll be 15-20 days late. Let’s all push very hard to get those productions out the door in time. All other orders have to wait for now. The workers will have to pull out a couple of all-nighters if needed, and let’s hire 10 temps.’

And then what does the owner (who observes all this from a distance) think of his production manager, if the goods are shipped on time? He’s a hero!

In a better run organization, some people would be asking why the production planning system didn’t detect this risk earlier, why many orders were taken and the capacity couldn’t accomodate them, and so on.

6. Performance drops. So many problems are solved inadequately and so many opportunities forgone that overall performance plummets.

In the long run, this type of organization ends up suffering very, very much. They will get new customers and lose them after a while. Key engineers and managers get tired and leave. The boss complains how hard it is to “get to the next level”.

So the question is, what can a factory do to get out of this situation?

It is not easy but one could say the solution is rather simple. As the authors suggest, it is important to follow a good approach to problem solving. Problems get root-caused and permanently fixed one after the other. It looks a bit messy for a while, but then there are fewer and fewer problems and the overall performance improves.

What does such a problem solving approach look like? I shot a video that explains our improvement framework. That’s a good place to start. I hope it is useful.

good to review and will see how much I can do