Last week, on Linkedin, I ranted about the many (not all) Chinese manufacturers that “fail to plan appropriately, are over-optimistic, and disappoint their customers with last-minute shipment delays”.

Someone commented that I should offer “good advice” to these suppliers instead of complaining. And that’s right, so here goes…

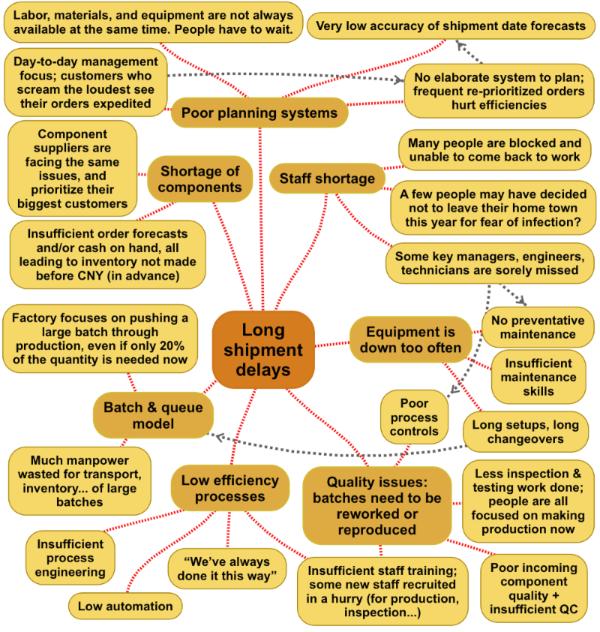

Analyzing what causes shipment delays at the level of each factory

The first step is to analyze the problems at the level of each factory. There are usually many factors contributing to repeated shipment delays, so identify the major factors. After that, working on those factors is sometimes very straightforward and sometimes a long and hard process.

Based on my experiences with Chinese factories, here are the usual underlying issues.

(There’s a lot of information to take in, so I drew a mind map to make it a bit more visual.)

Note that I only listed the ‘hard’ factors. One could also add ‘soft’ factors such as:

- A salesperson’s eagerness to please customers with good news, even if bad news will have to be announced a little later;

- A manager’s strategy to announce delays a few days at a time, rather than saying the truth (“3 weeks late”) up front, as the latter approach often trigger a strong pushback from customers.

‘Hard’ factors that reoccur and cause delays

Here is the list of ‘hard’ factors I have seen at play in many situations. If you are aware of them, you can plan to avoid or improve them with your supplier:

#1. Poor planning systems

- Day-to-day management focus; customers who scream the loudest see their orders expedited

- Labor, materials, and equipment are not always available at the same time (when needed). People have to wait.

- No elaborate system to plan; frequent re-prioritized order hurt efficiencies

- Very low accuracy of shipment date forecasts

#2. Staff shortage

- Many people are still blocked and unable to come back to work (due to the current COVID-19 restrictions)

- A few people may have decided not to leave their home town this year for fear of infection (this one is speculative… I am not sure it is a big factor)

- Some key managers, engineers, technicians are sorely missed

#3. Equipment is down too often

- No preventive maintenance

- Insufficient maintenance skills (especially when key technical staff is missing)

- Long setups, long changeovers

#4. Quality issues: some batches need to be reworked or reproduced

- Less inspection & testing work done; people are all focused on making production now

- Poor incoming components quality + insufficient QC

- Insufficient staff training; some new staff recruited in a hurry (for production, for inspections…)

#5. Low efficiency processes

- Insufficient process engineering

- Low automation

- “We’ve always done it this way” mindset

#6. Batch & queue model

- Much manpower wasted for transport, inventory… or large batches

- Factory focuses on pushing a large batch through production, even if only 20% of the order quantity is needed now

#7. Shortage of components

- Component suppliers are facing the same issues and might prioritize their main customer(s)

- Insufficient order forecast and/or cash on hand, all leading to inventory not made before CNY (in advance)

Now, what about your factory, or your supplier’s factory? How many of these issues do they display in their operations & systems? Let me know by leaving a comment.

Related reading: the team at China Manufacturing Consultants wrote COVID-19: Recover China manufacturing with our Production Expediting Service on this topic, too.