China is fighting tooth and nail to contain the current wave of covid infections. And this is going to be a long and painful battle.

Most people I talked to do not believe Beijing will change its “covid zero” objective anytime soon. They recently adapted it a bit to “dynamic zero“, but the objective remains zero.

In short, there are outbreaks all along the East coast, and hyper-connected megacities like Changchun (in the Northeast, home to very large VW production facilities) and Shanghai (no need to explain how large and important that city is?) have been placed into full lockdown.

In South China, there seems to be a clear pattern that makes it worse. One city sees an outbreak, and it contaminates its neighbors, and the dominos start to fall one after the other.

1. Hong Kong: high infection rate, no lockdown

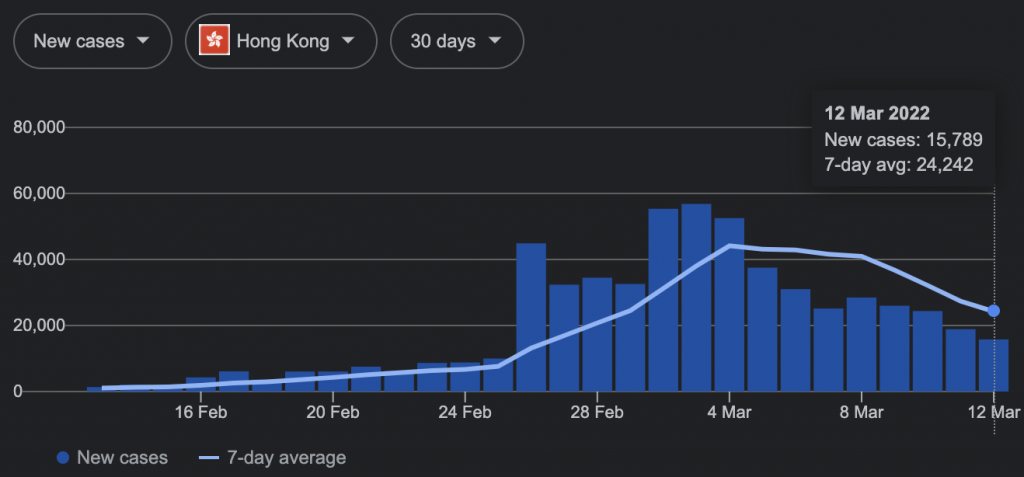

The territory is going through a pretty serious wave. The numbers are relatively high for a total population of about 7 million. And the numbers are deceptively low — many people stay home and don’t self-declare to the authorities, for fear of being sent forcefully to an unappealing isolation facility.

(Source: Google)

2. Shenzhen: situation getting out of control, strict lockdown

What city stretches all along the land border of Hong Kong? Shenzhen. And the border points are not completely shut. Not surprisingly, outbreaks appeared.

There has now been strong pressure to contain those outbreaks for several weeks. Certain small districts and apartment blocks have effectively been locked down. The manufacturing areas, more to the North of the city, were generally not affected. Until now.

Shenzhen is an enormous city of 17 million. It is dense. The different districts are very well connected by metro, buses, and motorways. Not easy to contain a very infectious disease…

The local government announced a 1-week strict lockdown yesterday night (Sunday, March 13).

Yes, even the gigantic Foxconn manufacturing facility is now stopped. This will have an impact on a lot of supply chains…

Here is a summary of the measures:

- The whole population will have to be tested (nucleic acid method). People absolutely have to go to a testing center on the prescribed days & times.

- Except for staff working on epidemic prevention tasks, all government staff have to work from home.

- All non-essential activities (i.e. all those except for utilities, supermarkets, telecommunications, pharmacies and clinics…) must cease and the staff has to work from home.

- No public transportation. Buses and metro are suspended.

- People have to stay in Shenzhen, except for special cases.

What impact for importers? Well, Shenzhen is a massive industrial base for consumer goods, especially when it comes to electronics. This means no production this week. And who knows how long the lockdown will be enforced.

Oh, and if your manufacturers are in Dongguan, Huizhou, Zhongshan, or other cities in the general area, they might be buying a few specialty components from Shenzhen. That’s not unusual at all. When one component is missing, can your production be running?

3. Neighboring cities (Dongguan, Zhongshan…): some districts locked down, full cities in lockdown soon?

After Shenzhen, it will be its neighbors’ turn!

There are already partial lockdowns in Dongguan and in Zhongshan. There is a relatively high chance a full city lockdown will be announced in the coming days.

And after them? We shall see…

The impact on manufacturers

If a factory producing non-essential goods is located in an area that gets locked down, one can expect they have to stop production. Implementation differs from one city to another, but that’s the general rule.

If at least 1 employee has been in contact or close contact with an infected case (for example, an auditor went to visit a supplier’s factory), and that 1 employee has come back to their employer’s factory, that factory has to be locked down. But it is rather special… in Dongguan, for example, all the staff may have to remain within their factory for 14 days. Or they might be moved to an isolation facility.

Does that mean production can keep going? Maybe it will be allowed, maybe not. And maybe some components are missing (and, of course, the factory cannot receive any deliveries during that period.)

If I sum it up in two words, this is highly unpredictable. And we are not optimistic.

In a way, we knew this was coming. A Dan Harris wrote on 31 Dec. 2021: “Omicron will likely lead to shutdowns of China’s factories”.

Conclusion

All this will also lead to lower air cargo capacity, which adds up to the effect of Russian sanctions (see my article of Saturday on this topic here) and will probably keep pushing the price of logistics even higher.

2022 is not going to be fun for companies manufacturing in China.