A client asked me an interesting question:

A client asked me an interesting question:

If we base on AQL, how many pcs with defects will still be in bulk when shipping ?

In other words, the inspectors find some defects during a random inspection, and these defects are supposed to be removed and/or corrected… but does it make a difference in the end?

Does it reduce the total number of defects significantly? Or are random inspections only useful in getting an estimate about a production batch’s average quality?

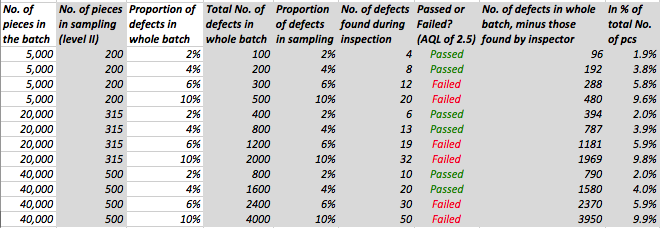

I simulated several situations, based on a few hypotheses:

- We only consider major defects (to simplify this exercise);

- Inspections are under level II, with an AQL limit of 2.5 for major defects;

- Proportion of defects is exactly the same in the whole batch AND in the sample drawn randomly for inspection (it is not exactly true, but usually these proportions are not VERY different).

- Factory re-works or replaces the defects found during inspection (not always the case because the inspector cannot stay overnight and watch this).

The results are clear: the defects found by the inspector, even if they are re-worked / replaced by the factory, don’t reduce the proportion of defects in a significant way.

The value of random inspections based on AQL is to detect if there are problems, in a cost-effective way.

If you also want to sort defects out, it becomes much more labor-intensive (and expensive).

There are intermediary solutions, based on a dynamic sampling plan: if the batch looks fine, it’s passed; if it’s above a certain limit, we go more in depth; and so on. You can read about such an example here.

Does it make sense?

Hi Renaud,

I agree completely, Inspections are about information, not action. Then you must use this information to take the best action. Here’s what Hornet Group normally do:

1. If the inspection shows no quality problem, we ship the goods for our client as per original schedule.

2. If the inspection shows a quality problem, we discuss with our client and choose:

a. negotiate a reduced price because the quality is not up to standard. We only pay a deposit upfront so we have a strong negotiating position.

b. require rework of the entire order

c. both the above

What is best depends on client needs and level of quality problem. If clients need the product urgently, sometimes the only option is to negotiate price down.

Fortunately we vet factories carefully so we don’t often have quality problems!

Hi Bridget,

Thanks for sharing the way you work. I guess most buyers do this way, too.

You are right, the key is to work with good manufacturers.