Two weeks ago I attended the always interesting Made In Asia conference. Two speakers touched on the upcoming changes due to the TPP and the AGOA trade agreements.

Two weeks ago I attended the always interesting Made In Asia conference. Two speakers touched on the upcoming changes due to the TPP and the AGOA trade agreements.

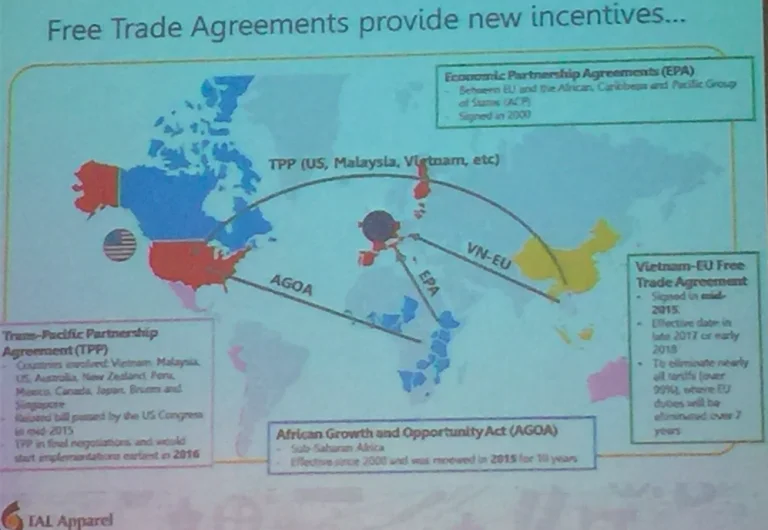

A representative of TAL Apparel shared this slide with us and I thought it was interesting (click the image below to enlarge).

Like many companies, they studied free trade agreements. Since they sell mostly to American companies, East Africa is becoming quite interesting.

(Note: West Africa is geographically closer to their market, but it tends to be more dangerous and more focused on extracting natural resources than using their people’s labor.)

They considered a few important numbers when reorienting their sourcing strategy:

- 700-900 USD per worker per month in China, versus 250 USD in Vietnam and 60 USD in Ethiopia

- About 10% of the full garment cost to be paid in import duties if the goods come from certain countries, versus 0% in other countries.

I don’t know the number for TAL Apparel, but let’s pretend labor cost is 25% of the full landed cost of a shirt. Moving from China to Ethiopia will get that number down to 2% (provided productivity is equal)!

The gap in wages brings in much higher savings than the avoidance of import duties. But I bet a shorter supply chain, resulting is more accurate forecasts (more pieces to sell when the style is hot, and less overstock to dispose of), can yield even higher benefits.

Tal Apparel zoomed in on four countries and studied them carefully:

- Tanzania (stable, low inflation, a bit of political uncertainty, scarce talents, has ports)

- Ethiopia (good government, business friendly environment, has ports)

- Kenya (good government, low inflation, labor a bit more expensive)

- Uganda (less developed than Kenya)

In the end they chose to establish a production facility in Ethiopia.

I noted some of the downsides they listed regarding production in Ethiopia:

- Buying most materials from Asia (longer supply chain, more time consuming)

- The need to teach workers why they need to arrive at work in time etc.

- Low productivity, at least at the start of operations

- Scarce managerial talent

- Frequent power shortages

To answer your question – yes, they are useful and China has entered in many FTA. They can and do change the shape of supply chains. See my China FTA article here: http://www.china-briefing.com/news/2014/02/10/understanding-chinas-free-trade-agreements.html however bear in mind that attention needs to be paid to detail – issues such as rules of origin kick in, and even within the China-ASEAN FTA you mention, not all ASEAN member countries are in full compliance – Cambodia, Laos and Myanmar still have a way to go. Plus other factors such as productivity also come into the mix. Generally speaking, FTA with a country or bloc that contains relatively well establishing manufacturing plants are worth looking into. Productivity however remains the key economic determinant. – Chris

They do change the shape of supply chains — true. For example most garment production in Vietnam seems to be shipped to the US, while in Myanmar it is for Europe.

I fully agree that productivity is the key determinant. More attention should be paid to it — not just measuring it, but improving it.

The complexity of the supply chain is also an issue (buying fabrics in China, shipping them to Ethiopia, then shipping the whole garment to the US: it means many little things can go wrong and create delays.)