Inexperienced importers usually ask the same questions, one of which is: when should we inspect the quality of our products?

Inexperienced importers usually ask the same questions, one of which is: when should we inspect the quality of our products?

There are mainly two types of inspections:

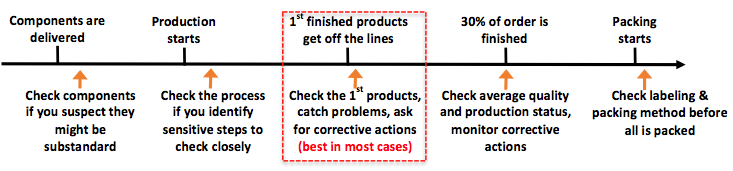

Inspection during production: very useful to catch problems early, when corrective actions can still be implemented and schedules can be updated. It should target the main risks identified by the buyer:

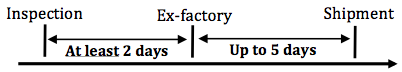

Final inspection (after packing): the bare minimum for most productions. The only time an inspector can pick up samples totally at random. The timing is virtually always the same:

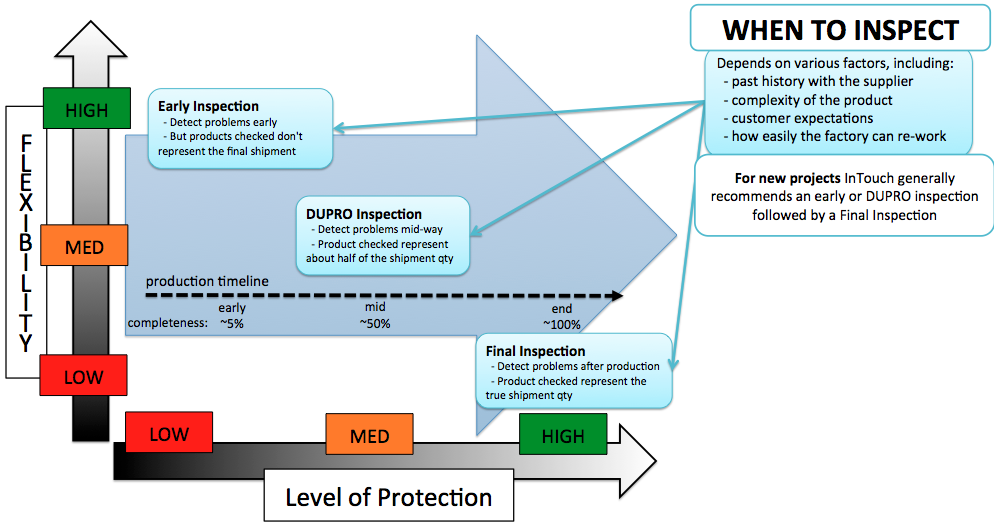

My friend Andrew Reich from InTouch just published a useful infographic that captures all these nuances (click on the image to enlarge it):

Is something missing? What do you think?

The simple rule, we apply for the member of http://www.eyo-alliance.com

– You can not accept any delay on delivery: inspection one week before the delivery

– It’s the first production with this company: inspection in the middle of the factory

– Modification of a prhttp://www.qualityinspection.org/inspect-during-after-production-china/#oduct already product: inspection of the first finish pieces.

This allow 80% of the time, to correct mistake, misunderstanding, error ….

The early resolution of trouble have a very great and beneficial impact on your delivery time of correct product.

That sounds like good rules. Thanks for sharing them with us, Gaetan.

One step we like to add is a quality plan clarification meeting. This is not an inspection but more a meeting and focus audit of the QC measures taken routinely by the supplier, an review of what we or our client want to be monitored, a discussion on possible special QC measures for this order and most importantly, a final check to confirm that the supplier fully understand all requirements.

At the end of the day, we are all better off if the supplier gets it at the outset.

That’s a HUGE plus, I totally agree.

I call it an explanation of the checklist to the manufacturer, and collection of their feedback, before production starts.