As the US-China trade war intensifies, many American importers are looking for alternatives. They often look at Vietnam, Thailand, Indonesia, India, Mexico, etc.

But what about Taiwan? There is sometimes an opportunity to start sourcing products from there, especially in electronics.

Some great points about Taiwan as an alternative manufacturing location to Mainland China

I had the opportunity to ask questions to Case Engelen, the CEO of Titoma – Design For China Manufacturing, who has been working in electronic product development & manufacturing in Taiwan and China for 25 years. He made some great points about manufacturing electronics in Taiwan. Here are the Q&A’s:

Q: What are the main types of products Taiwan factories export, particularly in the electronics industry?

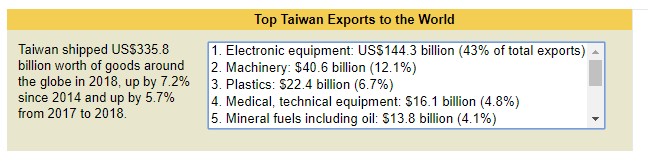

Taiwan is mostly known for exporting all sorts of electronics. It includes final products such as notebooks, but also countless component types such as power supplies, modules, camera lenses.

TSMC is the world’s largest contract IC maker. They also have fabs in China, but they keep their latest technology in Taiwan.

Q: What are some types of products that can be made with a proportion of Taiwan-made components & materials sufficient to avoid US tariffs?

I am not sure about the exact % needed, we need to ask Dan Harris, but if PCBA and final assembly are done in Taiwan I would think that there is enough value added in Taiwan to call it MIT: Made In Taiwan.

Five out ot the 10 top EMS’s are Taiwanese, which is quite impressive for a country with only 24 million people.

(Note: if you click on the link above, you will count 4 are based in Taiwan and in addition Universal Scientific Industrial, part of the ASE group, recently got on the Shanghai stock market but is still very much Taiwanese managed.)

If you look at the world’s top 10 ODM’s (companies which design AND manufacture on behalf of their clients) you’ll find ONLY Taiwanese companies.

By the way, for some practical tips from Case on how to avoid the pitfalls in working with ODM’s, please see https://titoma.com/blog/china-odm-factory-designs-7-pitfalls-to-avoid.

Q: But the vast majority of the assembly done by those ODM’s and EMS’s is outside of Taiwan, right?

It’s important to remark that the top 10 EMS’s all have most of their factories in China, but as for ownership, none are Chinese!

Apparently, the big Western and Japanese electronics brands do not trust Chinese management enough to “go China direct”.

Q: Why are Taiwanese companies so good at doing all the design-development-manufacturing?

Taiwanese companies are known for good quality, reliable production lead-times, fair prices, and good business practices.

A lot of trust is required to ask another company to do both design and manufacturing. Developing a new product often takes more than a year of effort and a high budget.

As a customer, you invest an awful lot in the relationship: time, fees, and IP. Having invested that much in a venture, a customer becomes vulnerable to extortion, because moving a complex product to a different partner will take again a lot of time and money, while the market window for the product is shrinking.

A good partner does not abuse the trust placed in him. Ten out of the top ten ODMs being Taiwanese makes for a pretty strong vote of confidence for Taiwan. There simply is no better place in the world to have your electronics designed, and your manufacturing managed.

Your say…

Lithium-Ion Battery Safety Guidelines For US Imports

Sofeast’s Lithium ion battery safety guidelines for US imports whitepaper is aimed at manufacturers who are producing goods requiring these batteries in China and Asia and seeking to ship them to the USA for sale. In it, we cover everything you need to know about shipping these batteries to the USA, including recalls, product & transport safety, compliance recommendations, and more.

Get your free copy by hitting the link or button below: