The nature of products exported out of China is changing. This is an important trend, and all importers should be aware of its implications. China’s manufacturing sector is “moving up the value chain”, and it follows the same pattern as South Korea or Taiwan in the 1970s and 1980s.

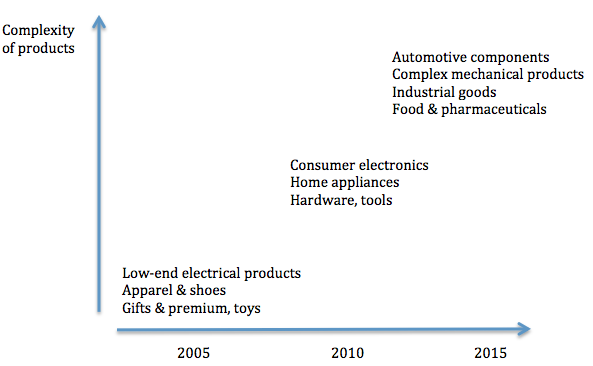

Basically, the mix of exports is changing, from simple products (apparel, shoes, toys) to more technologically advanced and higher-margin goods:

Does it mean that quality is going up?

In a given industry, quality is not necessarily improving.

For example, let’s say you purchase garments in China. You are probably under pricing pressure, and it pushes you in the arms of lower-grade factories that were opened recently… In places along the coast like Shantou or Quanzhou. Or more to the inside, like in Nanchang city (Jiangxi province).

New factories are usually less experienced and tend to produce lower-quality products. Yet they are slowly replacing the older factories based around Dongguan. It keep the average quality down.

On the other hand, for high-complexity products, quality has definitely been going up. The reason is, importers cannot afford to receive a substandard shipment, and everybody in the supply chain has understood it.

What forces are behind this trend?

First, China is less and less cost-competitive, when compared to other emerging Asian countries. The industries that depend less on the cost of labor and more on technological know-how will make up more and more of China’s manufacturing sector.

Second, the central government has understood this trend, and it will not slow it down. Steve Dickinson wrote a very clear article (Factory Closings In South China. All Part Of The Plan) about Beijing’s position:

The 12th Five Year plan clearly states that a primary goal is to eliminate low value added/high labor content export manufacturing from the entire coast. The intent is to shift to high value added, technologically advanced manufacturing and modern services in this region.

It is important to understand that the vast majority of these export based manufacturers are not economically viable. They exist because of VAT rebates, open violation of the Chinese wage and labor laws and subsidized energy and raw material prices. They have been tolerated in the past solely because they provide jobs.

What do you think?