In a previous post, I explained how to reduce product safety risks by doing a risk assessment based on ISO 10377. It is the preventive approach to avoid distributing an unsafe product (for general consumer goods, anyway). It goes hand in hand with another standard, ISO 10393, which provides guidelines for what to do, including a product recall program, when a consumer product is found to be unsafe and/or non-compliant once it is on the market (in a reactive manner):

ISO 10393:2013 provides practical guidance to suppliers on consumer product recalls and other corrective actions after the product has left the manufacturing facility. Other corrective actions include, but are not limited to, refunds, retrofit, repair, replacement, disposal and public notification.

Now, should you want until you have to recall products from the marketplace?

That’s not advised. This standard actually helps you get prepared so you make good decisions and execute them well.

To simplify, here is what you need to prepare:

- Have guidelines to help you make the right decision and notify the right people/agencies quickly (fast reaction);

- Have a procedure for how to initiate and manage a recall of products currently distributed through the supply chain (warehouses, stores, in transit, consumers/users’ hands…);

- Set up a recall management team in advance, so the roles & responsibilities are clear;

- Collect the right information in advance so the recall only concerns a portion of the products.

Is there a method for putting a product recall program in place?

As part of its guidelines, the ISO 10393 standard helps set a whole program that ensures the company is ready.

A good part of the standard deals with the way to collect information and make the right decision. No company takes a product recall lightly. It can be very costly and undermine customers’ confidence for years to come. And it may tip off some regulators about compliance issues they might not have noticed, hence a hand-wringing dilemma in certain cases.

You may want to have a few product recall program guidelines written in advance, and the phone numbers of a good lawyer and compliance consultant. For example, at the time of the huge VW fraud regarding air emissions, the executives in HQ should have been briefed very clearly that early cooperation with American regulators is expected in order to avoid gigantic penalties… They played the wrong game, and as a consequence, they had to refit 11 million vehicles (and offer to buy back 400,000+ cars in the USA).

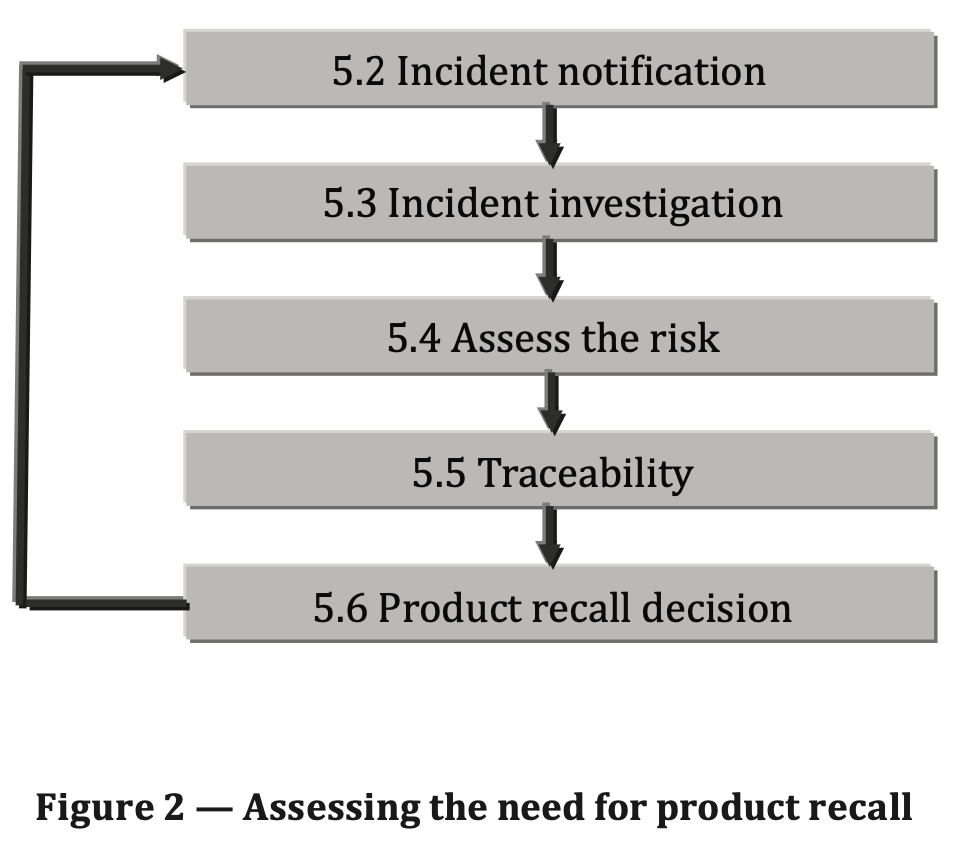

The clauses that deal with these steps are listed below:

(Note: even for consumer goods, specific compliance requirements may apply, especially for toys, electrical products, and so on, depending on the markets of sale. Those requirements must be taken into account.)

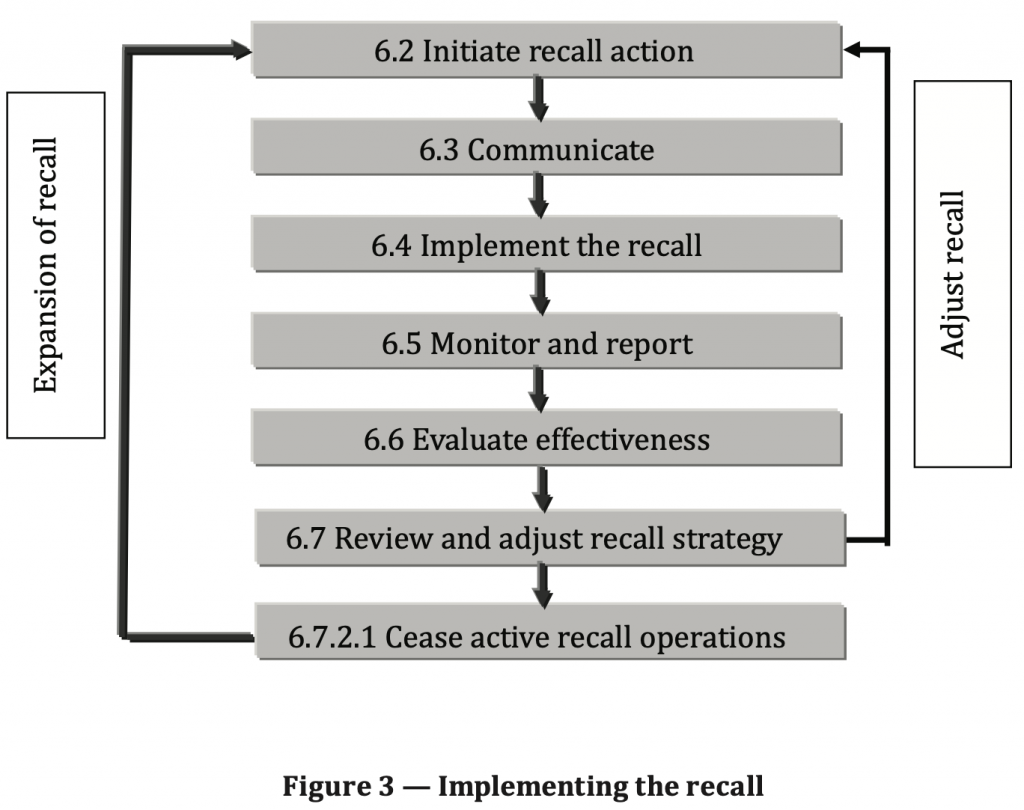

And then, if the decision is “yes, we have to do it”, the logical process is outlined below:

There are a lot of important questions to answer:

- We recall some products, but which ones? How can people know what is recalled? (e.g. Batch number and item number, etc.)

- The items must be sent to where? A repair facility? A warehouse? Will your local service technicians come and pick them up?

- What will your company do with those items?

- What are good practices for managing the recall and communicating about it?

- How to tell the finance department and the investors what the financial implications will be?

- How to work with key distributors and suppliers on this project?

What about more highly regulated products?

In many cases, either regulatory bodies or big customers’ contracts mandate a very specific approach.

For example, the US FDA has requirements about what they call Recalls, Corrections and Removals (for Medical Devices). There are basically two categories:

- Voluntary recalls: what approach to follow, and guidelines about the recall letter

- Mandatory recalls: the FDA is much more prescriptive about what exactly to report, how to report it, and to whom, etc.

Do you just do the product recall, fix the products, and move on?

If you don’t want this painful, costly, and embarrassing incident to come back in a few months/years, you need to follow a proper corrective action plan:

- Identification and early analysis (done before the recall)

- Containment of bad products (that’s the recall)

- Correction (that’s fixing some/all the products)

- Root cause analysis

- Implement countermeasures

- Confirm the effectiveness of those countermeasures, and circle back if needed

- Learn from this and apply that learning broadly in the company

In conclusion…

Unfortunately, most companies do steps 1, 2, and 3 from above and never change their old habits (or their key suppliers’ habits)… and they remain exposed to recalls.

In some cases, the root cause is a toxic corporate culture. To refer back to the VW scandal, the company seemed to learn nothing from the Lopez corporate espionage affair or the prostitution scandal. They did not strengthen their internal controls, they kept their authoritarian, top-down management style, and the CEO kept telling engineers that “nothing is impossible”… And all that led to a massive fraud that had profound consequences — including the rush of many governments to accelerate the switch to electric vehicles. Hopefully, the VW group has learned something from that scandal.