Putting the design of a new product idea that is going to be manufactured on paper (sketches) and in 3D drawings (computer-aided design) is usually not sufficient to confirm all aspects of the design. Before proceeding to tooling fabrication, certifications, component purchasing, and manufacturing, you will certainly need to make physical renderings by doing prototyping in China.

Table Of Contents

Keep reading, or hit the following links to skip to the section you’re most interested in:

- Getting started with prototyping

- Which type of prototyping company is better for my needs?

- Prototyping companies in China who offer design support for end-to-end product development (proof of concept to prototype)

- Prototyping companies in China who create PCBAs & software for electronics

- Traditional prototyping companies in China who focus on rapid prototyping using the designs they’re provided with

- How to get a high response rate when asking for help to get a prototype made?

- Conclusion

Getting started with prototyping

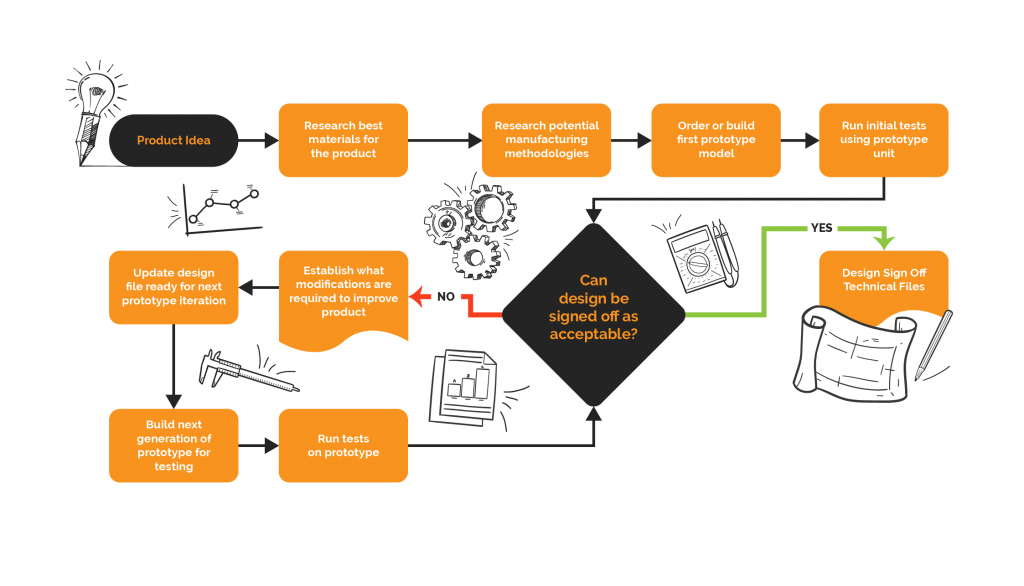

You might start with a 3D printed rendering (to confirm the overall aspect and size) and/or with a rough ‘proof of concept’ to confirm a key functionality. Then, you will probably need to make look-alike and work-alike prototype.

Here is a simplified view of that process:

Which type of prototyping company is better for my needs?

You need to understand what type of value you need your prototyping supplier to provide. Let’s assume you already have the drawings, schematics, etc. What is your need?

- ‘Just do it’ — most prototyping companies receive CAD drawings and a material spec, and produce some parts, without critical thinking. That’s what you can expect of most “rapid prototyping” companies because it goes straight from input into output. This is great if all you need is 1 or 2 components to play with, for a proof-of-concept.

- ‘Review, provide suggestions, and then do’ — all designs, even if they were prepared by an experienced person, need to be reviewed and challenged (it is a ‘Design for Manufacturing” review). The prototyping process is actually part of the validation of the product design. If you expect this type of assistance, you need to assess the prototyping service provider’s engineering capability. This is important for the final prototype, especially for a full product that includes many parts.

- ‘Review, suggest, do, but also check and test’ — In addition to the above, they translate your requirements into specifications and test plans, they organize those tests on the full product, and they provide their suggestions on how to get better performance/reliability. This is what you can expect from a full-blown R&D center.

In addition, you may want to know what processes they have in-house. It is very common for prototyping companies to rely on a network of subcontractors, and this may create intellectual property (IP) control issues.

You will also see that many companies do prototyping but also manufacturing. If they are upfront about their business model, and if you sign a clear agreement that indicates you will own all the IP, that’s fine. Otherwise, make sure you don’t end up working with an OEM or ODM that doesn’t want to send you the latest versions of the drawings and schematics, doesn’t want to tell you where they sourced the parts…

Here is our list of companies that provide prototyping in China. They mainly provide similar services, for example, ‘CNC machining’ and ‘plastic injection molding’ are pretty universal amongst them, however, some provide design support on the R&D side and some also provide PCBA services for electronics manufacturers looking for a more turnkey approach, so they will be categorised accordingly:

Prototyping companies in China that offer design support for mechanical parts

1. Vowin – Shenzhen

Founded in 2008, Vowin holds ISO 9001:2015, and 14001:2015 certifications and not only provides rapid prototyping for all kinds of materials and products but also has in-house industrial design capabilities, too. They have produced parts for most industries, notably automotive, consumer electronics, and industrial parts.

- Key services provided:

- Rapid Precision Machining

- High-volume Machining

- Plastic Injection Molding

- Silicone Vacuum Moulding

- Instant Pressure Die Casting

- Die Casting/Stamping

- Fast Sheet Metal Fabrication

- Design support services? Yes, CAD Design, 3D Scanning, Engineering Review

2. Soma Prototype – Shenzhen

Shenzhen’s Soma is a prototyping specialist who has experience creating prototypes for clients in digital communications, automobile, household appliances, medical devices, and more. They are focused on rapid prototyping and low volume manufacturing.

- Key services provided:

- CNC Machining

- Sheet Metal Production

- Rapid Injection Molding

- Surface Finishing

- Aluminum Extrusion

- Design support services? Yes, they can provide some product development advice.

3. RebondTech – Hong Kong/Dongguan

Rebond is a diversified industrial manufacturer of high-quality customized metal and plastic parts since 2005. They serve a wide range of industries, ranging from machinery, automotive, electronics to consumer goods, transportation, medical, telecommunication and more.

- Key services provided:

- Rapid Prototyping

- 3D Printing

- CNC Prototyping (Turning &Milling)

- Vacuum Casting

- Injection Molding

- Metal Stamping

- Finishing

- Design support services? Yes, they provide part design in-house upon request.

4. Able Industrial Design & Technology – Hong Kong/Dongguan

Founded in 1990, Able provides product development, rapid prototyping, and rapid tooling. They have created prototypes for clients in the rail, medical, solar, toys, automotive, and electronics industries, to name but a few.

- Key services provided:

- CNC Machining

- 3D Printing

- PU Casting

- Reaction Injection Molding

- Sheet Metal Prototyping

- Rapid/Production Tooling

- Small Batch Production

- Design support services? Yes, they provide 2D to 3D CAD translation, development of an initial idea to a full CAD model capable of producing a rapid prototype component, and project management of the whole process, from concept to production.

5. RapidDone – Shenzhen

RapidDone started out creating parts and products in 2008. They have delivered over 2000 projects among several industries like Automotive, Medical Devices, and Consumer products, and have a particular specialism in high precision CNC machining.

- Key services provided:

- CNC Machining

- Plastic Prototype

- Metal Fabrication

- Injection Molding

- Custom Machined Parts

- Design support services? Yes, provides assistance with material selection, final feature design tips, and cost-saving.

6. Apt Mold – Zhongshan

APT Mold Manufacturing Co. Ltd. specializes in rapid prototyping, rapid tooling, and low-volume manufacturing as well as mass production. Unlike some prototyping companies, they also provide suggestions for DFM (Design For Manufacturability) as standard in order to optimize designs and reduce manufacturing costs.

- Key services provided:

- Plastic Injection Molding

- Rapid Prototyping

- 3D Printing

- Precision CNC Machining

- Low Volume Manufacturing

- Custom Metal Stamping

- Finishing

- Design support services? Yes, DFM in-house and product design via a USA-based partner.

7. LK-Mould – Dongguan

LK-Mould has been operating for more than 2 decades since 1998 and specializes in steel and aluminum tooling for plastic injection molded parts and products making over 500 sets of tooling each year for companies in Automotive, medical industry, electrical engineering, sensor technology, engines, and more. In addition, they hold ISO 9001:2015 and IATF 16949:2016 accreditation.

- Key services provided:

- Injection Moulding

- Rapid Prototyping

- Plastic Molding

- 3D-Printing

- CNC-Prototyping

- Design support services? Yes, they provide in-house mold and part design and development.

8. WayKen – Hong Kong/Shenzhen

WayKen is one of Guangdong’s more established prototyping providers with a 20+ year history. ISO 9001 certified, they specialize in prototype machining and low-volume production for custom parts, providing one-stop services from prototype to production including providing design support at the product concept stage.

- Key services provided:

- Industrial Design Prototyping

- Design support services? Yes, they provide prototype concept design and ID prototyping in-house.

Prototyping companies in China who create PCBAs & software for electronics, too

9. Agilian Technology – Dongguan

A specialist in electrical and mechanical product development, prototyping, and assembly, Agilian was founded in 2018 and is located very near to Shenzhen airport and Hong Kong’s border. As well as on-site industrial design support, Agilian provides not only rapid prototyping, tooling development, but also comprehensive software, PCB development, and PCBA production capabilities for clients developing electronic products. They have been involved in the prototyping and production of numerous consumer electronics and products such as vapes, IoT wearables, silicone molded products, jewellery, and more.

- Key services provided:

- PCB Design & Prototyping

- PCBA Development and Assembly

- Firmware Development

- CNC Milling/Turning

- 3D Printing

- 3D Scanning (0.005mm precision)

- Plastic Injection Molding

- Thermoforming

- Laser Engraving & Cutting

- Silicon Compression

- Plastic & Aluminum Extrusion

- Zinc & Aluminum Die Casting

- Design support: Yes, in-house DFM support & review, structural and mechanical design, electronic design, CAD drawing, mold design

Fair disclosure – I’m executive VP of Agilian, which is part of the Sofeast group.

10. A-One Group Holdings – Hong Kong/Dongguan

American-owned and managed, A-One also provides PCB prototyping and assembly as well as mechanical prototyping, sourcing, and manufacturing, too.

- Key services provided:

- CNC Machining

- Plastic Injection

- Metal Forming

- PCB & SMT

- Design support services? No

11. Shape Prototype – Dongguan/Taiwan

Shape is an ISO 9001 certified facility which focuses on supporting hardware and IoT startups & SMEs with plastic and metal prototyping, small batch production, and more. Having said that, they have worked with very large companies such as Tesla, HP, and 3M. They have worked on AI & IoT & wearables, green tech, medical devices, and more.

- Key services provided:

- PCB Printing

- PCBA Manufacturing

- 3D Printing

- CNC Machining

- Urethane Casting

- Tooling & Injection Molding

- Milling & Turning

- Sheetmetal Forming & Stamping

- Die Casting

- Design support services? Yes, product design and development office in Taipei, Taiwan.

Traditional prototyping companies in China who focus on rapid prototyping using the designs they’re provided with

These companies will produce your prototypes based on the designs that you give to them. If you already have all of the product information ready to go and want support for China rapid prototyping, they could be in convenient and cost-effective options.

12. TeamRAPID – Hong Kong/Zhongshan

A two factory company specializing in rapid prototyping, CNC Machining, Rapid Injection Molding, and other low volume manufacturing. They have helped clients in the furniture, consumer electronics, and consumer goods, and doubtless, many more industries, get to market quickly.

- Key services provided:

- Rapid Prototyping

- Precision CNC Machining

- Rapid Tooling

- Injection Mold Tooling

- Pressure Die Casting

- Sheet Metal Fabrication

- Design support services? No

13. 3ERP – Zhongshan

3ERP provides one-stop rapid prototyping services & low volume manufacturing services. They are ISO 9001:2015 Certified and have created parts and prototypes for medical, automotive, aeronautical, and consumer products industries.

- Key services provided:

- Precision CNC Machining

- Vacuum Casting

- Rapid Tooling

- Injection Molding

- 3D Printing

- Rapid Metal Casting

- Sheet Metal Prototyping

- Aluminum & Plastic Extrusion

- Surface Finishing

- Design support services? No

14. Klarm prototyping – Guangzhou

Klarm have been in business for more than 10 years, are ISO 9001:2015 certified and produce high precision metal parts and large plastic products in a diverse range of industries such as electronics, automotive, machinery, medical devices, communication, sporting equipment, home applications, mechanical components, and more.

- Key services provided:

- Rapid Precision Machining

- High-volume Machining

- Plastic Injection Molding

- Silicone Vacuum Moulding

- Instant Pressure Die Casting

- Die Casting/Stamping

- Fast Sheet Metal Fabrication

- Design support services? No

15. NextProto – Zhongshan

NextProto was incorporated in 2015 and focus on CNC machining, rapid tooling, and plastic injection molding. They specialize in the Robotics, Automotive and Medical industries.

- Key services provided:

- Rapid Prototyping

- Sheet Metal Prototyping

- Rapid Injection Molding

- Aluminum Extrusion

- Investment Casting

- CNC Machining

- Design support services? No

16. Mold Making – Hong Kong/Dongguan

They specialize in the injection molding of custom plastic parts and have been in business since 1988. They have produced plastic molds and plastic parts for household appliances, medical equipment, electronics, safety equipment, and more. They also hold ISO 9001:2015 certification and use an ERP 9.0 system.

- Key services provided:

- Plastic Injection Molding

- Rapid Prototyping

- Low Volume Manufacturing

- CNC Machining

- Liquid Silicone Rubber Injection Molding

- Design support services? No

17. Prototech Asia – Zhejiang

This is a French company based not far from Shanghai. They focus on rapid prototyping and finishing, with experience in the automotive, electronics, food, consumer goods and many other industries.

- Key services provided:

- Precise Stereolithography 3D Printing Services

- 3D Metal Printing

- High-Quality Plastic CNC Machining Services

- Metal CNC machining

- Sheet Metal Prototyping

- Custom Extrusion

- Vacuum Mold Casting

- Plastic Injection Molding

- Design support services? No

18. HLH Prototypes – Shenzhen/Dongguan

Established in 2008, HLH has been offering a large range of prototyping and bespoke low volume manufacturing solutions all under one roof. They have created prototypes for a wide range of applications, including Aerospace & UAV. Automotive, Consumer Products, Industrial, Medical, and more. They have numerous certifications, including ISO 9001:2015, 14001:2015, IATF 16949:2016, and ISO/IEC 27001:2013.

- Key services provided:

- CNC Machining

- Rapid Prototypes & 3D Printing

- Injection Molding & Tooling

- Sheet Metal Work

- Die Casting

- Vacuum Casting (Urethane Casting)

- 3D Printing

- Finishing

- Design support services? No

19. SunPe – Zhongshan

SunPe, a large rapid prototyping provider with more than 500 staff which was established in 2005, has a special focus on the automotive industry but also works on products and parts in Home Appliances, Medical, Electronic, and Industrial Products, too. They hold ISO 9001:2015 certification.

- Key services provided:

- CNC Machining

- Vacuum Casting

- 3D Printing(SLA/SLS/Metal Printing)

- Block Modelling

- Die Casting

- Sheet Metal Prototype

- Extrusion

- Rapid Tooling

- Finishing

- Design support services? No

20. FirstPart – Zhongshan

FirstPart provides rapid prototyping, rapid tooling and low volume manufacturing and creates metal and plastic parts for clients in, for example, the automotive industry.

- Key services provided:

- CNC Machining

- Sheet Metal

- Cast Urethane

- Aluminum Extrusion

- 3D printing

- Plastic Injection Molding

- Pressure Die Casting

- Low Volume Manufacturing

- Finishing Service

- Design support services? No

21. An Prototype – Shenzhen

An Protoype has been in operation for around a decade. They provide typical rapid prototyping services and small batch production, notably CNC machining, vacuum casting, plastic injection molding, quality inspections, finishing, and more. They have a focus on creating parts for the medical, electronics, automobiles, robotics industries, amongst others.

- Key services provided:

- CNC Machining (including Aluminum)

- Rapid Vacuum Casting

- 3D printing

- Plastic Injection Molding

- Rapid Prototyping (Metal & Plastic)

- Design support services? No

22. BOLE Solutions – Dongguan

Since 2007, BOLE has built up a large business providing plastic and metal prototyping to some of the world’s leading brands such as Samsung, Siemens, Coca Cola, Life Fitness, in diverse industries including aviation, automotive, medical, construction, electrical and electronic, consumer goods, and more. In addition, they are ISO 9001 certified.

- Key services provided:

- Rapid Prototyping

- CNC Machining

- 5 Axis Machining

- Vacuum Casting

- Sheet Metal Fabrication

- Lathe Turn Milling

- 3D Printing

- Injection Molding Manufacture

- Design support services? No

23. Superior Prototype – Shenzhen

Superior prototype in Shenzhen holds an ISO 9001 certification and provide rapid prototyping solutions for various industries including digital communications, home appliances, medical, automotive, aerospace, and more.

- Key services provided:

- Rapid Prototyping

- CNC Machining

- 3D Printing

- Rapid Tooling

- Low Volume Production

- Sheet Metal Stamping

- Finishing

- Design support services? No

24. GS Proto – Shenzhen

Since 2003, GS Proto has been delivering precision prototyping and low-volume manufacturing services spanning multiple industries including automotive, medical, robotics, fibre optics, and more. They are also ISO 9001 certified.

- Key services provided:

- Design support services? Not really, but they provide a free DFM analysis

25. Starrapid – Zhongshan

Founded in 2005, Starrapid is a well established foreign-owned rapid prototyping, tooling, and production provider in China with ISO 9001:2015, 14001:2015 Certifications, and BS OHSAS 18001:2007 Certification. They have prior experience in consumer electronics, medical devices, consumer products, and others.

- Key services provided:

- Rapid Prototyping

- Rapid Tooling

- Plastic Injection Molding

- CNC Machining

- Vacuum Casting

- Pressure Die Casting

- Metal 3D Printing

- Finishing Services

- Design support services? Not really, but they provide a DFM review.

26. KG Model – Shenzhen

Shenzhen KG Model was founded in 2008 and provides metal and plastic prototypes for customers like Land Rover, Panasonic, Philips and Gree. They have been involved in work for clients in multiple industries including automotive, Medical Equipment, Lighting Products, Home appliances, Gifts, Watches, Kitchenware, Furniture, Aerospace, Military, Security, Simulation models, Toys and others.

- Key services provided:

- Rapid Prototyping

- 3D Printing

- CNC Machining

- Vacuum Casting

- Sheet Metal Stamping

- Metal Die Casting.

- Plastic Injection Molding.

- Low Volume Manufacturing

- Design support services? No.

27. Lexcent – Shenzhen

Lexcent serves some of China’s largest companies, such as Huawei and China Eastern airlines, and also international businesses, specialising in 3D printing, but also with CNC machining, and silicone molding capabilities to produce metal and plastic prototypes.

- Key services provided:

- 3D Printing

- CNC Machining

- Silicone Molding

- Design support services? No.

28. RP Group – Dongguan

RP was founded in 2012, is foreign-owned and managed, and holds ISO/IEC 27001:2015 Certification. They work with industrial design agencies, prototyping bureaus, medical equipment companies, automotive Tier 1, and OEM companies. Specialties include prototyping and production.

- Key services provided:

- Rapid Prototyping

- High & Low Volume Production

- 3D Printing

- CNC Machining

- Vacuum Casting

- Sheet Metal Fabrication

- Injection Molding

- Functional Prototyping

- Design support services? They provide a DFM review.

How to get a high response rate when asking for help to get a prototype made?

- Getting down to a clear concept, with documented requirements etc.

- Industrial design

- Some electronic and/or mechanical design work, to get the product to perform its function

- In some cases, a large amount of work to get the product to look good, too

That means they may be shocked when they discover the full cost of making a works-like and looks-like prototype.

In addition, the fact that they want to wait until they have a prototype in hand to start doing a structured market research exercise is a bad sign. Experienced teams start with that.

All this is proof that they are not very experienced and prototyping companies in China know it. It is probably their first time designing and developing a new product. Looking at the statistics of startups that make it all the way to a commercially successful product, the odds are relatively low…way below 50%.

Conclusion

Feeling lost, with so many options? Ask me for advice on the best fit for your needs

Get in touch with me by filling the form below and I will give you a tailored recommendation or quotation, including for prototyping in China if this is important for you. My company, Sofeast, can probably help you.