By Fabien Gaussorgues

Do you prefer to work with an OEM or an ODM? What are their pros and cons? And what is a CM?

This is particularly important if, as the importer, you want to develop a product that is different from what is already on the market. The advice in this article is especially suitable for mechanical and/or electrical products.

First of all, what do those manufacturer acronyms mean?

Here are simple definitions:

- Original Design Manufacturer: the supplier provides the design and already has the tooling (if any) necessary to manufacture that design. This is still an exception in China.

- Original Equipment Manufacturer (for a new product): the buyer asks the supplier to develop a new product (based on the buyer’s design).

- Contract Manufacturer: similar to OEM, but the supplier is typically open to manufacturing a wider range of products.

There is a special case. Let’s say the buyer selects an existing product (already made in the past by the factory) and requests only minor modifications (for example, a different color and a change in one of the minor components). Is it OEM or ODM?

The rule of thumb is, that it is ODM if the factory can use its own tooling; otherwise, it is OEM.

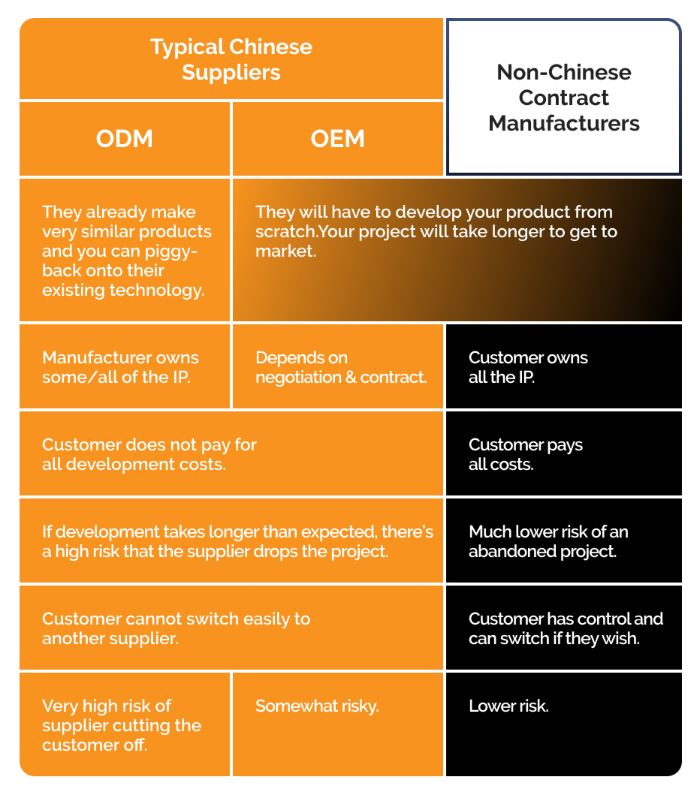

You can see how the three Chinese manufacturing supplier options compare in this graphic (to clarify, in this case, the CM is foreign-owned):

This illustration suggests there are no clear-cut delineations. However, there are enough similarities to reach a few conclusions.

Working with an ODM supplier

Selecting an ODM manufacturer is rather straight forward. You simply need to look for suppliers that have already made products that you can buy and sell on your market.

In most cases, the buyer will request changes. There is often a MOQ (Minimum Order Quantity) constraint based on the cost of processing those changes, and that MOQ can generally be negotiated.

Here are a few examples of changes:

- Place the customer’s logo on the product

- Change a material’s color

- Change the material type, for example replacing PU by real leather

Making some other changes is usually impossible:

- Different dimensions (especially when a mold is involved)

- Different features or performance — for example, making a blender with a stronger motor

Pros and cons of an ODM supplier

Pros:

- Shorter time to market

- Lower introduction price (since there are no R&D costs)

- Strong expertise in the technologies and (usually also) in the market space

Cons:

- Changing the supplier is difficult since they own the design.

- The buyer is taking a risk — how to make 100% sure the supplier didn’t steal the design from another company? For example, Amazon might ban your product and you might have penalties to pay.

- If your sales are high, the supplier will be very tempted to compete with you.

- If you gave them the inspiration to make a variation of their existing product and they think it is promising, they might make it without you… I wrote more on this topic in this article.

- You will probably have difficulties negotiating for favorable terms (payment terms, liability, etc.), since you are essentially just a distributor to them.

Working with an OEM supplier

To find a good OEM supplier, the first step is usually to look for a manufacturer that already makes products similar to those you need. Here is why:

- They know the assembly process

- They already have a supply chain (where to buy the materials & components)

- They already know the main risks to watch out for, as well as the testing procedures

There is an alternative option that many people overlook: using a CM (Contract Manufacturer). This is an especially good idea if assembling your product does not require very specialized processes.

A professional CM can bring the following benefits:

- Ability to optimize the production process beyond what you can expect from a Chinese OEM

- They focus on production only, not on distribution; there is less risk of having a CM sell to your competitors or to your customers (but that is a real risk with an OEM)

- The relationship is easier to manage, since they focus on production only

- You might be able to negotiate for transparency of sub-suppliers, which means you can’t be held hostage very easily

Pros and cons of an OEM supplier

Pros:

- Time to market is usually not very long if the OEM already makes similar products (they can use their current suppliers).

- Low R&D cost (for the same reason, development should not be very difficult).

Cons:

- Changing the supplier is not very easy since you need to change your entire supply chain (the new assembler will need new component suppliers, and many risks come with this) — remember, in most cases, a Chinese OEM will NOT disclose the identity of the sub-suppliers.

- Since there is no visibility on the cost at which components are purchased, it is difficult to negotiate for slow price increases.

- Since the sub-suppliers are not disclosed, they might be switched without reporting to the buyer. Material and/or process changes might have a serious impact on product quality.

- If your sales are high, the supplier will be tempted to compete with you.

- You might have difficulties negotiating for favorable terms (payment terms, liability, etc.).

Pros and cons of a Contract Manufacturer

Pros:

- The buyer is expected to own the design and to pay (and own) the tools.

- The buyer can often negotiate for visibility over the supply chain, which reduces many of the risks.

- Better control of the situation as a whole – cost, quality, and timing.

- Change from one CM to another is a relatively standard process.

- The CM generally accepts a certain amount of manufacturing-related liability.

Cons:

- There is more R&D work.

- Time to market is usually longer.

- The testing and validation plan should be defined from scratch and adjusted over time.

So, is it better to buy from an ODM, an OEM, or a CM?

If we try and come up with very general rules of thumb, they would be as follows:

- If you buy a very low volume and you need an MOQ of 500-1000pcs, go for an ODM.

- If you buy larger (but not very high) volumes, and you can accommodate an MOQ of 2,000 to 5,000 pcs, you may go for an OEM.

- If you buy in high volume (over 10,000 pcs), working with a Contract Manufacturer will be the best way to control your cost and your quality.

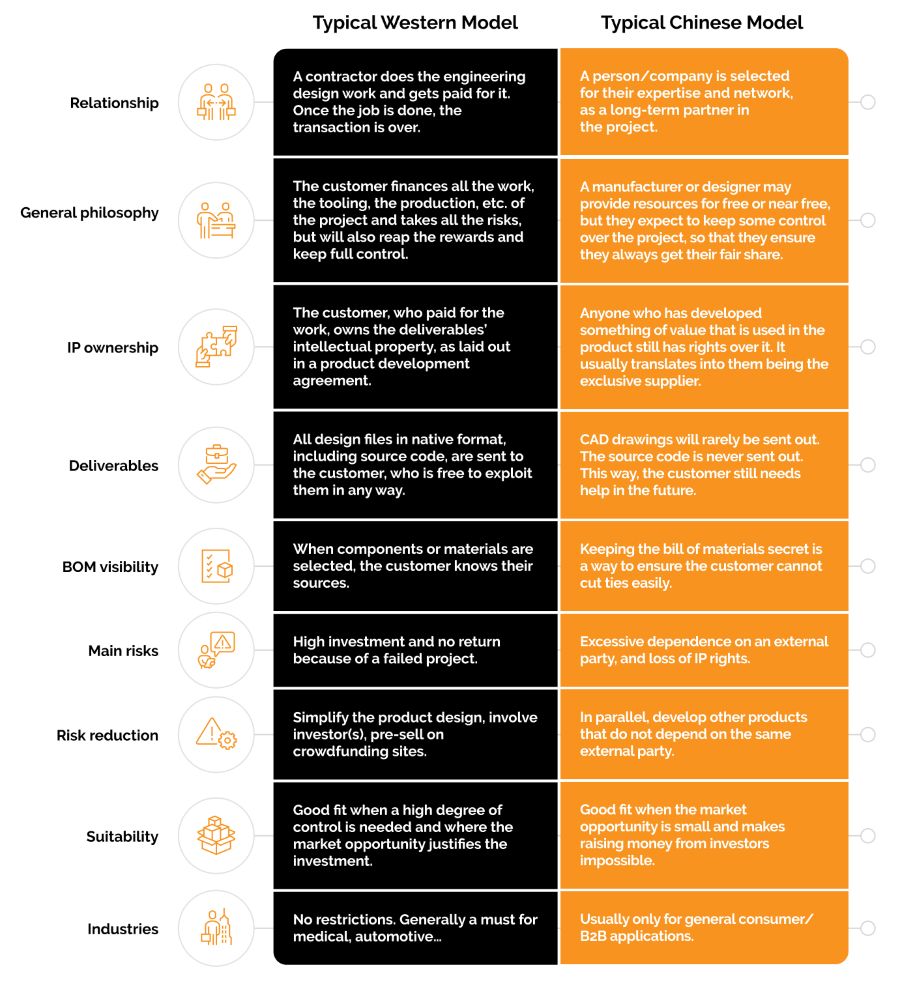

The manufacturer’s business model also matters

Many Chinese manufacturers will invest in developing your product using their own resources without charging you, but this doesn’t come for free. They will probably expect to own the IP they’ve been working on as ‘payment.’ This leaves you with a lack of control over your design, BOM, and their deliverables, as well as your product IP. That’s a typical ‘Chinese manufacturer business model.’

However, in China you can also find manufacturers, often CMs, who follow a more ‘Western model’ where you control the project, dictate what is worked on and when, and pay for each activity accordingly. As such, the CM becomes your ‘right-hand-man’ and carries out the product development and manufacturing for you while providing you with the product IP, sourcing information, etc, at every stage of the project.

Understandably, many foreign importers prefer to work with the latter supplier type if they can find one.

What about IP rights?

One might think the product’s intellectual property rights belong to the buyer in the case of an OEM deal.

In fact, it depends on the agreement you signed with the supplier! By default, Chinese suppliers will consider they own all the tooling, all the designs, etc.

The more complex the product, the more you need to think of the tradeoffs we have explored in this article. This is particularly relevant for ‘IoT’ products, and many electronic products in general, as Steve Dickinson pointed out on the China Law Blog recently:

In most of the IoT projects we have done, the development process has expanded to include the following:

1. Product “concept” from the foreign (usually United States or European) buyer.

2. Product external design, from an international design firm.

3. Internal design and function, owned by:

a. The foreign buyer;

b. The Chinese manufacturer;

c. The provider of sensors and other components required to connect the IoT product to an outside network.

4. Design of the IoT product “app” (usually for smart phones). This involves two completely separate sets of software: the communication sending software residing on the IoT product and the communication receiving software residing in the application. In the same manner as the internal design, these software components may be written/designed by multiple parties: the foreign buyer, the Chinese manufacturer and (quite often) third party software design firms.

—

What do you think? What kind of supplier are you working with right now?

Are you wondering how to find a manufacturer in China who is well-suited to your needs and can also deliver on their promises?

Sofeast has developed 10 verification steps to help you find the right manufacturer. They’re shared in this FREE eBook: “How To Find A Manufacturer In China: 10 Verification Steps.”

It covers:

- Background checks

- Manufacturing capabilities

- Quality system auditing

- Engineering resources

- Pricing, negotiation, & contracts

- …and much, much more

Just hit the button below to get your copy: