Do you find yourself with some time on your hands, when your Chinese suppliers are enjoying their New Year holiday?

Why not take advantage of it and do some work that will be important to your company’s success?

Here are 4 suggestions.

1. Data analyses for better decisions

If you can easily extract all the issues from QC reports (or if you can use an intern to do that work), this will be well worth your efforts.

Ideally, you would classify the past issues per product, per supplier (and per factory if possible), and per month.

Then you can plot them on a few graphs. Here are a few examples:

- A Pareto chart of the most common issues per product, per factory

- Evolution of the frequency of occurrence of the 3 most common issues, month by month, for each factory

- Compare your suppliers on a few KPIs such as % defectives, % of batches with serious issues, number of corrective action requests, average time to close a corrective action request

This information can help you put pressure on some suppliers, and ask them to improve in some very precise areas.

2. Building a supplier management system

Now that you have a few KPIs related to quality, why not work with your colleagues from purchasing… and help them do the same?

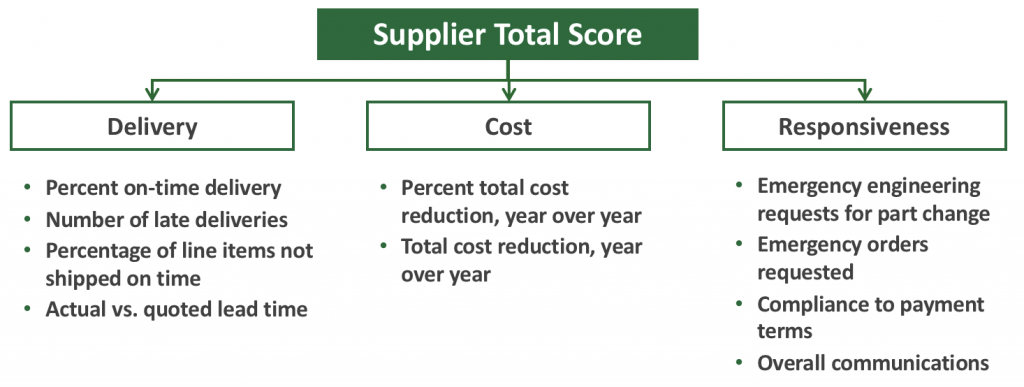

Here are some other KPIs your company could collect:

Now the purchasers are armed with a set of KPIs that go way beyond what they’d naturally tend to look at (the FOB price).

Another benefit is, the simple fact that a supplier knows you are tracking them will push them to take actions to improve. It is human nature. They might not take the right actions, or not apply them in the right proportions, but they will probably try something.

3. Improve your checklists and other work instructions

I bet you often need to repeat the same things over and over. For example, you are asked to validate QC reports that raise an issue but don’t a clear-cut “passed” or “failed” result simply because the checklist was not clear.

So, why not review the documents most often used and update them? You will certainly have many things come to your mind as you read them. Add examples (if possible, both good and bad), special cases, escalation procedures, etc.

4. Other suggestions

Many people in importing businesses feel the manufacturers and the testing/inspection houses should work on their internal quality systems. But in reality importers also need to get their house in order.

For example, are your approved samples well catalogued and in good condition? How about your testing/measuring equipments, are they well maintained and calibrated?

Do you talk regularly to your company’s customers, gather their feedback, and draw a few insights for top management?

Maybe the best you could do is familiarize yourself with the main production processes involved to make the products you buy. These days there are many good Youtube videos on the most common processes. As you watch them, ask yourself: ‘what are the key process controls that I should ask my suppliers to report on, to ensure they know what they are doing?’

—

What do you think? Any other ideas?