![Sampling plan calculations for quality inspections [infographic]](https://qualityinspection.org/wp-content/uploads/2011/02/UPshutterstock56722456.jpg) Most inspections only involve 1 or 2 references, and can be conducted in one man-day (i.e. one inspector on site for one day). However, in certain situations, deciding on a sampling plan is very difficult–see my previous article about shipments including many references.

Most inspections only involve 1 or 2 references, and can be conducted in one man-day (i.e. one inspector on site for one day). However, in certain situations, deciding on a sampling plan is very difficult–see my previous article about shipments including many references.

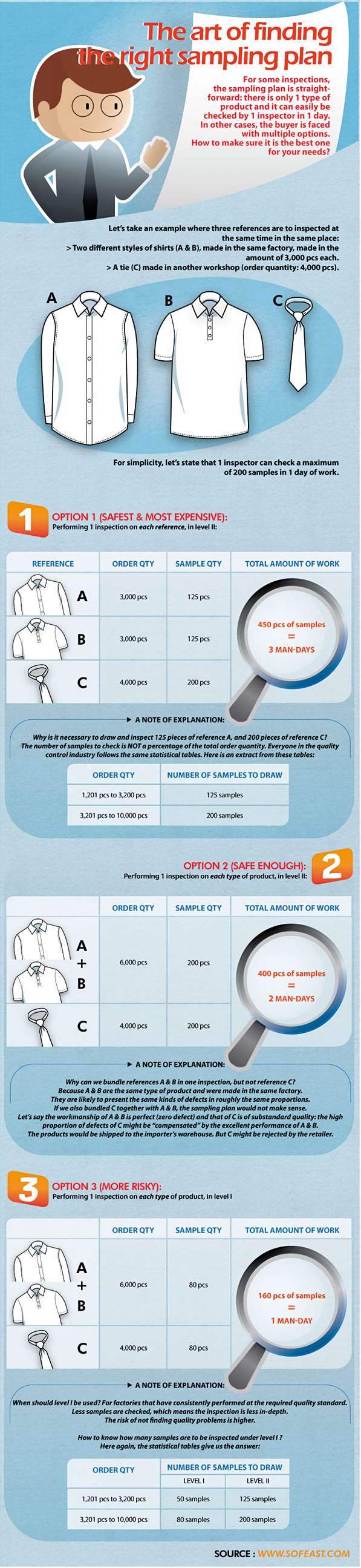

This is one of the most difficult things to explain to my clients. Fortunately, my designer managed to explain it all nicely in this illustration:

Related resources:

- To see the whole statistical tables, you can go to AQL tables.

- To understand how to read these tables, you can read Get familiar with AQL tables.

Does this illustration do a nice job of clarifying this issue?

Great website!

Can anybody help?

We have 6 shipping containers containing 585 items / boxes each of the same item for a total of 3510 items / boxes. We strongly suspect a high rate of defective products in the shipment but assume the high defect rate is limited to 1 or 2 batches (therefore only present in 1 or 2 containers).

If this assumption is correct, how many items / boxes do we need to open and inspect for each shipping container to give us 98% confidence that that container has an acceptable amount of defects (2% defect rate as opposed to 30% defect rate)?