I have covered at length how to use statistics to accept/refuse a batch of product based on a random sample. Those statistics are usually the only ones the typical production manager has ever come in contact with!

I have visited hundreds of Chinese factories. And, outside of the auto industry, I don’t remember ever seeing any trace of statistical process control.

Can statistical tools be used to improve production processes? Yes. Are they always useful? No. The difficulty is to know where and how to use them.

One extra obstacle is the mindset of the production staff. If they have no interest improving their processes and they only want to ship product out (and rework it if the customer’s inspectors reject it), their habits and ways of thinking need to change first.

At CMC we have prepared a webinar on this topic: How Statistical Process Control Helps Reach Six Sigma Level of Quality.

My partner David Collins, who has 30 years of manufacturing experience and has managed multibillion dollar factories in the past, explains how SPC can be used in China.

This webinar covers the following topics:

- What statistical process control is

- What ‘process thinking’ and ‘system thinking’ mean

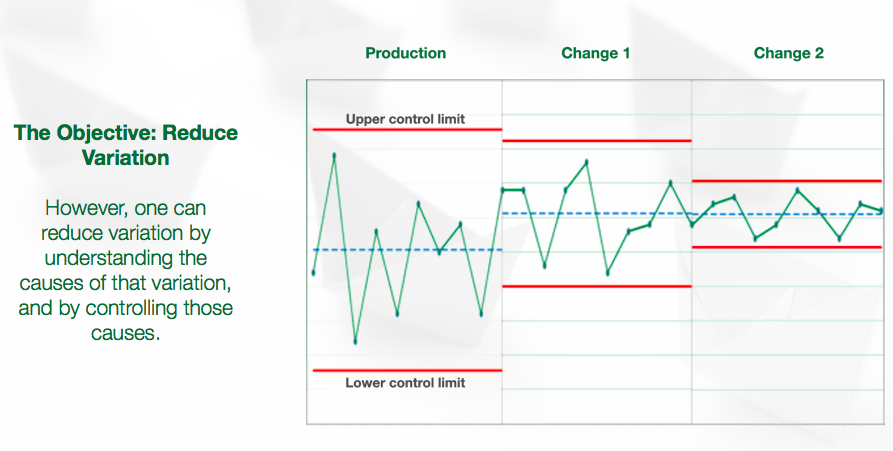

- Process variation, and how to reduce it

- Which variables must never be ignored

- What six sigma is

- 5 key best practices you can adopt to reach six sigma levels of quality

If you are a buyer, it can help you understand some of the differences between world-class factories and average workshops.

If you are a manufacturer, it can lead you down the right path to improve your quality cost-effectively.

To register and learn about statistical process control, click here!