Do you sometimes feel that your company, your suppliers, and their own suppliers, are on different planets? Does information spread with difficulty through your supply chain?

Nothing unique here. It is quite typical if you work with suppliers in China, Vietnam, India, etc.

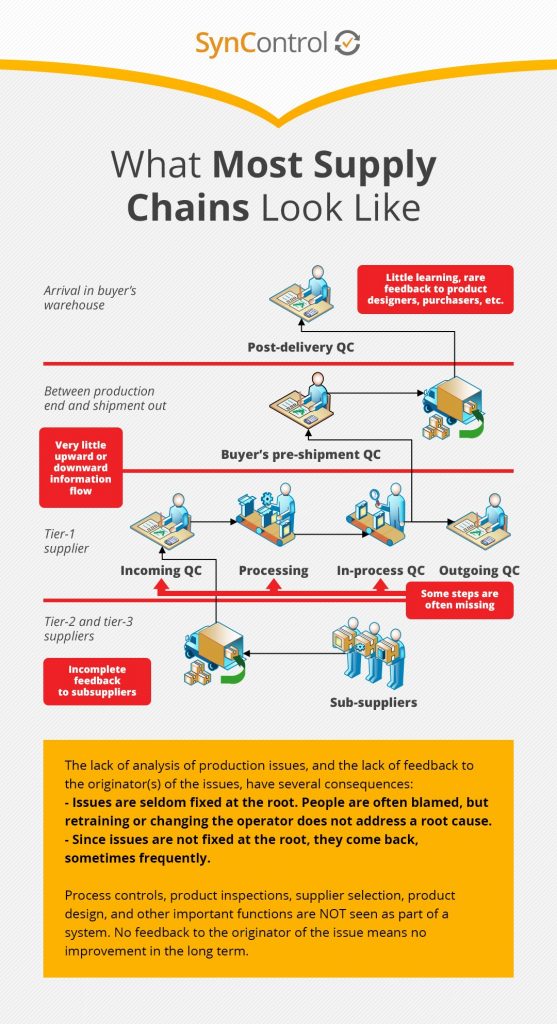

I wrote about this in The Impact of Quality Control Software on Your Supply Chain, on the SynControl blog, and we illustrated it in this infographic:

Every step in the supply chain tries to optimize its own situation. There are serious breakdowns in the transmission of information. There is nearly no feedback loop, no followup on improvement, and in the long run, it means mediocre performance.

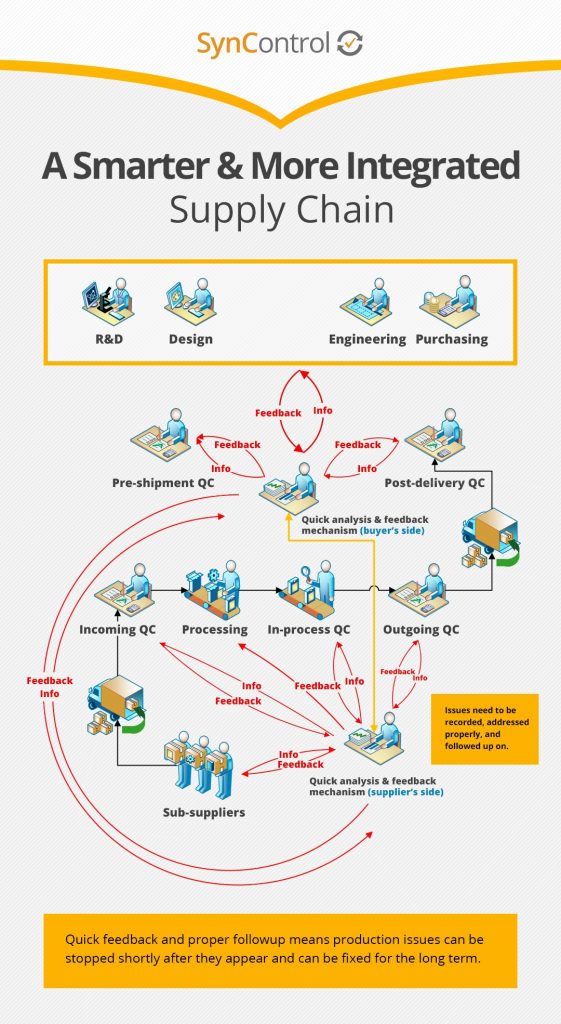

We also drew this vision of a much better setup, with a particular emphasis on QC inspections (hey, that’s our line of work).

Software is not enough. Obviously, the importer needs to negotiate a certain level of visibility and access to the critical sub-suppliers and needs the exporting factory to be open about their internal processes.

It also requires some good communication within the buying organization. If no department pays any attention to the issues and tries to improve, all this is pretty much useless.

Does it make sense?

Sofeast: Quality Assurance In China Or Vietnam For Beginners [eBook]

This free eBook shows importers who are new to outsourcing production to China or Vietnam the five key foundations of a proven Quality Assurance strategy, and also shows you some common traps that importers fall into and how to avoid or overcome them in order to get the best possible production results.

Ready to get your copy? Hit the button below: