Once the products hit your dock and once you have paid 100% of the order, there is little you can do in case products are not up to your specifications.

Chances are, you have already paid the supplier in full. And the supplier will certainly not give your money back, or re-produce for free. (It does happen, but very seldom.)

That’s why professional importers generally have every order inspected before shipment. (Chinese factories are famous for cheapening the product when the buyer starts feeling more confident.)

1. When does a final inspection take place?

It takes place once 100% of the shipment quantity is finished and when most products (the limit is usually ‘at least 80%’) are packed. This way, the cartons can be counted and the quantity can be estimated.

The big advantage is that samples can be taken at random — the manufacturer cannot hide a large portion of the products in a back room and pretend all the goods are in front of the inspector.

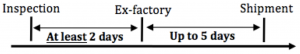

Make sure you have a few days between the final inspection and the deadline for giving the green light for shipment:

The manufacturer might have to do minor corrections on the packing or the labelling, for example, and you might need them to send you a few photos and explanations before you make a decision.

2. Where should a final inspection take place?

It is usually conducted in the factory. This way, if re-work is needed, the manufacturer can do it right away.

It is important for a representative of the supplier to understand what (if anything) went wrong. Typically, the inspector(s) asks the supplier to sign on the list of problems found.

Conflicts sometimes arise. But, in most of these cases, the buyer hasn’t taken the time to define clear specifications (see post 7). If the quality standard is clear, there should be no surprise and no argument!

3. What is checked in a final inspection, and can’t be checked earlier?

In the previous part of this series, I listed the benefits of an inspection during production, but a final inspection is usually necessary as a complement, for the following reasons:

- As I wrote above, the presented quantity can be estimated, which means the inspector can pick samples that are representative of the whole batch.

- The inner packaging, the export packing, and the labelling are usually added to the products a few days before shipment. They are essential to protect the products and to ensure smooth handling along the supply chain.

Typically, your spec sheet will become the inspector’s checklist. Every aspect of the product and its packaging can be checked/tested if the factory allows it and provides the necessary equipment.

As a consequence, most quality control jobs are performed a few days before shipment, rather than during production. For example, if I look at our clients’ bookings, over 70% of all inspections are final inspections.

4. The statistics used in the quality control industry

Whether you appoint a professional quality assurance agency, or you handle this internally, it is good to know what statistical rules are used in the industry. You should know more about it than your suppliers, or their interpretations might confuse you.

- You can understand how to read the AQL tables here.

- You can get the most commonly-used AQL tables here.

5. What to do when a big problem is noticed at that stage?

First, as I advised in part 6, you should definitely make sure quality is acceptable before you pay the remainder of what you owe your supplier. Do NOT play it nice and “build some goodwill”. That’s a mistake I have seen many first-time buyers make. Keep a part of the payment until they have done the corrections you required.

Then, there are several cases:

If you estimate the manufacturer can simply sort the bad pieces out, or re-work some bad pieces, then you should follow the procedure I outlined here.

If you need the supplier to analyze what the origin of the problem is and to report it to you, you can ask them to prepare a CAPA form (see an example here).

If the manufacturer doesn’t take action on the root of the problem, or if you feel that they are going in the wrong direction, you need to take action. You need to send an engineer who is familiar with the factory’s process to discuss with their technicians.

That engineer should look for the root cause, propose countermeasures (while taking into account the manufacturer’s suggestions), and try to run a test while he is in the factory.

If ever you need that type of help, contact me and I will try to send you in the right direction.

—

As this last paragraph suggests, communication with the supplier is very important. Many importers cite lack of communication and poor communication as the main sources of problems.

We will cover this topic in the next part in this series, part 11.

>> Move on to the next post in this series. Read it here: Sourcing from China 101, Part 11: Build Good rapport with Suppliers <<

Are you trying to find a manufacturer in China who is well-suited to your needs and can also deliver on their promises?

Sofeast has developed 10 verification steps to help importers find the right manufacturing partner in China. They’re shared in this FREE eBook: “How To Find A Manufacturer In China: 10 Verification Steps.”

It covers:

- Background checks

- Manufacturing capabilities

- Quality system auditing

- Engineering resources

- Pricing, negotiation, & contracts

- …and much, much more

Just hit the button below to get your copy and put yourself in a great position to get better results from Chinese manufacturers who supply your products: