In this episode... In episode 65 we discussed the different supplier options open to buyers who’re sourcing from China. One of the options is to do the sourcing yourself. Many importers want to pursue this, so we're creating a mini-series … [Read more...]

Sourcing from China 101, Part 15: How To Improve Factory Productivity

This is the last part in this 15-part series. Here we'll focus on how to improve factory productivity in China. Why is it important for buyers? Because, unless your suppliers make progress in this area in the next 5-10 years, many of … [Read more...]

Sourcing from China 101, Part 14: How To Improve A Factory’s Quality

I bet you are tired of hearing your Chinese suppliers say “this is made by hand, so avoiding defects is impossible”. So am I, because it’s so wrong. Some small factories have decreased their defect rate below 50 parts per million … [Read more...]

Sourcing from China 101, Part 13: Developing a Chinese Supplier

Many importers work in one or two product categories. They buy 80% of their volume from 1-4 manufacturers. And many of them make the same mistake: they don’t try developing a Chinese supplier who they are CURRENTLY working with. Instead, … [Read more...]

Sourcing from China 101, Part 12: How Closely To Follow Production?

Up until now, I have written advice that is targeted at certain types of importers. I call them the “hands-on buyers”, and I know them well because many of them are our clients. They tend to follow their production closely. However, … [Read more...]

Sourcing from China 101, Part 11: Build A Good rapport with Suppliers

Up until now, I have written lessons about “hard” issues: screening suppliers, writing specifications, negotiating the right terms, and inspecting quality. But I feel I should take a moment and focus on “soft” issues, and in particular, … [Read more...]

Sourcing from China 101, Part 10: Always Verify Quality Before Shipment

Once the products hit your dock and once you have paid 100% of the order, there is little you can do in case products are not up to your specifications. Chances are, you have already paid the supplier in full. And the supplier will … [Read more...]

Sourcing from China 101, Part 9: Check Quality Early In Production

I’ll assume you have found and audited a good manufacturer. They have communicated well up until now, and you feel confident about them. But should you feel confident? Several things can go wrong: They might be too busy and farm … [Read more...]

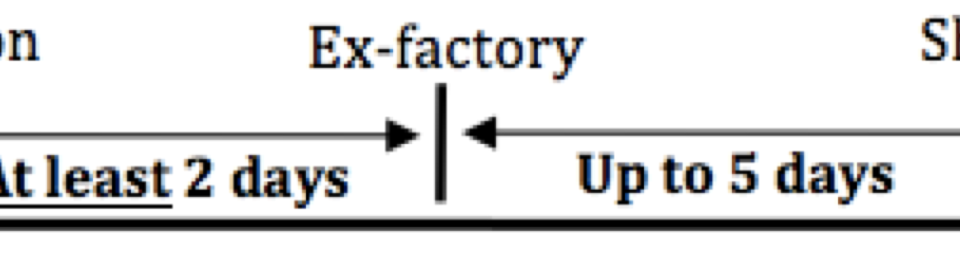

Sourcing from China 101, Part 8: Project Management of Your Orders

One recurring theme in this course is that you should not rely on the supplier’s salespeople. Most of them would have been hired solely on the basis of their English skills. They are interpreters with very little technical knowledge, and … [Read more...]

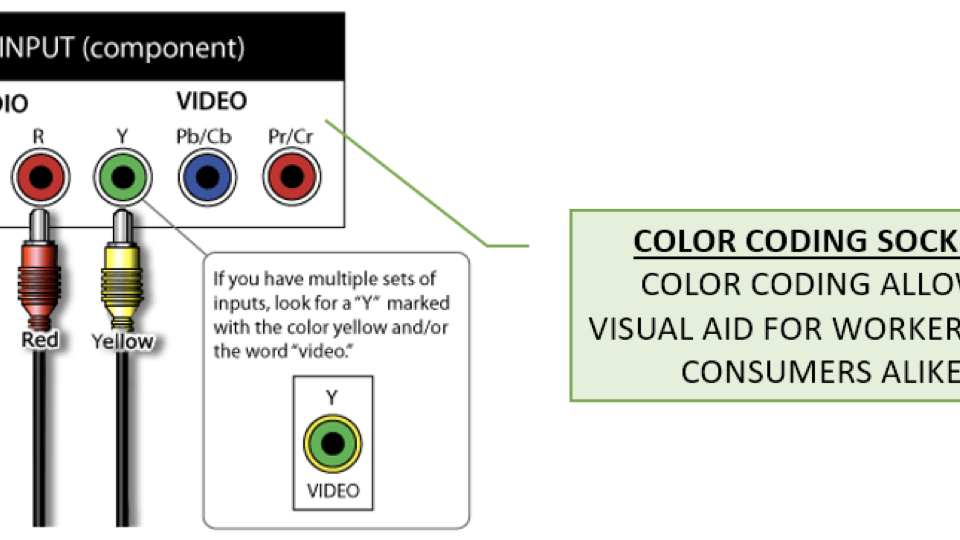

Sourcing from China 101, Part 7: Pre-Production: Describing What You Want

I have stated several times that you need to describe your product in detail. I know this is obvious, but most buyers don’t do is well… and often regret it later. There are two ways of formalizing your requirements: A written … [Read more...]

![Sourcing from China (Part 2): Negotiating terms, leverage over suppliers, and describing your needs. [Podcast]](https://qualityinspection.org/wp-content/uploads/2021/10/SourcingfromChinaPart2Negotiatingtermsleverageoversuppliersanddescribingyourneeds.Podcast-960x628.jpg)