Whenever I am in front of a Chinese factory owner, the dialogue goes like this:

Whenever I am in front of a Chinese factory owner, the dialogue goes like this:

Me: “you know, you can drive your costs down significantly simply by re-organizing your production.”

Chinese boss: “Hmmm… I don’t know what you are talking about. We’ve been doing this way since the beginning, and it works fine. All my competitors do the same. I don’t know of any other way”.

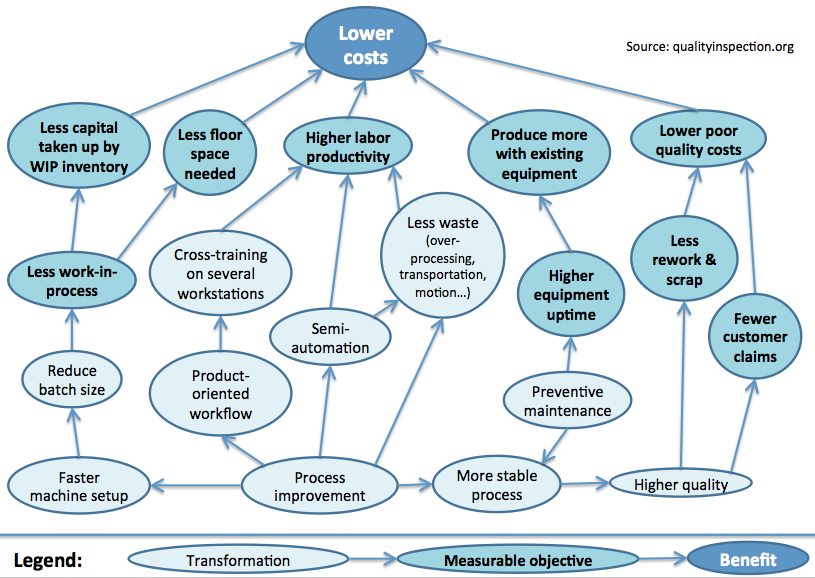

It can be frustrating to explain how it works, and sound idealistic. There are cause-and-effect relationships, and they make sense. So I tried to make it simple and visual.

How a lean transformation drives costs down

Is it simplistic? Yes, sure. It can’t be pulled out in a few days — this type of transformation can take more than a year, and is never completely “over”.

Is it over-simplistic? I don’t think so. It looks like the right visual aid to explain lean to someone who was never exposed to it before.

I also like the fact that it is all dynamic. It is actually a never-ending process. Stop working this system, and you slide back slowly (entropy is at play).

Does it work?

When applied correctly, it does cut costs significantly. Simply looking at labor productivity, gains are often in the 30% range.

In the last example I read, GE was able to make a water heater in the US for 20% less than the price they paid in China!

Some books relate tens of examples of successful lean transformations: Gemba Kaizen, Becoming Lean, and probably many others.

Why most Chinese manufacturers don’t get it

As I wrote a few months ago (in Why few Chinese factories are adopting lean principles), I can see four reasons why Chinese bosses don’t make any effort in improving their production processes:

- A total ignorance of (and lack of curiosity about) best practices.

- The whole supply chain pushes them to the batch-and-queue system: customers who want to buy full container loads, sub-suppliers who give discounts for big orders.

- A fascination for full automation, and a lack of interest in re-thinking processes.

- A basic lack of respect for workers in many workshops.

However, more and more examples demonstrate that lean principles can be applied in a Chinese culture. Some of the large automotive plants have succeeded, but they are not the only ones.

Even a small factory such as Easybox and its 160 workers in Foshan managed to apply lean principles. They are so productive, they staff generally doesn’t do overtime and gets a bonus (contingent on the achievement of the production plan) instead. And they have no MOQ (read about other benefits of lean here).

I’d love to confront my experiences in this field with those of my readers. Please comment!

There are too many competitors in same field, in order to keep the business some fty are “forced” to accept 1 pcs order( really super small order), but I am interested in unit price of 1 pcs. Normal qty 5000 pcs is $2.00/pc, then 1 pc in……….$200?….$2000?…..$20000?

In the case I mention in this article, they are happy with any size of order. Their lean organization makes it as economical to produce 1 piece or a batch of 10,000 pieces. The price is not higher for a smaller quantity.