I guess most of my readers work in a service business (importing company, trading company…).

I guess most of my readers work in a service business (importing company, trading company…).

Did you know that service activities tend to be more inefficient than manufacturing activities, for the simple reasons that (1) one doesn’t easily follow the flow of information, (2) one doesn’t always see work-in-process piling up, and (3) defects are seldom counted.

If you want to work more efficiently, I suggest to read Lean Six Sigma for Service : How to Use Lean Speed and Six Sigma Quality to Improve Services and Transactions, by Michael George.

This book focuses on important topics such as:

- How to recognize non-value added tasks and remove them from the normal flow,

- How to recognize and reduce complexity, to achieve substantial savings and reduce defects,

- How to standardize or modularize services in order to keep offering a wide array of services and satisfy more customers.

I reproduced one of the most interesting parts of the book below.

Example of creating a pull system in a service activity

The independent distributors for one company needed to get proposal information from the marketing department in order to quote construction jobs. The distributors were unhappy with the 2 to 3 weeks it took marketing to develop the needed information.

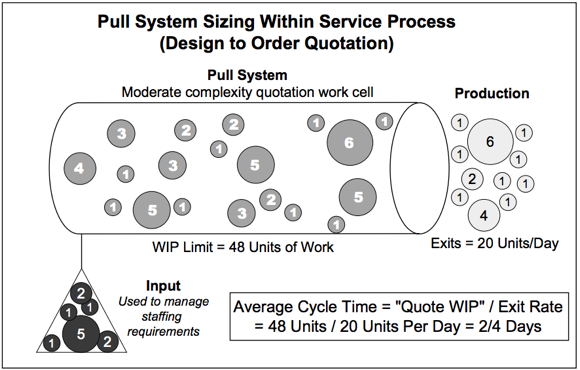

The required turnaround to delight these customers was 3 days. A team collected data over a few weeks that showed the marketing staff could process an average of 20 quotes per day. The distributors wanted a reliable 3-day turnaround; the data showed that because of variation in the process, the marketing staff would have to aim for a target closer to 2.4 days in order to meet that customer request.

How much WIP could they allow in the process? They turned to Little’s Law and plugged 20 into the completion rate and 2.4 days into lead time, to come up with a maximum WIP of 48 quotes in process at any time:

To manage this system, they created a visual board that showed how many quotes were in process. The cap on WIP was 48 requests, so unless the number dipped to 47, no additional quotes could be delivered by the clerk.

In other words, a Pull system in service environments means making deliberate decisions about the timing of work released into process. Just how you make those decisions is critical; it gives you another opportunity to live out a focus on “value.” For example, in this case the question was which request will be released into the process when another request is completed. “First in, first out” didn’t cut it here because some requests represented highly likely, high-dollar-potential orders; others were much less likely to be accepted, represented difficult bids, or were for smaller orders.

The answer lie in triaging the bid opportunities. Each request was rated on a scale of 1 to 3 on each of three criteria:

• Difficulty to bid

• Competitive advantage

• Gross profit dollars

The scores for each criteria were multiplied for each bid opportunity. Those with the highest rating would be the next to be released into the process—even if there were other bid opportunities that had been waiting in line longer. (So a new request that scored a 9 would be released before an older request that scored a 6.) Using this system, the same number of marketing staff were able to book 70% more revenue and 80% more gross profit. (An alternative, of course, would have been for this company to hire a lot more marketing staff—at great expense—so they could increase capacity.)

You can buy the book on Amazon by clicking here.

I found the proposal Pull System example to be very interesting.

Two days ago, our CEO (www.hcea.asia) was in a similar meeting with an installer of LED solutions in Europe. Their marketing department had 160 outstanding quotes as a result of waiting on their service engineering estimation team to get the needed product information from various competing manufactures in China. The China-Europe time difference was also increasing their delays, ultimately causing a bottle-neck in thier proposal process.

It was clear that increasing number of team members in Europe was not the solution, but rather we needed to change the way we received this information from China.

Therefore, it has been decided to set up a process for estimates and design between the European company and the Asia manufactures that is more automated. We are now quickly putting in place a process of communication elements between the two entities and are looking for a Service Company in Asia that will research manufacturers and gather the pricing requests during Asian working hours. Thus, in the future, the LED solutions provider in Europe will have the Asia Service Company working during the daytime in Asia / overnight in Europe to provide the needed information before the start of the business in Europe.

Jennifer Peterson jpeterson@hcea.asia

It’s funny to see that the author’s example is a very widespread problem. Thanks for sharing your experience, Jennifer.