Let’s say you intend to conduct a final random QC inspection, after all the products are packed.

Let’s say you intend to conduct a final random QC inspection, after all the products are packed.

(I already explained why the whole order should be ready for final QC).

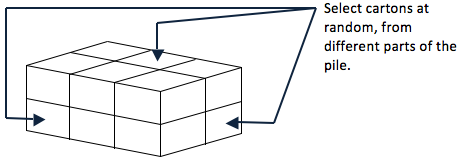

You need to select a few cartons at random. What are the best practices to ensure that the samples you will check represent the whole batch?

1. Don’t come if nothing is packed.

When the manufacturer is rushing the job and products are still under production (or rework), it is impossible to do a good job. You will never be sure that your findings are representative of the whole order.

You cannot count how many pieces are on the lines. And chances are they will not let you interfere with their production processes.

2. Make sure you can count and pick cartons randomly

If the warehouse is full and the factory prepared this kind of pile, you are in trouble.

It is impossible to separate each reference in a different pile, because of lack of space. Good luck to pick cartons from all sides of the pile…

You’ll need to insist heavily on this point before going for the inspection. Sometimes they will make an effort for you when they stack the cartons up.

3. Pick cartons in a “stratified random” manner

If 100% of the cartons are ready and they are nicely stacked, you can use the packing list to select the carton numbers: 3, 10, 17, 23, 32, and so on. Two pieces of advice:

- Avoid no arithmetical series in the list of numbers you select (2, 4, 6, 8).

- The number of picked cartons should be at least the square root of the total number of cartons.

However, most of the time this is not practical. Warehouse workers spend a lot of time searching the right carton numbers because their pile is a mess!

Most of the time, QC inspectors follow this logic:

Then the factory workers take the cartons that were selected, and bring them to the inspection area (under the inspector’s supervision, of course).

4. Following step: pick the products

In many cases, there will be more products in the inspection cartons than the number of inspection samples you need to check.

The same logic applies: don’t take all the products in one carton, or in the same place inside the cartons.

Is it clear?

Have you encountered this same experience? I had found the empty cartons &

the wrong product packed inside the cartons from the whole patch, when I took QC inspection in my China supplier’s factories? I strongly believed that they intended to

cheat me, since they confirmed me 100% of cargo ready for inspection before.

I really didn’t understand why they would done it so idiotic!!!

Don,

Yes, sometimes it happens. An entire part of the pile is just empty cartons. That’s why we must pick them randomly, from all parts of the pile, and then make sure the cartons are not switched on the way to the inspection room.

This is an example of real, serious control, Renaud. I appreciate you sharing this. To many importers, they may think you are being “picky”, but it takes one good time of being burned for them to realize the seriousness of inspections and assurance. I appreciate all the education you continually share from this blog. Have a great weekend there down South…South China that is…the other South.

Very good sug. i appreciate you for sharing this.

Thanks Rajib!

Awesome article and a great reminder. I sent this link to all my inspectors in China.

wonderful site to learn.